Fuel compositions and methods thereof

a technology of fuel compositions and compositions, applied in the direction of fuel additives, liquid carbonaceous fuels, petroleum industry, etc., can solve the problems of many octane improving compounds used, other such additives, falling into disfavor, and knocking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

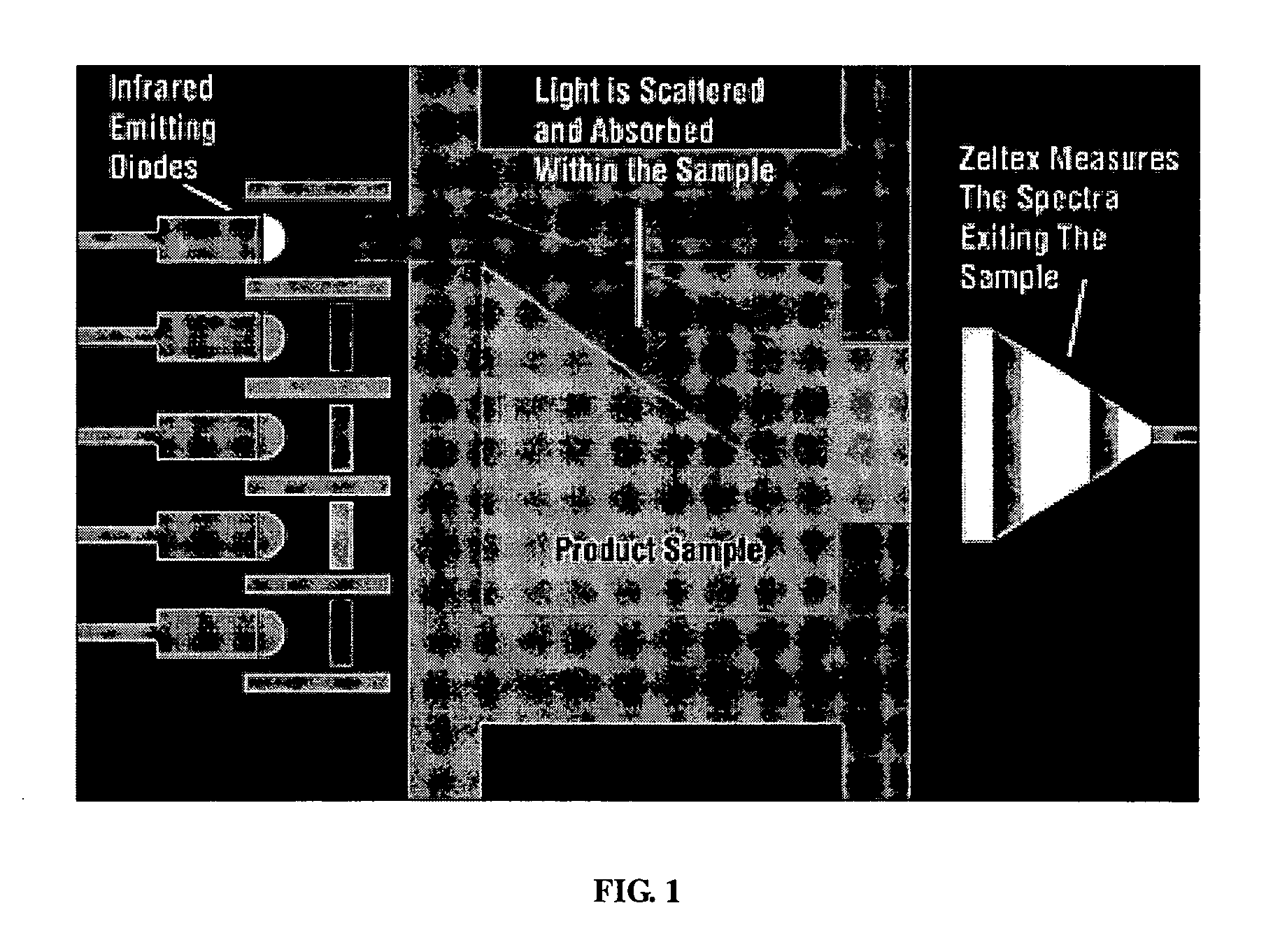

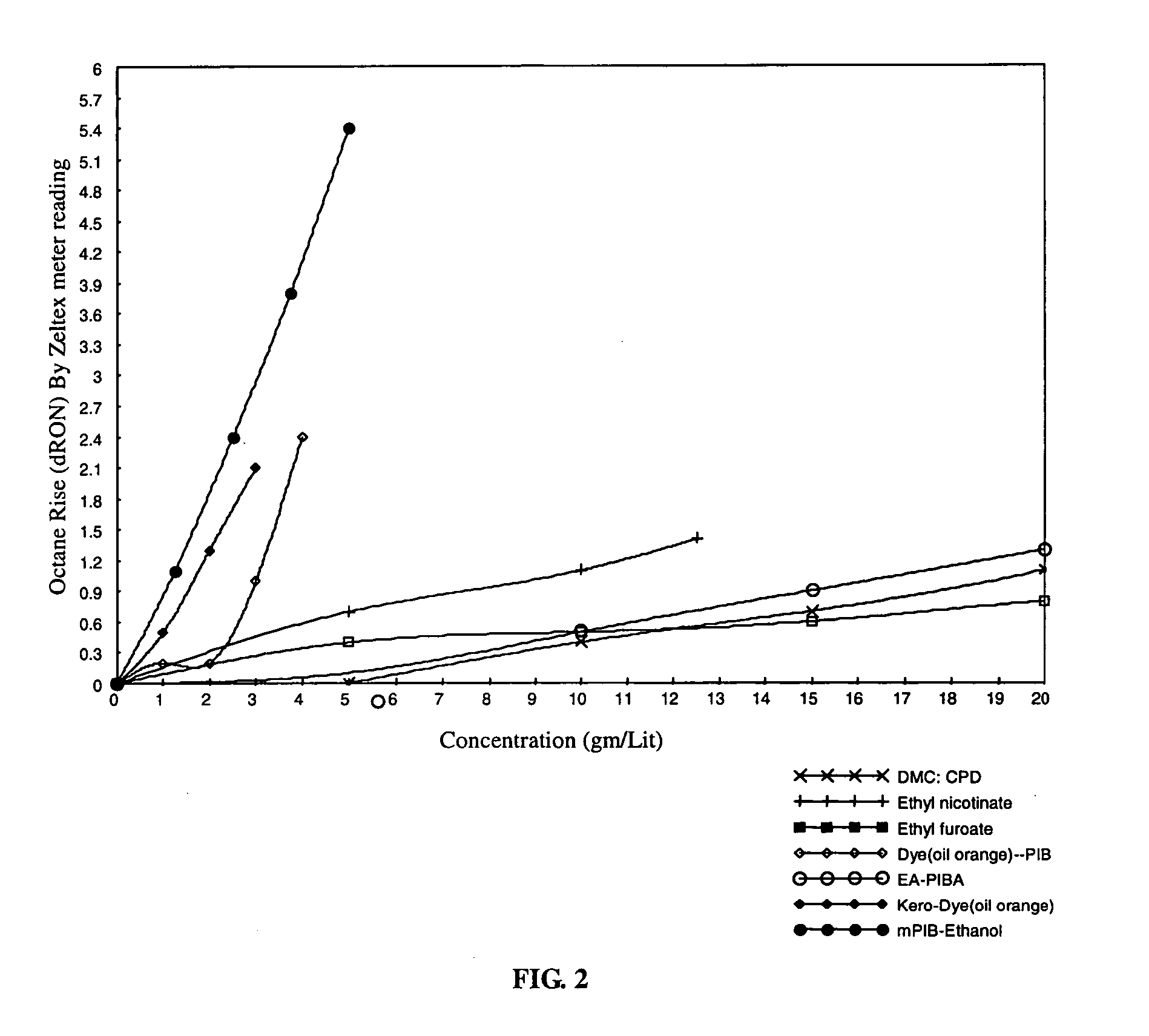

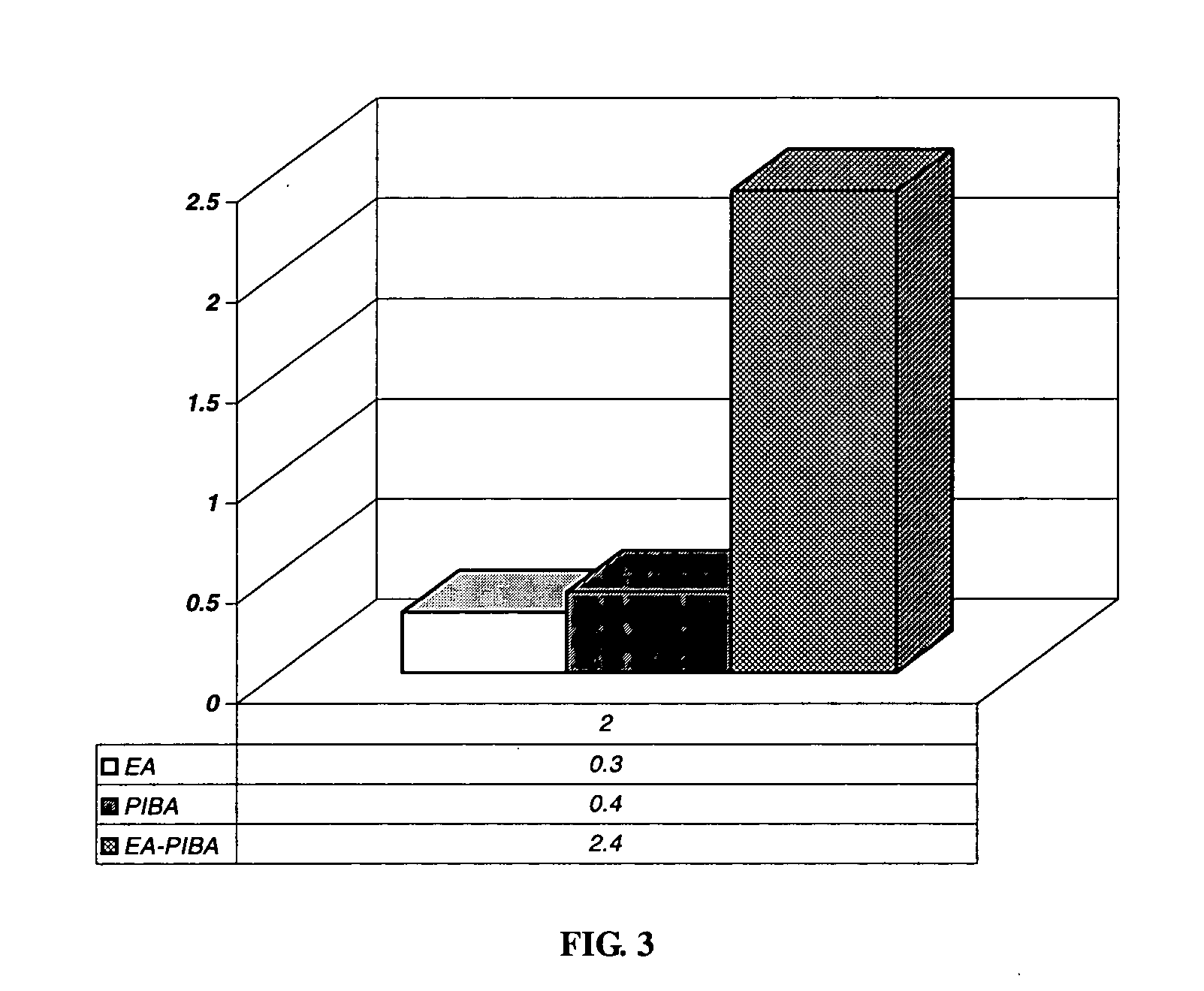

Image

Examples

example 1

[0114] A mixture of 15 gm of oil orange dye, 24.15 gm of polyisobutelene bromide and 100 ml diphenyl ether was refluxed for 8-10 hrs under stirring with elimination of HBr. The reaction monitored by TLC. After completion, reaction mixture was dumped in 200 ml water to remove acidity. Solvent was removed azeotropically and residue is distilled at reduced pressure. The yield of oil orange dye-polyisobutelene-oil orange dye conjugate reaction product was 52%.

example 2

[0115] A mixture of 15 gm of free base of dye (indoine blue), 18.3 gm of Polyisobutelene bromide and 50 ml of diphenyl ether was refluxed for 4 hrs under stirring with elimination of HBr. The reaction monitored by TLC. After completion, the reaction mixture was dumped in water, solvent was removed azeotropically and residue was distilled at reduced pressure. The yield of indoine blue dye-polyisobutelene-indoine blue dye conjugate reaction product was 96%.

example 3

[0116] A mixture of anisic acid (5 gm), 2 ml of concentrated sulphuric acid and 55 ml of absolute ethanol was refluxed at 80° C. for 8 hrs under stirring. The reaction monitored by TLC. After completion, reaction mixture was dumped in cold water and oily layer was separated. The aqueous layer was extracted with dichloromethane. This extracted layer and oily layer were combined and washed with 5% sodium bicarbonate solution to remove unreacted anisic acid. The dichloromethane was removed and residue was distilled at reduced pressure. The yield of ethyl anisate was 86%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com