A kind of composite biomass briquette binder and its preparation method and application

A biomass and composite technology, used in waste fuel, petroleum industry, solid fuel, etc., can solve the problems of low high temperature thermal strength, low coal cooling strength, poor thermal stability, etc., to achieve high tar yield and improve cold strength. , the effect of improving thermal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

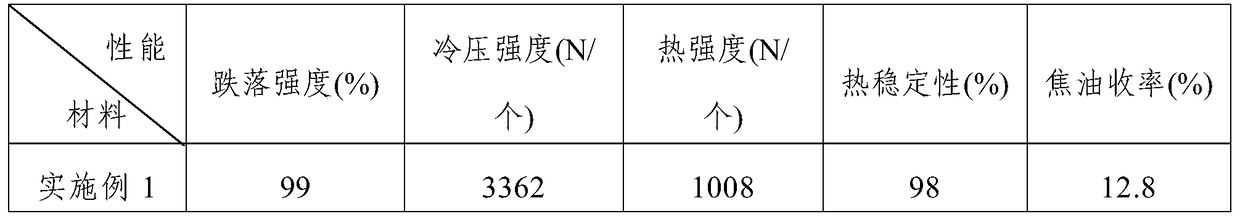

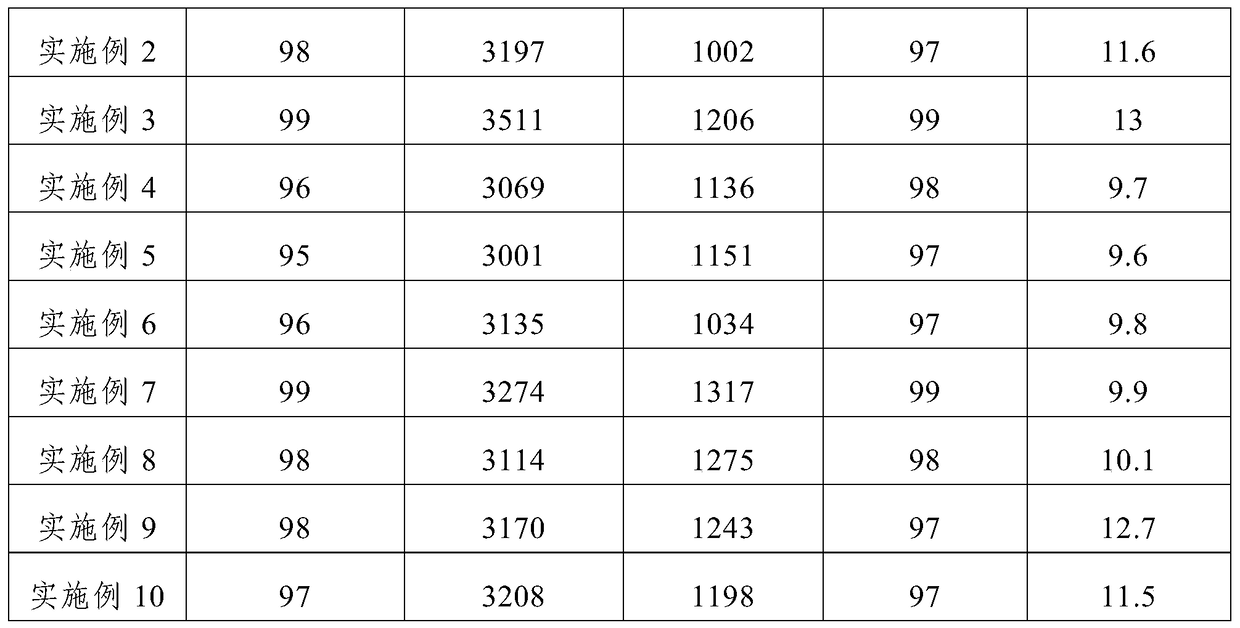

Examples

Embodiment 1

[0029] The composite biomass briquette binder of this embodiment is made of the following raw materials in parts by weight: 1 part of sunflower stalks, 15 parts of sodium hydroxide solution, 0.35 parts of bentonite, and 1.5 parts of emulsified asphalt; the mass of the sodium hydroxide solution The concentration is 1%, and the sunflower stalks are dried and pulverized sunflower stalks.

[0030] The preparation method of the compound type biomass briquette binder of the present embodiment comprises the following steps:

[0031] Step 1, drying and pulverizing the sunflower stalks, mixing the sodium hydroxide solution with the pulverized sunflower stalks, hydrolyzing the pulverized sunflower stalks under stirring conditions, and obtaining modified sunflower stalks after filtering; the modified sunflower stalks The mass content of water in the straw is 75%; the temperature of the hydrolysis treatment is 90° C., the time is 3 hours, and the average particle diameter of the pulverize...

Embodiment 2

[0037] The composite biomass briquette binder of this embodiment is made of the following raw materials in parts by weight: 1 part of sunflower straw, 20 parts of sodium hydroxide solution, 0.3 part of bentonite, and 1 part of emulsified asphalt; the mass of the sodium hydroxide solution The concentration is 1.5%, and the sunflower stalks are dried and pulverized sunflower stalks.

[0038] The preparation method of the compound type biomass briquette binder of the present embodiment comprises the following steps:

[0039] Step 1, drying and pulverizing the sunflower stalks, mixing the sodium hydroxide solution with the pulverized sunflower stalks, hydrolyzing the pulverized sunflower stalks under stirring conditions, and obtaining modified sunflower stalks after filtering; the modified sunflower stalks The mass content of water in the straw is 80%; the temperature of the hydrolysis treatment is 95°C, the time is 1.5h, and the average particle size of the pulverized sunflower s...

Embodiment 3

[0045] The composite biomass briquette binder of this embodiment is made of the following raw materials in parts by weight: 1 part of sunflower straw, 10 parts of sodium hydroxide solution, 0.4 part of bentonite, and 2 parts of emulsified asphalt; the mass of the sodium hydroxide solution The concentration is 2%, and the sunflower stalks are dried and pulverized sunflower stalks.

[0046] The preparation method of the compound type biomass briquette binder of the present embodiment comprises the following steps:

[0047] Step 1, drying and pulverizing the sunflower stalks, mixing the sodium hydroxide solution with the pulverized sunflower stalks, hydrolyzing the pulverized sunflower stalks under stirring conditions, and obtaining modified sunflower stalks after filtering; the modified sunflower stalks The mass content of water in the straw is 65%; the temperature of the hydrolysis treatment is 80° C., the time is 4 hours, and the average particle diameter of the pulverized sun...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| drop strength | aaaaa | aaaaa |

| thermal stability | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com