Fragrant and sweet taste cigarette tipping paper production method

A production method and technology of tipping paper, which are applied in the directions of paper, papermaking, paper coating, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] A kind of preparation method of tipping paper for fragrant and sweet flavor cigarette according to the present invention specifically comprises the following steps:

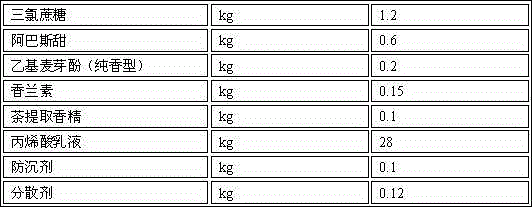

[0014] 1. Production of fragrant and sweet ink. The selected raw materials are: sucralose, aspartame, ethyl maltol (pure flavor type), vanillin, tea extract essence, acrylic emulsion, alcohol, anti-sedimentation agent, dispersant, the weight ratio of each raw material is as follows: As shown in the table below:

[0015]

[0016] Disperse the above raw materials on a slow speed disperser. Mix the acrylic emulsion and alcohol thoroughly first, then add sucralose and aspartame in sequence, and stir for 15 minutes; Lansu and tea extract essence were stirred for 10 minutes, sealed and stored.

[0017] 2. Print on a gravure printing machine, follow the conventional tipping paper process, add a color sequence at the end, and coat the surface of the tipping paper with sweet and fragrant ink. The printing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com