Power embedment anchor with high-frequency small amplitude vibration

A low-amplitude, high-frequency technology, applied in anchor points, ship parts, transportation and packaging, etc., can solve the problems of high cost and high rocket thrust requirements, and achieve the effects of low cost, simple implementation and reduced pulling force.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

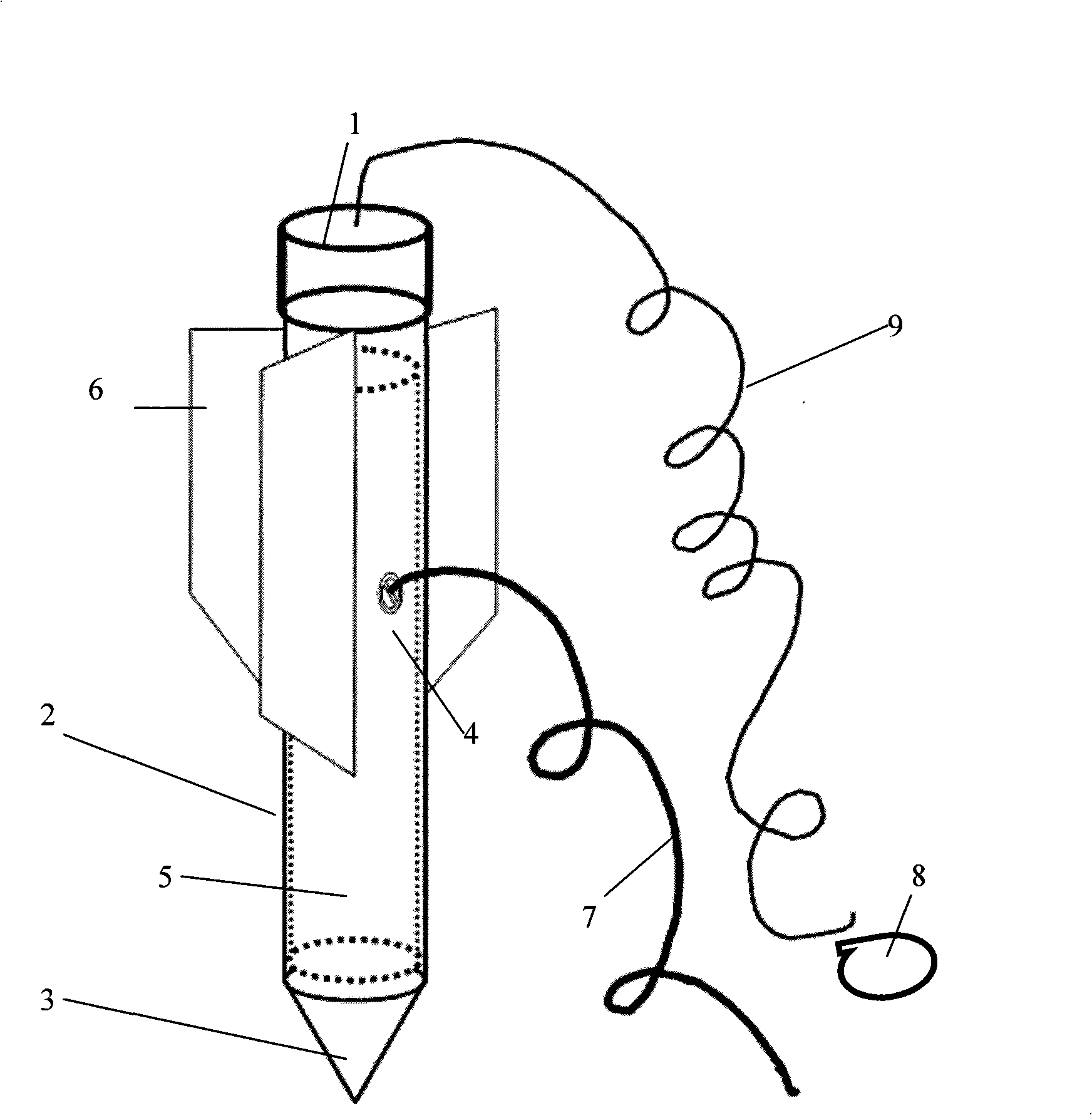

[0022] Example 1: A dynamic embedded anchor with high-frequency micro-amplitude vibration and its working process

[0023] Such as figure 1 As shown, the anchor is composed of anchor cover 1, anchor stem 2, anchor cone 3, lifting lug 4, high-frequency micro-amplitude vibration motor 5, main fin 6, anchor chain 7, power supply 8 and cable 9, and anchor cover 1 is set on The upper part of the anchor shaft 2, the anchor cone 3 is arranged on the lower part of the anchor shaft 2, the lifting lug 4 is arranged on the wall surface of the outer wall of the anchor shaft 2, the anchor chain 7 is connected to the lifting ear 4, and the high-frequency micro-amplitude vibration motor 5 is arranged on the anchor shaft 2 Inside, the main fin 6 is composed of four pieces, which are uniformly and symmetrically arranged on the wall surface of the outer wall of the anchor 2. The power supply 8 provides power for the high-frequency micro-vibration motor 5 through the cable 9, and the cable 9 is ...

Embodiment 2

[0028] Example 2: A dynamic embedded anchor with high-frequency micro-amplitude vibration and its working process

[0029] The anchor consists of an anchor cover 1, an anchor stem 2, an anchor cone 3, lifting lugs 4, a high-frequency micro-vibration motor 5, a main fin 6, an anchor chain 7, a power supply 8 and a cable 9. The anchor cover 1 is set on the anchor stem 2 The anchor vertebra 3 is arranged on the lower part of the anchor trunk 2, the lifting lug 4 is arranged on the wall surface of the outer wall of the anchor trunk 2, the anchor chain 7 is connected to the lifting lug 4, and the high-frequency micro-amplitude vibration motor 5 is arranged inside the anchor trunk 2, The main fin 6 is composed of three pieces, which are evenly and symmetrically arranged on the wall surface of the outer wall of the anchor shaft 2. The power supply 8 provides power for the high-frequency micro-amplitude vibration motor 5 through the cable 9, and the cable 9 is connected to the power su...

Embodiment 3

[0034] Example 3: A dynamic embedded anchor with high-frequency micro-amplitude vibration and its working process

[0035] The anchor consists of an anchor cover 1, an anchor stem 2, an anchor cone 3, lifting lugs 4, a high-frequency micro-vibration motor 5, a main fin 6, an anchor chain 7, a power supply 8 and a cable 9. The anchor cover 1 is set on the anchor stem 2 The anchor vertebra 3 is arranged on the lower part of the anchor trunk 2, the lifting lug 4 is arranged on the wall surface of the outer wall of the anchor trunk 2, the anchor chain 7 is connected to the lifting lug 4, and the high-frequency micro-amplitude vibration motor 5 is arranged inside the anchor trunk 2, The main fin 6 is composed of two pieces, which are evenly and symmetrically arranged on the wall surface of the outer wall of the anchor shaft 2. The power supply 8 provides power for the high-frequency micro-amplitude vibration motor 5 through the cable 9, and the cable 9 is connected to the power supp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com