Preparation process and system for raw material used for dry-process sintering production of aluminum oxide clinker

A preparation system and alumina technology, which is applied in the field of dry sintering to produce alumina clinker, can solve the problems of high power consumption of the grinding system, unreasonable particle size distribution, and high production and operation costs, so as to save grinding power consumption and reduce Particle distribution is unreasonable and the effect of solving the increase of maintenance cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

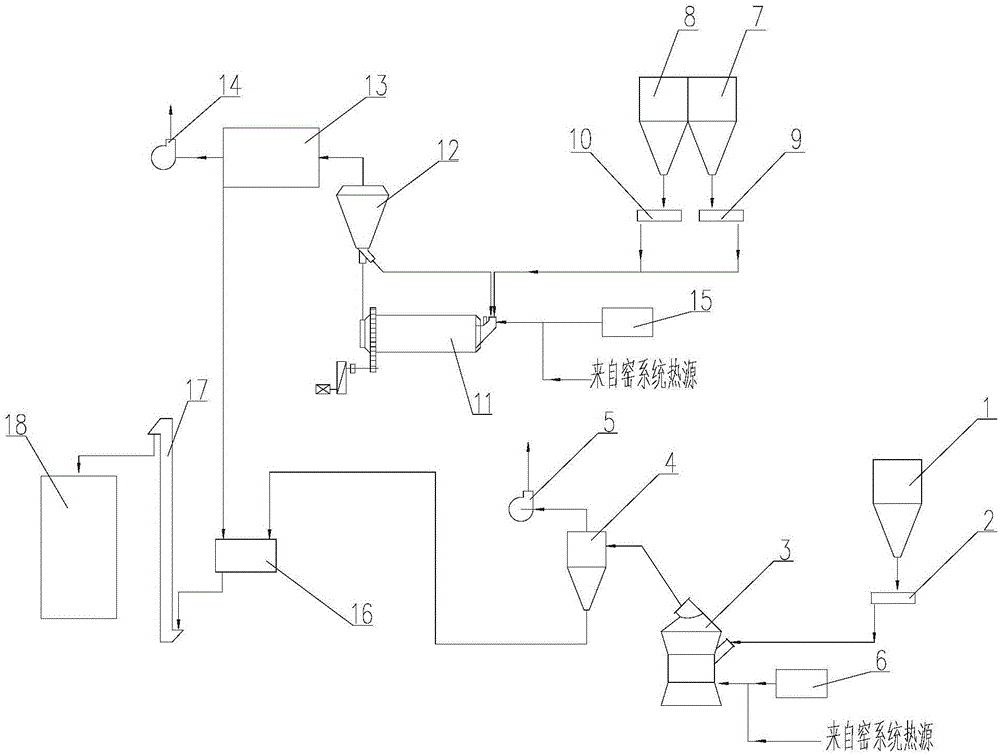

[0021] In order to further understand the invention content, characteristics and effects of the present invention, the following examples are given, and detailed descriptions are as follows in conjunction with the accompanying drawings:

[0022] See figure 1 , a raw material preparation process for the production of alumina clinker by dry sintering. After the limestone is measured according to the proportion, it is sent to the vertical mill 3. After being ground and selected by the vertical mill 3, the qualified limestone powder is sent to the gas-solid Separator Ⅰ4, after being collected by gas-solid separator Ⅰ4, is sent to the mixing device 16; Nepheline and white pulp are sent to the ball mill 11 after proportioning and metering, and are sent to the powder classifier 12 by air for classification after grinding. The graded nepheline and white slurry powder are sent to the gas-solid separator II13 for collection, and then sent to the mixing device 16; the limestone powder, n...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com