Air-locking discharging device

A technology of unloading device and air lock, which is applied in the direction of transportation, packaging, loading/unloading, etc., can solve the problems of uncontinuous feeding, coal consumption, power consumption increase, restrictions on continuous release of hazardous waste and air lock, etc., to achieve Avoid health risks and safety risks, improve stability and safety, and realize the effect of automatic continuous feeding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention is described below based on examples, but the present invention is not limited to these examples. In the following detailed description of the invention, some specific details are set forth in detail. The present invention can be fully understood by those skilled in the art without the description of these detailed parts. To avoid obscuring the essence of the present invention, well-known methods, procedures, procedures, and components have not been described in detail.

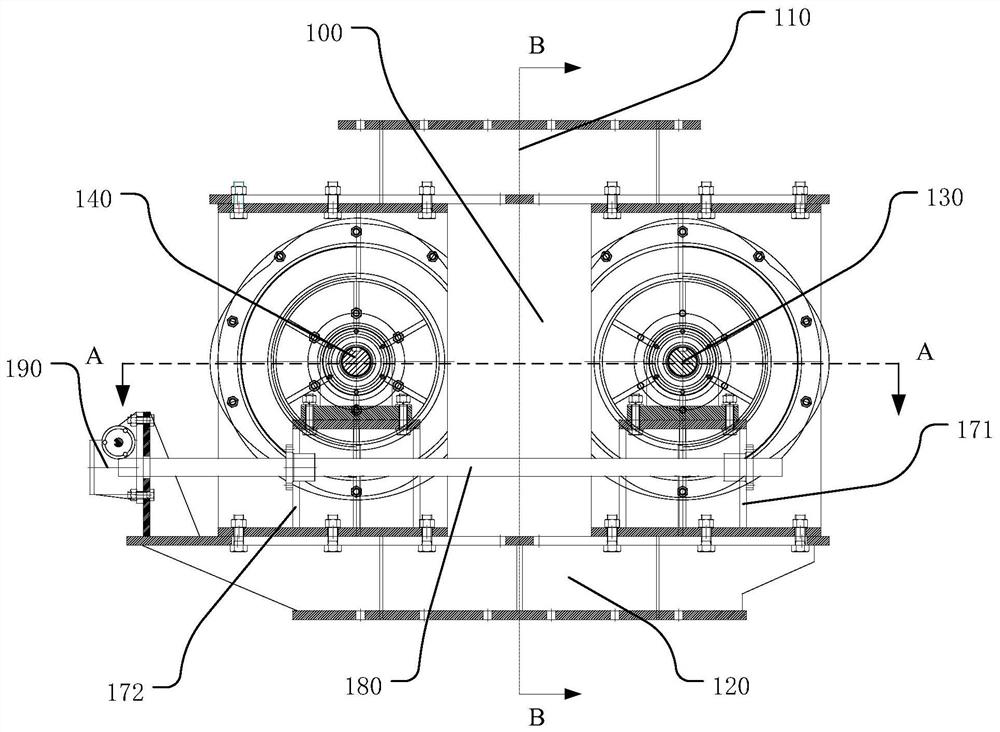

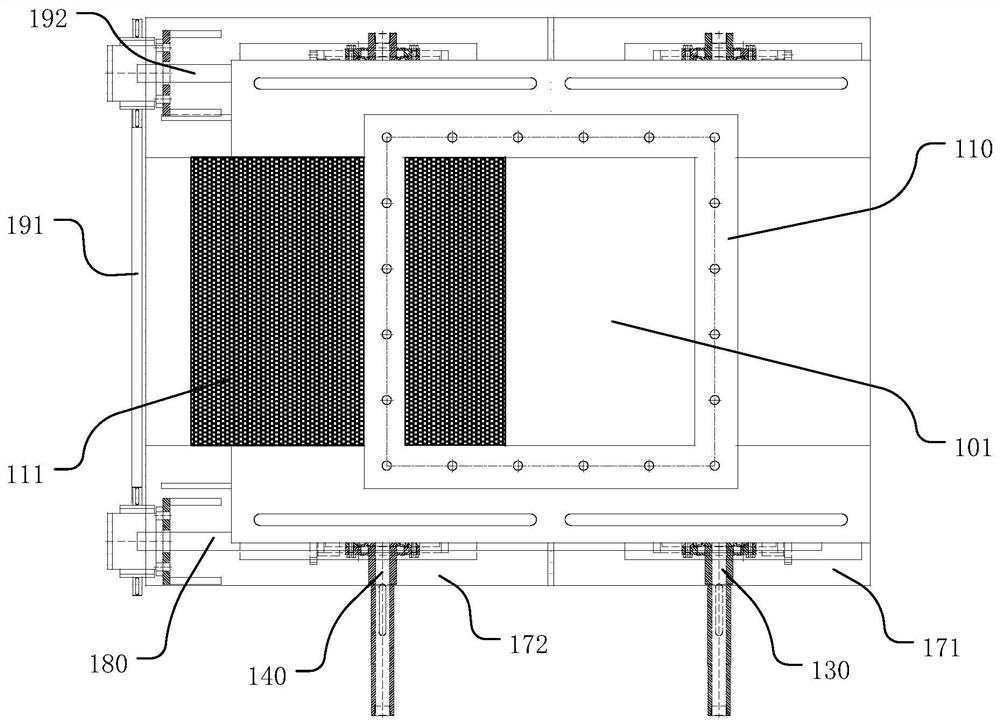

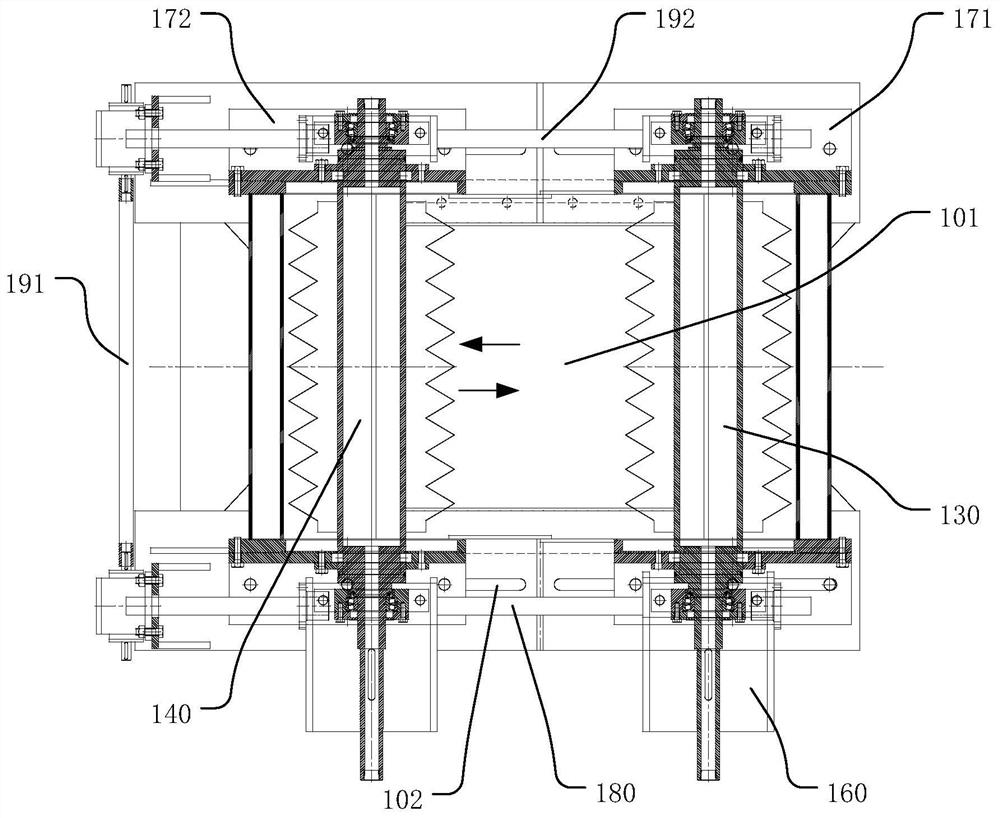

[0030] figure 1 and figure 2 A schematic diagram and a top view of the wind lock and discharge device according to the embodiment of the present invention are respectively shown. The windlock discharge device includes a main body 100 , a first discharge roller 130 , a second discharge roller 140 , a first support frame 171 , a second support frame 172 , an adjusting screw 180 and a synchronous structure 190 . Wherein, the main body 100 includes a cavity 101 for accommodating ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com