Nano composite biological degradation plastic and preparing method thereof

A biodegradable plastic and nano-composite technology, applied in the field of nano-composite biodegradable plastics and its preparation, can solve the problems of high PLA production cost, slow polymer degradation rate, complex production process, etc., and achieve excellent mechanical properties and heat release speed Effects of retardation and increase in melt fluidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

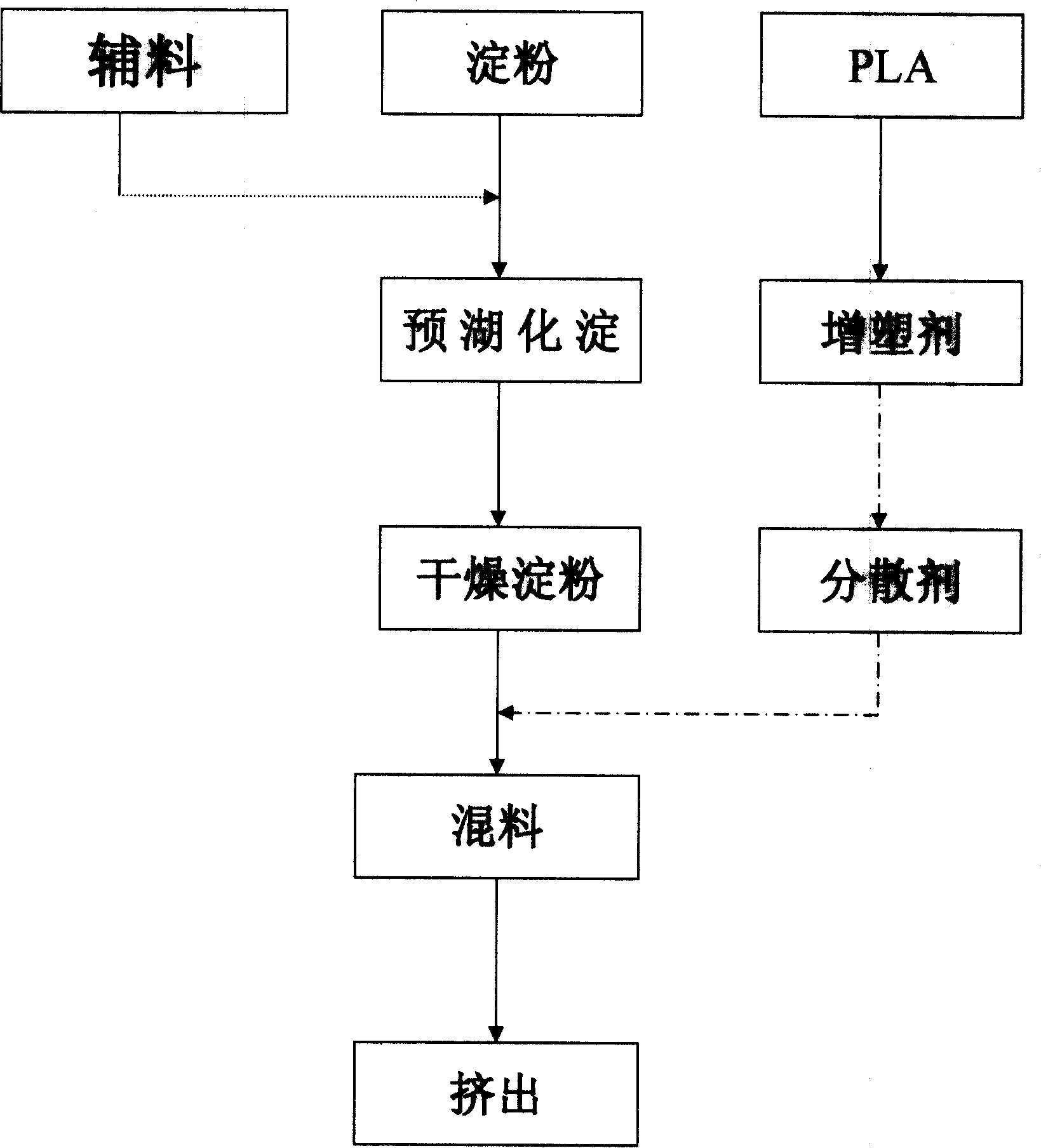

Method used

Image

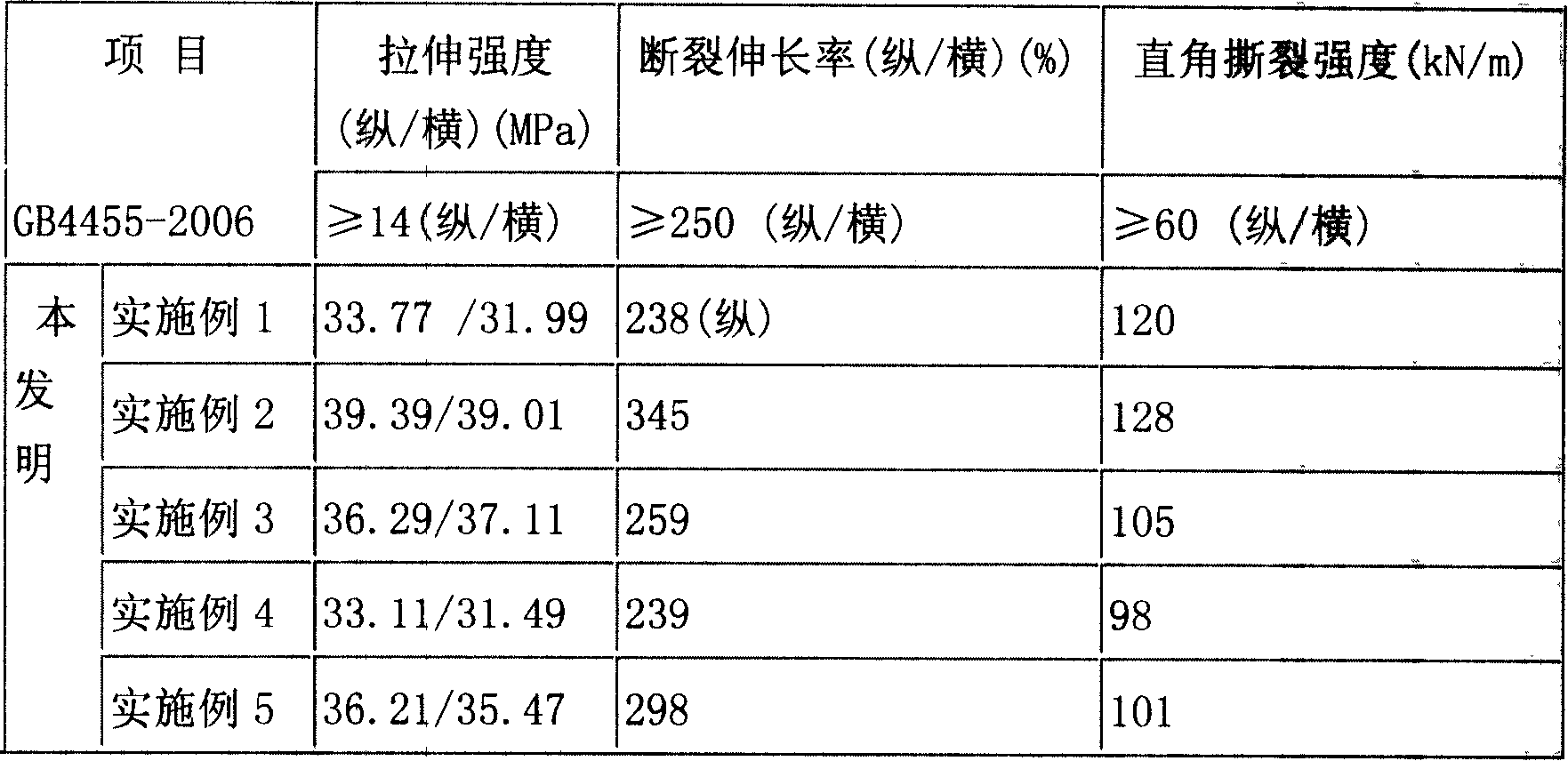

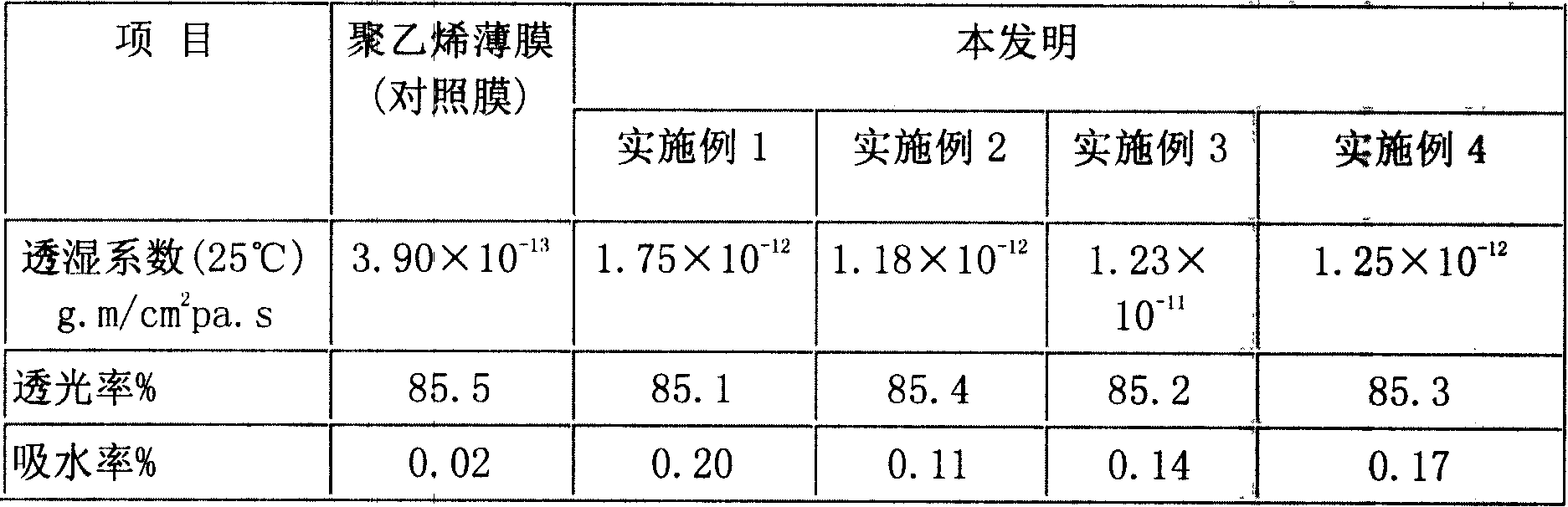

Examples

Embodiment 1

[0040] After mixing 1000 g of starch, 1 g of polyethylene glycol and 5 g of glycerin, extrude through a single-screw extruder at 120° C. and dry to obtain pregelatinized modified starch.

[0041] Disperse 200g of nano-montmorillonite with water that can wet it, add 700g of pre-gelatinized modified starch starch, 600g of PLA, stir and mix at high speed for 30 minutes, dry, and use a single-screw extruder at 130-140-160 Extrude and granulate at ℃.

[0042] It can also be directly formed into a film by blow molding after being extruded from a single-screw extruder. The membrane has a folded diameter of 50 cm.

Embodiment 2

[0044] After mixing 1000 g of starch, 10 g of polyethylene glycol and 0.1 g of glycerin, extruding through a single-screw extruder at 110° C. and drying to obtain pregelatinized modified starch.

[0045] Disperse 400g of nano-montmorillonite with water capable of wetting it (about 60g of water), add 300g of pregelatinized modified starch starch, 400g of PLA, 25g of plasticizer, stir and mix at high speed for 40 minutes, and after drying, use a single The screw extruder is extruded at 140°C, and the film is formed by blow molding process. The membrane has a folded diameter of 150 cm.

Embodiment 3

[0047] After mixing 1000g of starch, 5g of polyethylene glycol and 3g of glycerin, extruding through a single-screw extruder at 100°C and drying to obtain pregelatinized modified starch.

[0048] Disperse 300g of nano-montmorillonite with water capable of wetting it, add 500g of pre-gelatinized modified starch starch, 500g of PLA, and 55g of plasticizer, stir and mix at high speed for 20 minutes, dry, and then use a single-screw extruder 130 Extrude at ℃, granulate; or use blow molding process to form a film. The membrane has a folded diameter of 100 cm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com