Gravity locking valve for dust collection of boiler

A technology of gravity lock and boiler, applied in the field of air lock valve, can solve the problems of lax closing, deformation of valve head connecting rod, air leakage valve head, etc., and achieve the effect of environmental protection and energy saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

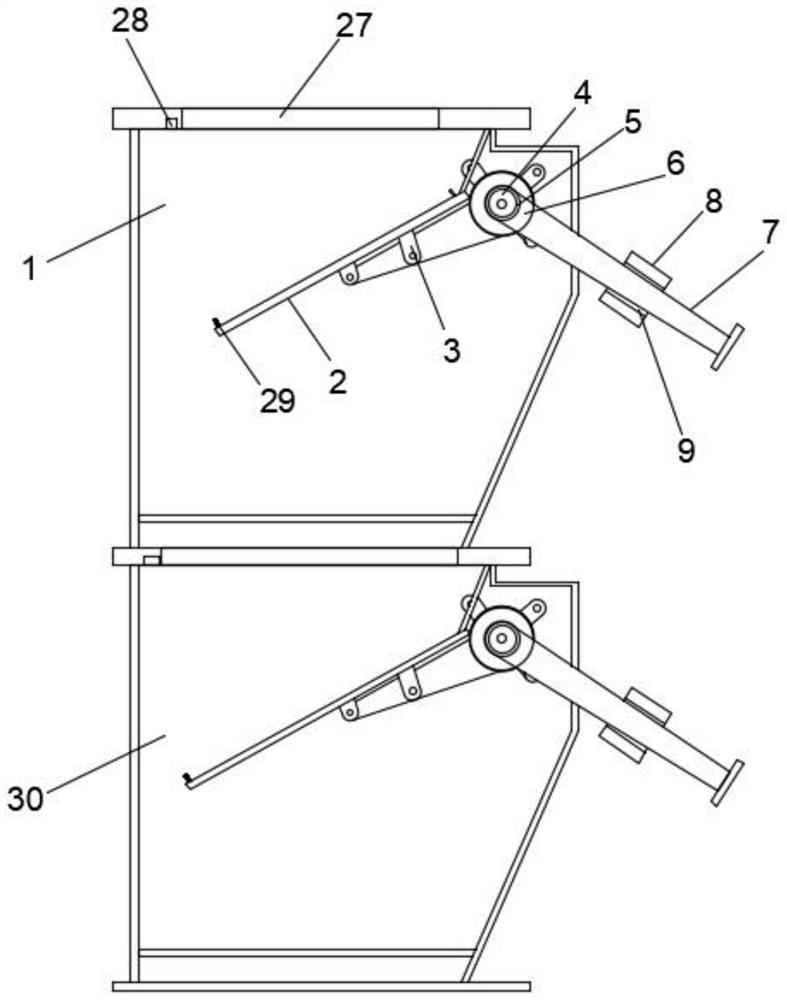

[0029] Such as Figure 1-3 As shown, a gravity air lock valve for boiler dust collection proposed by the present invention includes a first valve body 1, and the inside of the first valve body 1 is fixedly connected with a rotating shaft 4 near the left side, through which the rotating shaft 4 can effectively The bearing 6 and the weight frame 7 are rotated and limited. The outer surface of the rotating shaft 4 is provided with a bearing 6, and the bearing 6 is sleeved on the outer surface of the rotating shaft 4. The outer surface of the rotating shaft 4 is fixedly connected near the front end. There is a weight frame 7, and the weight frame 7 can effectively limit the sliding of the weight 8, and the weight frame 7 has a T-shaped structure, and the outer surface of the weight frame 7 of the T-shaped structure is covered with a weight 8 , using the gravity of the weight 8 to open and close the valve head 2, so that no external motor mechanical power is needed, and the purpose...

Embodiment 2

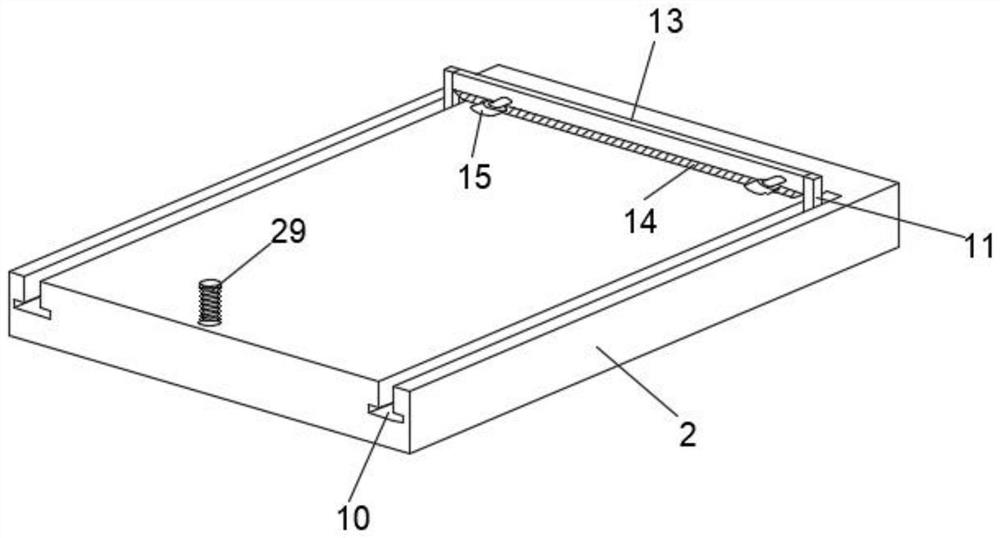

[0033] Such as Figure 1-6 As shown, the outer surface of the upper end of the push rod 3 is fixedly connected with the valve head 2, and the outer surface of the upper end of the valve head 2 is provided with a first chute 10 near both ends, and the first chute 10 is in a T-shaped structure. The inside of the chute 10 is slidably connected with a slider 11, and the slider 11 is also in a T-shaped structure. The first chute 10 of the T-shaped structure and the slider 11 of the T-shaped structure are matched and slid. The first chute 10 and the slider 11 can make the slider 11 effectively slide inside the first chute 10, and will not break away from the first chute 10 when sliding. The outer surface of the upper end of the slider 11 is fixedly connected with a connection rod 13, and the connecting rod 13 is connected with the sliders 11 inside the two first chute 10, the outer surface of the lower end of the connecting rod 13 is fixedly connected with a scraper 14, and the scra...

Embodiment 3

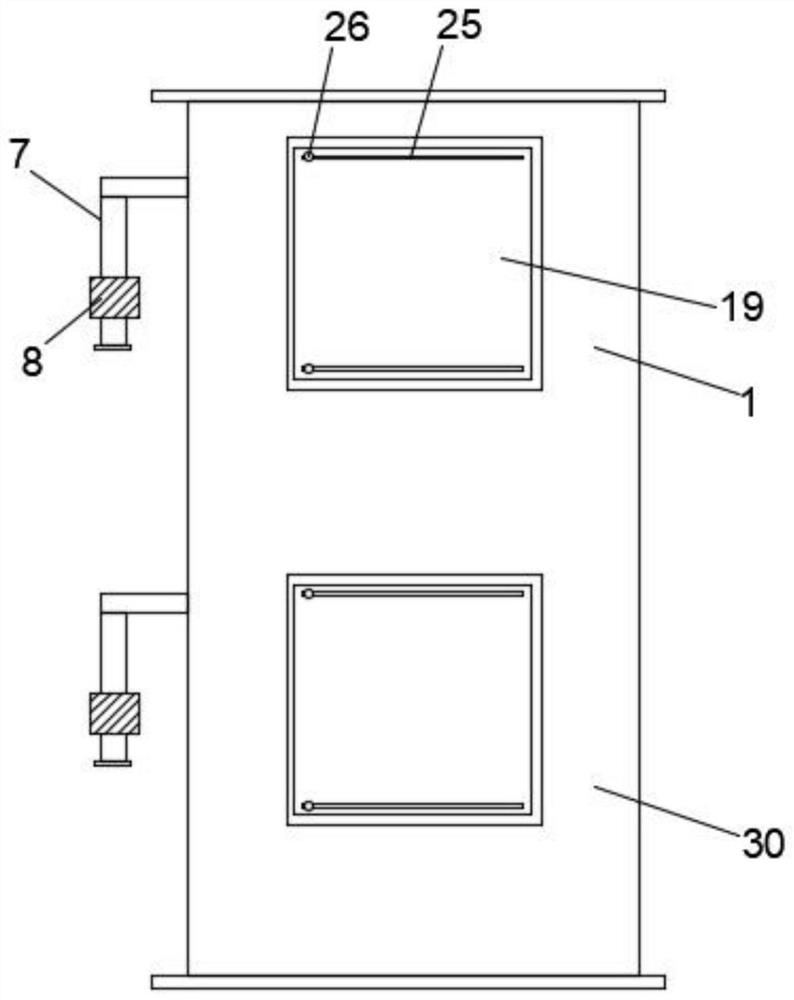

[0038] Such as Figure 2-8 As shown, the right outer surface of the first valve body 1 is provided with an inspection window 19 close to the middle position, the inspection window 19 is fixed to the outer surface of the first valve body 1 by hinges, and the inspection window 19 is opened from left to right, and the inspection window 19 A scraper 20 is provided on the outer surface of the left side, and the inner surface of the maintenance window 19 can be scraped and cleaned by using the scraper 20, which can make it easier to see from the outside to the inside, and is convenient for the staff to check. The right side of the scraper 20 The outer surface of the side is fixedly connected with an L-shaped rod 21 near the upper end and the lower end. The scraper 20 can be effectively driven to move by the L-shaped rod 21. The inside of the inspection window 19 is provided with a through groove 22 near the upper end. The left side of the inspection window 19 The side outer surface ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com