Intelligent conditioning system for deep dewatering of sludge

A deep dehydration and sludge technology, applied in the direction of dehydration/drying/concentrated sludge treatment, etc., can solve the problems of heavy odor, insufficient mixing, and inability to mix evenly.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

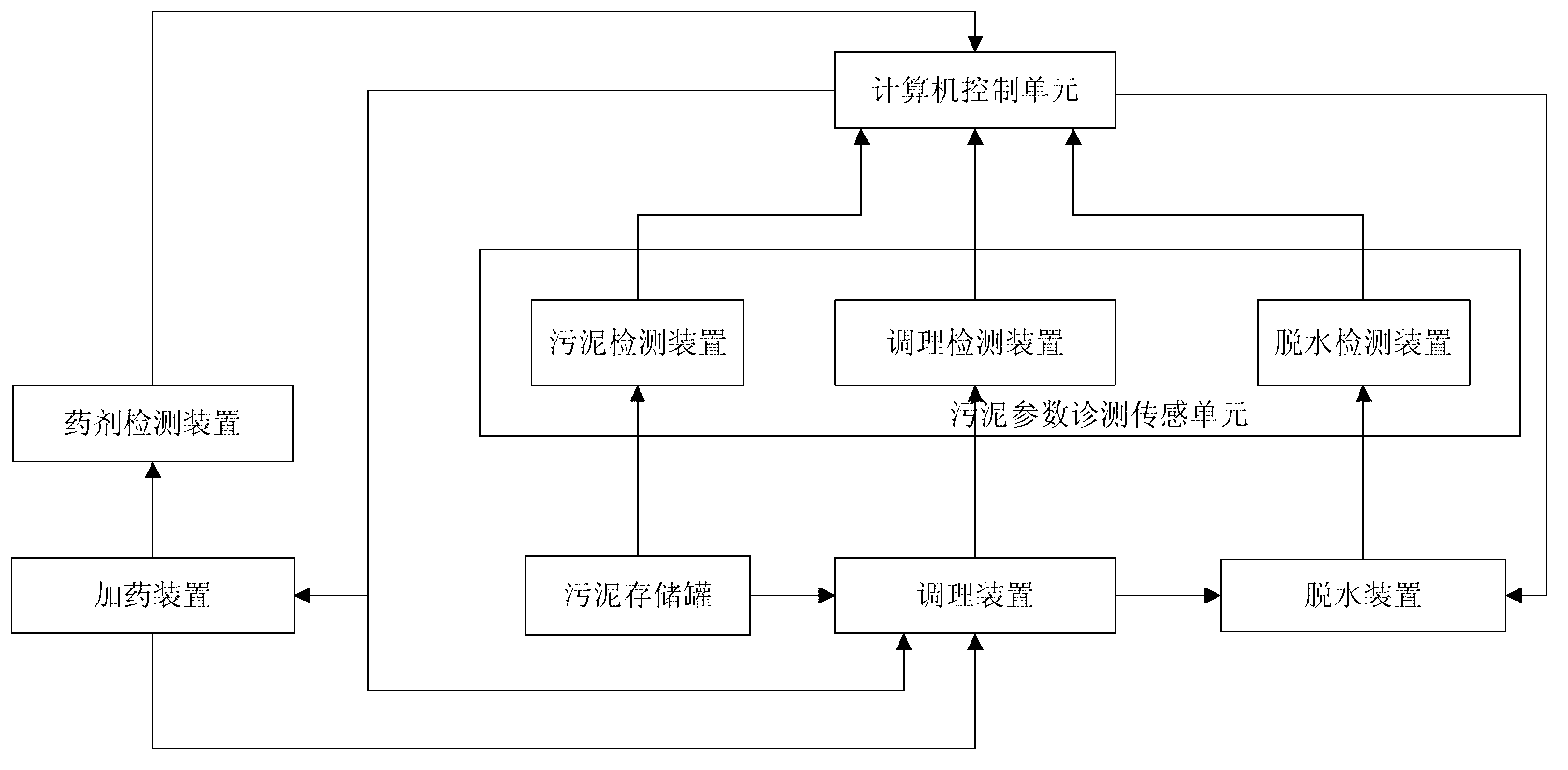

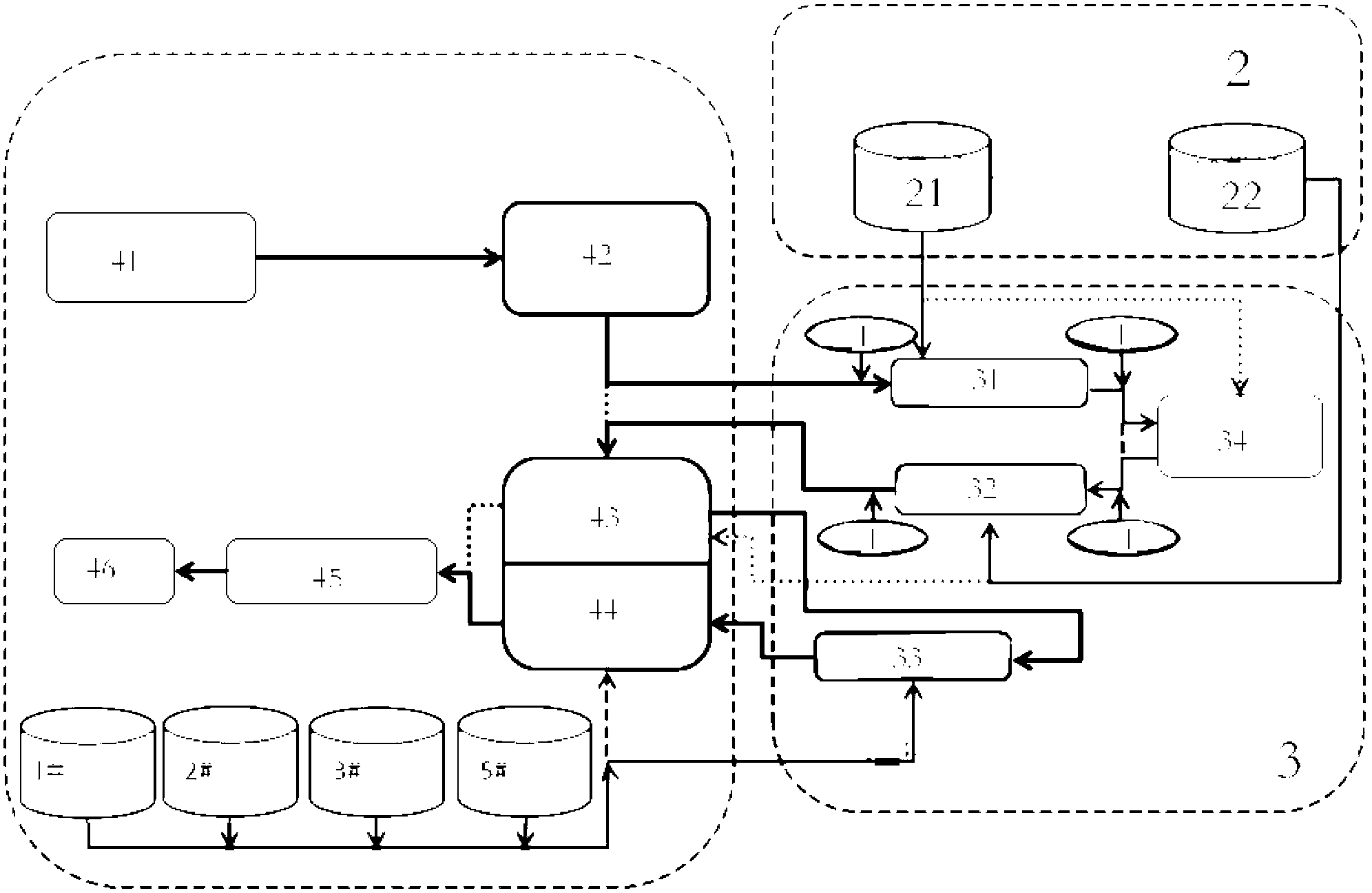

[0020] Such as figure 1 As shown, an intelligent conditioning system for deep dehydration of sludge includes an intelligent diagnosis module, a dosing device and a conditioning device. Through the intelligent diagnosis module, the sludge to be treated can be detected first to determine the time and time of dosing. During the dosing process of the dosing device, the intelligent diagnosis module will constantly detect and feedback the process, so as to adjust the type, dosage and time of dosing in time. Through the three modules of the present invention, the existing The efficiency of the sludge dewatering process in the technology has been greatly improved, reducing the water content of the traditionally treated sludge from 70-99% to below 60%, and the output weight of the final sludge is reduced by more than 50%, while still maintaining the original organic calorific value More than 70%, that is, about 600-3000 kcal / kg, for further incineration and drying treatment.

[0021] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com