Preparation method of raw material for solid waste synergistic complementary preparation of sulphate aluminate cement

A technology for sulfoaluminate cement and raw meal, applied in the field of sulfoaluminate cement, can solve the problems of poor adaptability of ball mills, prolonged feeding time, waste of energy, etc., to reduce system ventilation, save fan power consumption, expand Application-wide effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

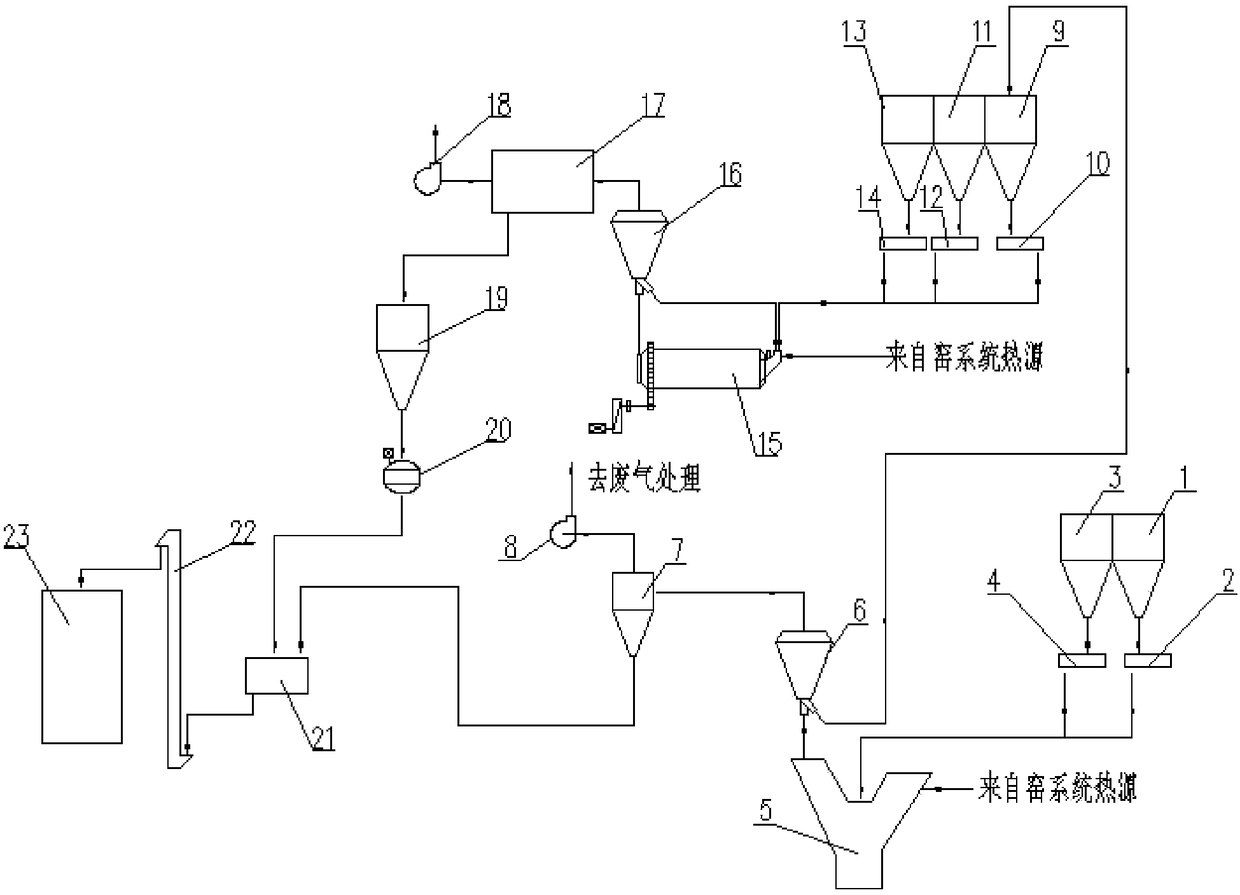

[0037]A raw meal preparation method for solid waste synergistic and complementary preparation of sulphoaluminate cement. The production process system includes a drying system for high-moisture materials such as calcium carbide slag and red mud, and coarse powder in fly ash, aluminum slag and high-moisture materials Particle grinding system and mixing homogenization system.

[0038] The drying system for high-moisture materials such as calcium carbide slag and red mud includes high-moisture material calcium carbide slag bin 1, weighing scale 2, high-moisture material red mud bin 3, weighing scale 4, drying breaker 5, high-efficiency powder separator 6, and cyclone 7. System fan8.

[0039] The mixed grinding system of fly ash, aluminum slag and coarse particles in high-moisture materials includes a storage bin 9 for coarse particles in high-moisture materials, a weighing scale 10, a fly ash bin 11, a weighing scale 12, and an aluminum slag bin 13. Measuring scale 14, ball mill...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com