Method for preparing briquette binder

A binder and briquette technology, applied in the field of coal chemical industry, can solve problems such as low viscosity and poor strength, and achieve high catalytic activity, high cold and hot strength, and obvious advantages

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

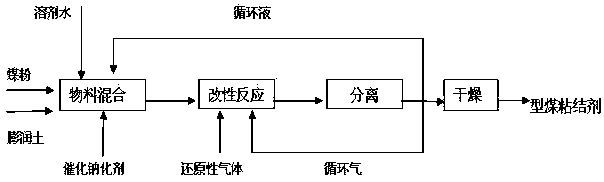

Method used

Image

Examples

Embodiment 1

[0044] In Example 1, a coal modification test was carried out using Xinjiang Heishan long-flame coal as a raw material.

[0045] 40g of 100-mesh pulverized coal, 15g of 100-mesh bentonite, 30g of urban waste water and catalyst Na 2 O 2g, mixed in a high-pressure reactor, fed a reducing gas mixture, wherein the CO content is 50%, the gas is purged and the initial pressure is set to 3MPa, and heated to a reaction temperature of 330°C at a speed of 15°C / min , reacted for 30min, and controlled the pressure in the kettle to reach 20MPa. After the reaction is finished, the reactor is cooled to room temperature, and the reaction materials are taken out, and the water and the coal materials are centrifuged with a 100-mesh filter, and the separated solids are briquette binders.

[0046] Use a caking index tester to measure the briquette binder according to GB / T 5447-1997. The caking index of the product is 85. The swelling value of the product is 8ml / 3g measured by the ammonium chlori...

Embodiment 2

[0048] In Example 2 of the present invention, a coal modification test was carried out using lignite II as a raw material.

[0049] With 200 mesh coal powder 45g, 100 mesh bentonite 5g, urban waste water 40g and catalyst Na 2 CO 3 1.5g, mixed in a high-pressure reactor, fed a reducing gas mixture, the CO content of which was 60%, the gas was purged and the initial pressure was set to 4MPa, heated to a reaction temperature of 340°C at a rate of 15°C / min , reacted for 60min, and controlled the pressure in the kettle to reach 25MPa. After the reaction is finished, the reactor is cooled to room temperature, and the reaction materials are taken out, and the water and the coal materials are centrifuged with a 100-mesh filter, and the separated solids are briquette binders.

[0050] Use a caking index tester to measure the briquette binder according to GB / T 5447-1997, the caking index of the product is 90, the swelling value of the product is 6ml / 3g measured by the ammonium chlor...

Embodiment 3

[0052] In Example 3 of the present invention, a coal modification test was carried out using lignite III as a raw material.

[0053] Put 50g of 200-mesh pulverized coal, 5g of 100-mesh bentonite, 45g of municipal waste water and 2g of catalyst NaOH in a high-pressure reaction kettle and mix them in a high-pressure reactor, and feed a reducing mixed gas, in which the CO content is 80%, and the gas is purged and its initial pressure is set. to 4MPa, heated to a reaction temperature of 340°C at a rate of 15°C / min, reacted for 40min, and controlled the pressure inside the kettle to reach 35MPa. After the reaction is finished, the reactor is cooled to room temperature, and the reaction materials are taken out, and the water and the coal materials are centrifuged with a 100-mesh filter, and the separated solids are briquette binders.

[0054] The briquette binder is measured by a caking index tester according to GB / T 5447-1997, the caking index of the product is 96, the swelling...

PUM

| Property | Measurement | Unit |

|---|---|---|

| cohesion index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com