Fuel injection control method and device of double-fuel internal-combustion engine

A technology of fuel injection and control device, which is applied in the directions of fuel injection device, fuel injection control, low-pressure fuel injection, etc., can solve the problems of increasing the cost of fuel supply device and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

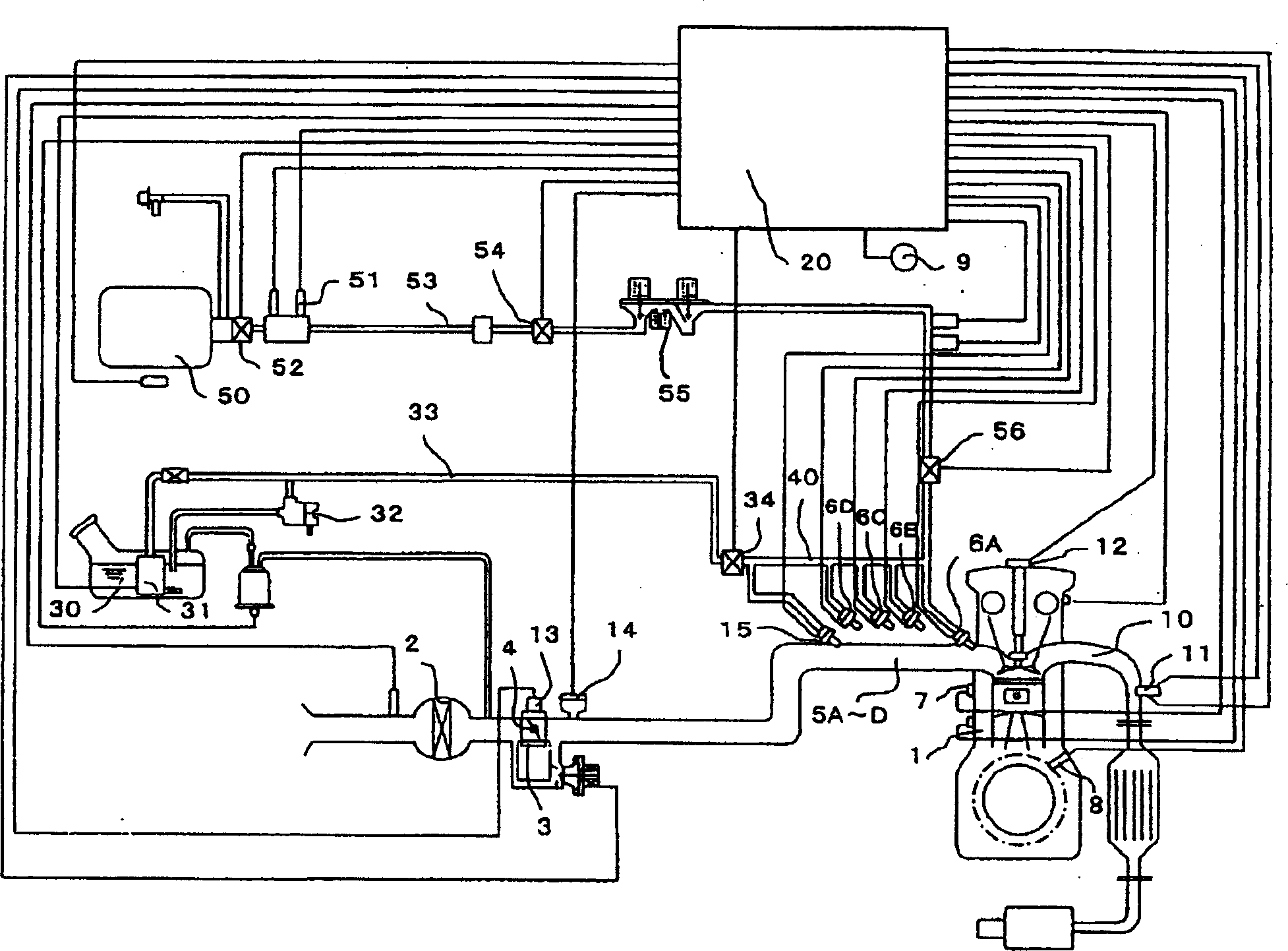

[0018] The embodiments of the present invention will be described below. figure 1 It is a structural diagram of the system to which the present invention is applied.

[0019] figure 1 This is a structural diagram of a system to which the fuel injection device of the present invention is applied. The intake pipes 5A to 5D are provided with gas and liquid fuel injection valves 6A to 6D for injecting fuel. A throttle body 3 is provided upstream of the throttle valve body 3, and a throttle valve 4 is accommodated. In order to detect the load state of the internal combustion engine 1, a throttle valve opening sensor 13 and an intake pipe negative pressure sensor 14 are provided.

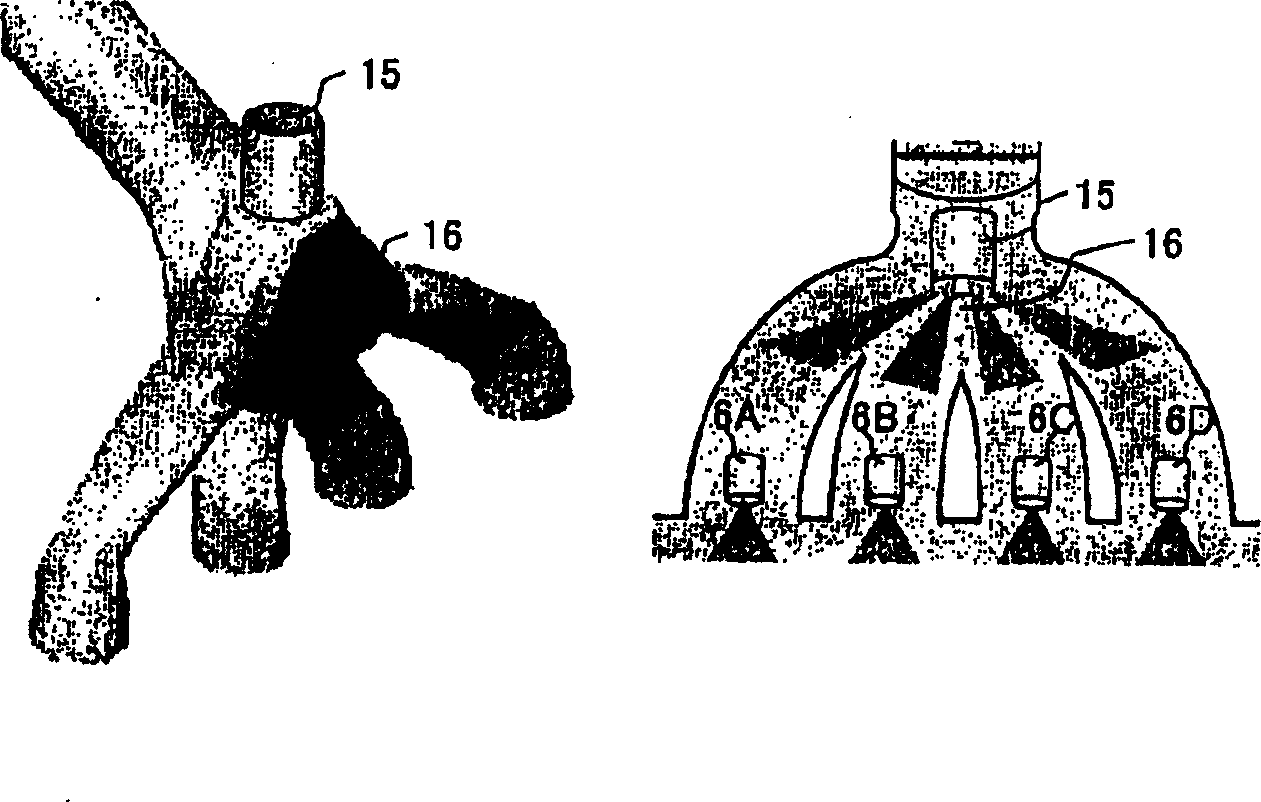

[0020] The gas and liquid fuel injection valves 6A to 6D have a structure in which fuel is introduced from the upper part and injected from the orifice at the tip. The fuel is metered by the orifice provided on the movable valve and the nozzle that are moved up and down by electromagnetic force. injection....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com