Double-stage air lock apparatus for ash discharge port

A technology of ash unloading device and air lock, which is applied to the separation of dispersed particles, chemical instruments and methods, and filtration of dispersed particles. Good wind performance and power saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

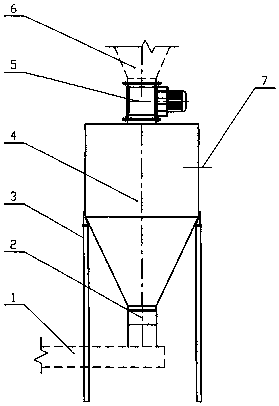

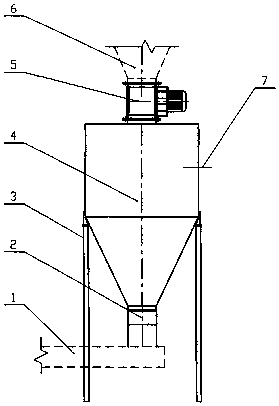

[0014] The specific embodiment of the present invention will be further described below in conjunction with accompanying drawing:

[0015] A rigid impeller feeder 5 is installed below the ash hopper 6, and the middle is sealed with a rubber gasket to realize a first-level air lock. Considering the problem that the first-level air-locking device cannot achieve complete sealing, a storage bin 4 is added below the rigid impeller feeder 5, and the middle is sealed with a rubber gasket to achieve a second-level air-locking.

[0016] The storage bin 4 is supported by the bracket 3, and the secondary ash unloading device 2 is connected below the storage bin 4.

[0017] A material level gauge 7 is arranged in the storage bin 4 .

[0018] The dust collected by the dust collector in the ash hopper 6 is first sent to the storage bin 4 through the rigid impeller feeder 5, and at this time, the secondary ash unloading device 2 and the conveying equipment 1 are both in a stopped state. Wh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com