Wood-residue fiber foamed cushion packaging material and preparation method thereof

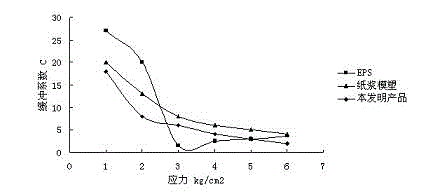

A cushioning packaging and residue technology, applied in the field of cushioning packaging materials and their preparation, can solve the problems of complex production process, poor compression recovery, high cost, etc., and achieve the effects of low overall cost, simple manufacturing process, and short production cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] The birch fiber passing through the 65 mesh sieve was treated with a 2% NaOH solution for 20 hours and then washed to neutrality, put into an oven and dried until the water content was about 3%, and cooled for later use; prepare a starch solution with a solid weight of 40% in Pre-gelatinize in a constant temperature water bath at 62°C and cool for later use; prepare a polyvinyl alcohol solution with a mass fraction of 10%, treat it in a constant temperature water bath at 93°C, and cool it for later use; prepare a borax solution with a mass fraction of 5%, and place it in a constant temperature water bath Dissolve in the pot at 93°C and cool down for later use. By weight, 32 parts of birch fiber, 24 parts of pregelatinized starch and 12 parts of polyvinyl alcohol (PVA) were mixed to prepare a compound adhesive, and azodicarbonamide (C 2 H4O 2 N 4 ) 5 parts as foaming agent, 1 part of zinc oxide (ZnO) as activator, talcum powder (Mg 3 [Si 4 o 10 ](OH) 2 ) 5 parts as...

Embodiment 2

[0025] The larch wood fibers passed through a 75-mesh sieve were treated with 4% NaOH solution for 12 hours, washed to neutrality, dried in an oven until the moisture content was about 5%, and cooled for later use; a starch solution with a solid weight of 48% was prepared in a constant temperature water bath Pre-gelatinize in a pot at 64°C, cool for later use; prepare a 14% polyvinyl alcohol solution, process it in a 95°C constant temperature water bath, and cool it for later use; prepare a 5% borax solution, dissolve it in a constant temperature water bath at 95°C, Let cool and set aside. Weigh 34 parts of larch wood fiber, 28 parts of pregelatinized starch and 10 parts of polyvinyl alcohol (PVA) to prepare a compound adhesive, use 4 parts of p-toluenesulfonyl hydrazide as foaming agent, and 2 parts of sodium stearate 10 parts of calcium carbonate as nucleating agent, 15 parts of VAE emulsion as plasticizer, titanium dioxide (TiO 2 ) 1 part is whitening agent, 5-10 parts of ...

Embodiment 3

[0027] Treat the oak fiber that has passed through a 70-mesh sieve with 5% NaOH solution for 24 hours, then wash it to neutral, put it in an oven and dry it until the moisture content is about 5%, and cool it for later use; prepare a starch solution with a solid weight of 32% in a constant temperature water bath Pre-gelatinize in the pot at 60°C, cool it for later use; prepare 9% polyvinyl alcohol solution, process it in a 95°C constant temperature water bath, and cool it for later use; prepare a 5% borax solution, dissolve it in a constant temperature water bath at 95°C, Let cool and set aside. Weigh 31 parts of oak wood fiber, 21 parts of pregelatinized starch and 12 parts of polyvinyl alcohol (PVA) to prepare a compound adhesive, use 6 parts of sodium bicarbonate as foaming agent, and 3 parts of magnesium stearate as activation agent. A total of 9 parts of silicon dioxide and talcum powder are used as nucleating agents, and a total of 11 parts of glycerol and VAE emulsion m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com