Oxidation-esterification-grafting three element complex denatured starch and its preparation method and application

A technology of modified starch and ternary compounding, which is applied in the directions of starch derivative coatings, starch derivative adhesives, adhesive types, etc., to achieve the effects of scientific process design, excellent product performance, and easy popularization and application.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

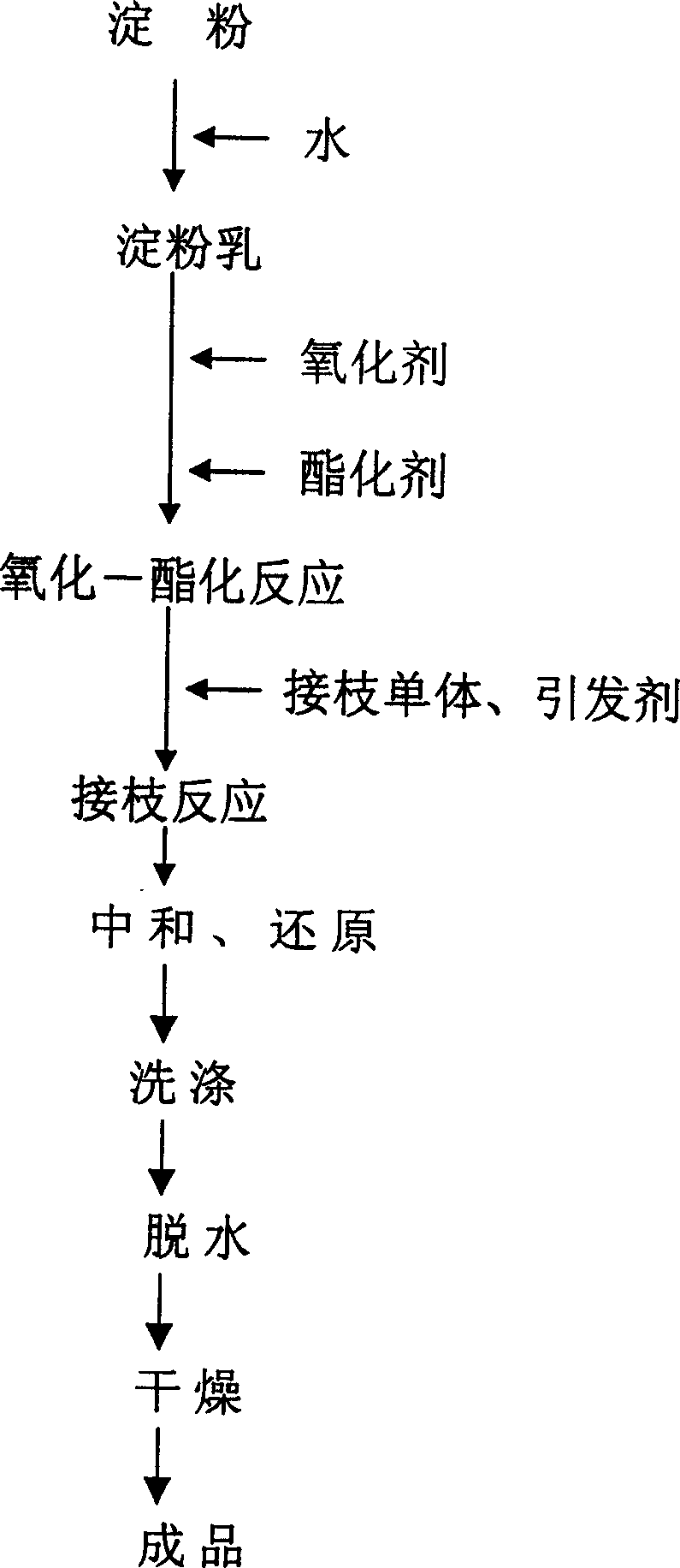

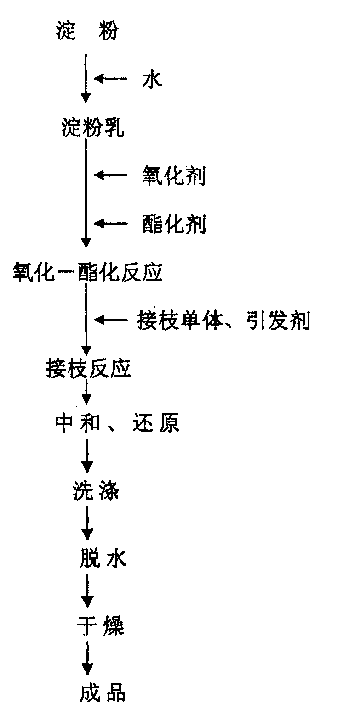

Method used

Image

Examples

Embodiment 1

[0022] Add 1000g of starch with water to adjust the slurry to a concentration of 40% (dry basis), keep stirring, control the temperature at 35°C, adjust the pH to 8.0-9.0 with 3% sodium hydroxide solution, add 200g of sodium hypochlorite dropwise, add sodium hypochlorite dropwise for 30min, drop Add 30g of vinyl acetate, dropwise for 30min, stir for 3h after the dropwise addition, add 30g of acrylamide, 5g of potassium persulfate, stir for 1-2h, reduce with 10% sodium bisulfite, and use 5% hydrochloric acid Neutralized to neutral, washed, dehydrated and dried to obtain finished products.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com