Establishment method of blast-furnace injected pulverized coal cost performance evaluation model

A blast furnace coal injection and evaluation model technology, applied in blast furnaces, blast furnace details, furnace types, etc., can solve the problems of large subjective influence, large amount of data, low theoretical level, etc., and achieve the effect of optimal selection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] specific implementation plan

[0037] The above content of the present invention will be further described in detail below in conjunction with the specific implementation manner of specific implementation examples:

[0038] First, establish a cost-effective evaluation model for blast furnace injection coal:

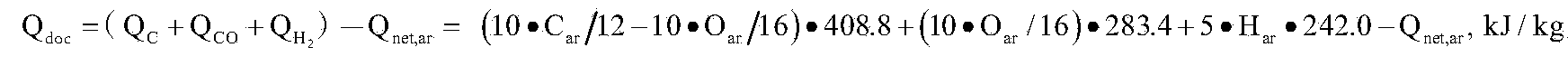

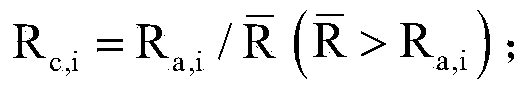

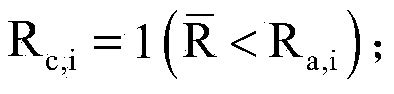

[0039] (1) The cost performance evaluation model of pulverized coal is mainly based on the actual supply heat of pulverized coal (Q e ) and injection cost (P e ) on the two indicators; among them, the pulverized coal actually supplies heat (Q e ) includes 8 sub-indices, namely ash content and composition (A), air-dry basis water content (M ar ), sulfur content (S), relative combustion rate (R c,i ), carbon content (C ar ), oxygen content (O ar ), hydrogen content (H ar ), low calorific value (Q net.ar ); Injection cost (P e ) includes 4 indicators, that is, the incoming coal price (P i ), fluidity (LI), grindability (HGI), external water content (M f ); ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com