Novel waterproof compound coal binder

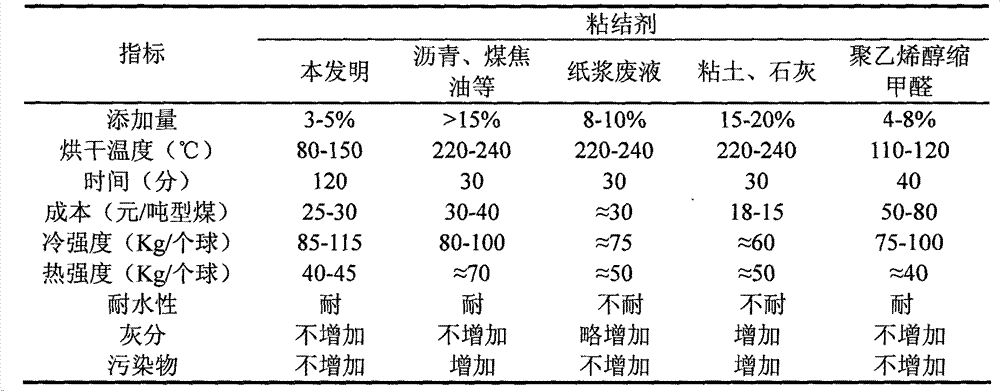

A binder and composite technology, which is applied in the field of new waterproof composite coal binder, can solve the problems of increased cost of cooking hemp waste liquid, limited sources of raw materials, complicated manufacturing process, etc., and achieves convenient and cheap material sources, The effect of reducing secondary pollution and simple production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] Dissolve 1.0 g of sodium carboxymethyl cellulose in 10 ml of water, and keep stirring (pay attention to avoid shear force stirring). Then 3.3 grams of bentonite, 0.3 grams of cornstarch, 0.16 grams of thermoplastic phenolic resin and 3.64 grams of sulfur-aluminum cement were evenly mixed and 200 grams of anthracite powder with a particle size of less than 3 mm were added and mixed evenly, and then the prepared sodium carboxymethyl cellulose Add and stir evenly, the total amount of binder added is 4% of the coal powder, and finally at 100-200Kg / cm 2 Molded into ellipsoidal briquettes at room temperature under pressure.

[0019] The formed briquettes are placed in the drying kiln for drying after two days. The temperature at the entrance of the kiln is 80°C, and then slowly rises to 150°C. This process is kept for 2 hours, and the briquettes are produced, and the cold strength is greater than 90 kg / Each ball, with a heat strength of 45 kg / ball, placed in water for conti...

Embodiment 2

[0021] Put 1.0 g of powdered sodium carboxymethylcellulose into 10 ml of water to dissolve, and keep stirring (note avoiding shear force stirring). Then 2.8 grams of bentonite, 0.3 grams of cornstarch, 0.16 grams of thermoplastic phenolic resin and 4.14 grams of aluminate cement were evenly mixed, and 200 grams of anthracite coal powder with a particle size of less than 3 mm were added and mixed evenly, and then the prepared carboxymethyl cellulose Sodium is added and stirred evenly, the total amount of binder added is 4% of the coal powder, and finally at 100-200Kg / cm 2 Molded into ellipsoidal briquettes at room temperature under pressure.

[0022] The formed briquettes are placed in the drying kiln for drying after two days. The temperature at the entrance of the kiln is 80°C, and then slowly rises to 150°C. This process is kept for 2 hours, and the briquettes are produced, and the cold strength is greater than 90 kg / Each ball, with a heat strength of 45 kg / ball, placed in...

Embodiment 3

[0024] Put 0.6 grams of powdered polyvinyl alcohol into 10 milliliters of water to dissolve, and keep stirring (note avoiding shear force stirring). Then 3.3 grams of bentonite, 0.3 grams of tapioca starch, 0.16 grams of thermoplastic phenolic resin, and 3.64 grams of sulfur-aluminum cement were evenly mixed, and 200 grams of anthracite coal powder with a particle size of less than 3 mm were added to mix evenly, and then the prepared polyvinyl alcohol was added and stirred Evenly, the total amount of binder added is 4% of the coal powder, and the final amount is 100-200Kg / cm 2 Molded into ellipsoidal briquettes at room temperature under pressure.

[0025] The formed briquettes are placed in the drying kiln for drying after two days. The temperature at the entrance of the kiln is 80°C, and then slowly rises to 150°C. This process is kept for 2 hours, and the briquettes are produced, and the cold strength is greater than 90 kg / Each ball, with a heat strength of 45 kg / ball, pla...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thermal stability | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com