Black currant jam for bread with long shelf life and preparation method thereof

A shelf life and bread technology, which is applied in food preparation, application, food science, etc., can solve problems affecting fermentation, bread embryo moisture migration, bread deformation, etc., so as to avoid the influence of growth cycle and seasonal changes, enhance water-locking performance, The effect of low water activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

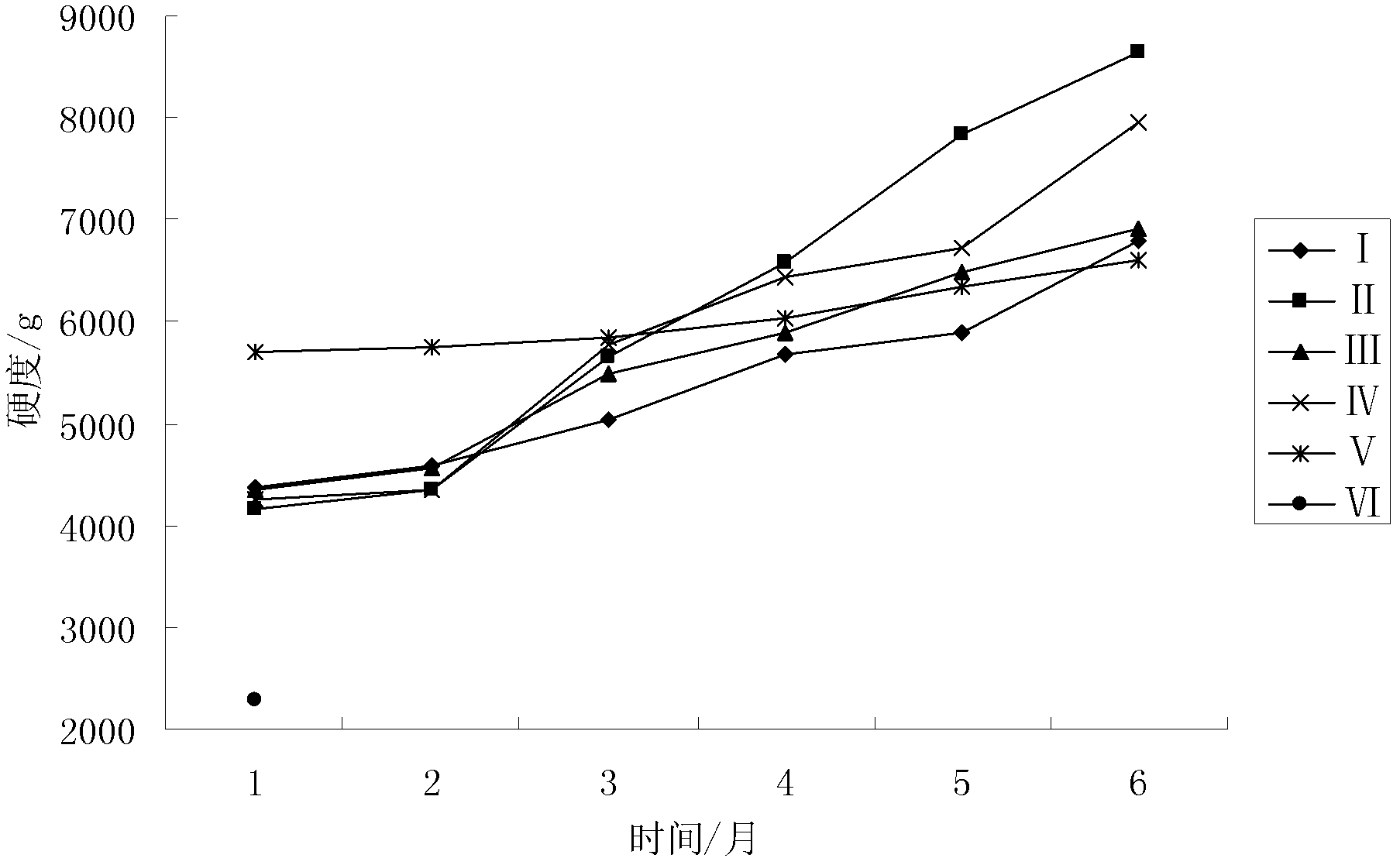

Image

Examples

Embodiment 1

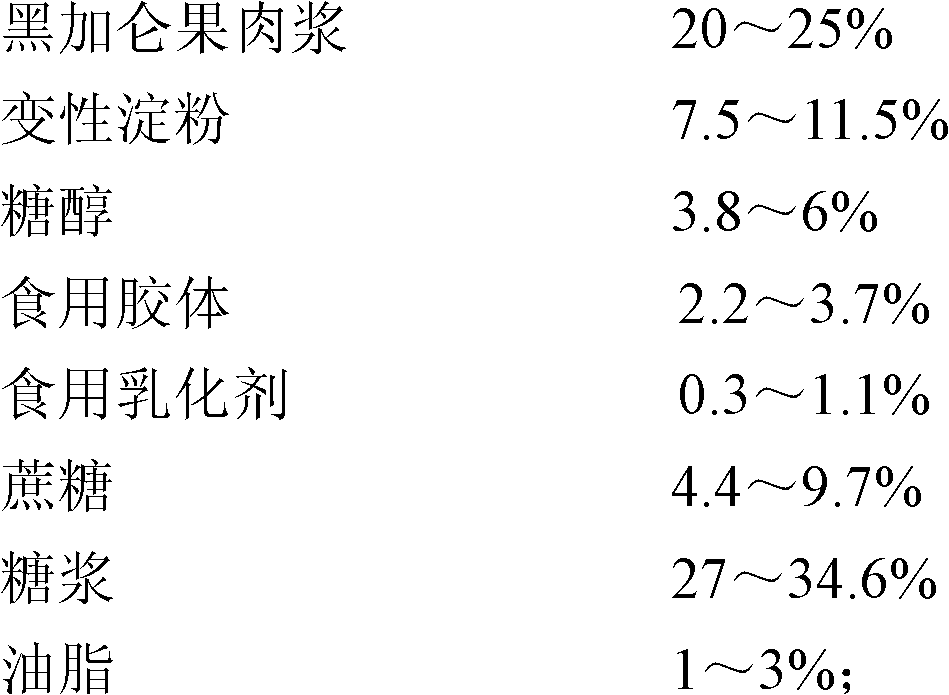

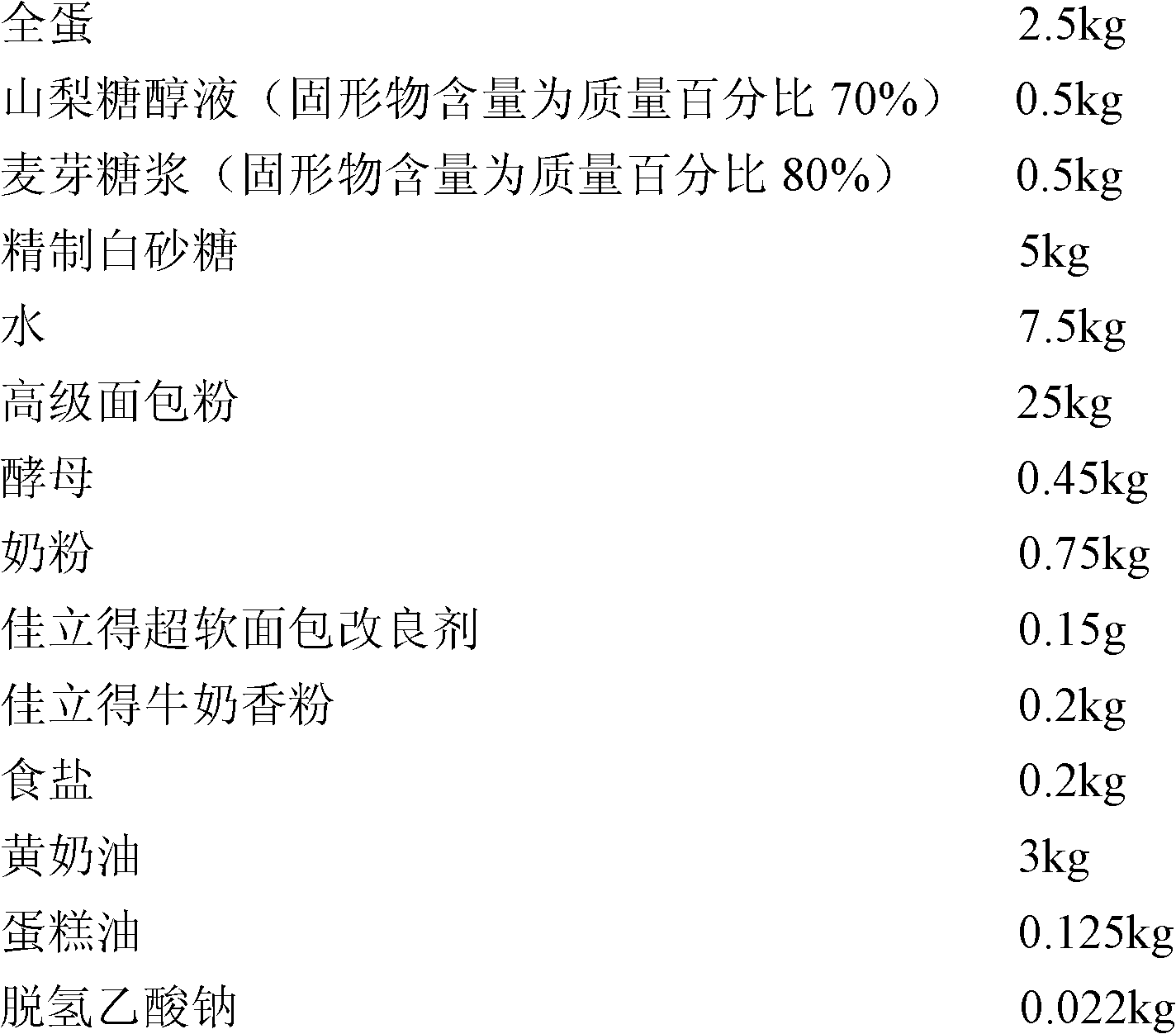

[0038] (1) The blackcurrant dried fruit pulp with a particle diameter of 0.6 to 0.8cm and a water content of 15 to 20% by mass is mixed with water in a mass ratio of 1:1, and placed for 3 hours, so that the dried blackcurrant pulp can fully Soak, heat and boil for 30 minutes and then whip to obtain black currant pulp.

[0039] (2) 15kg hydroxypropyl distarch phosphate, 12kg maltitol, 1.4kg sodium carboxymethyl cellulose, 3kg pectin, 2.2kg molecular distillation monoglyceride and 0.2kg potassium sorbate are mixed, cross 20 mesh sieves, Throw it into a jacketed pot and stir evenly with 19.4kg of refined white granulated sugar.

[0040] (3) Pour 46kg of water into the jacketed pot, stir until there are no visible particles, pour 54kg of maltose syrup (the solid content is 85% by mass) and 6kg of soybean oil, turn on the steam, heat up to 90-95°C, and keep warm 15 minutes; after the gelatinization is complete, put 40 kg of the black currant pulp slurry prepared in step (1) into t...

Embodiment 2

[0043] (1) 23kg oxidized hydroxypropyl starch, 7.6kg sorbitol, 5.4kg pectin, 2kg locust bean gum, 0.3kg calcium stearoyl lactylate, 0.3kg sodium stearoyl lactylate and 0.2kg sodium dehydroacetate are mixed, Pass through a 20-mesh sieve, put into a sandwich pot, and stir evenly with 8.8kg of refined white granulated sugar.

[0044] (2) Pour 30kg of water into the jacketed pot, stir until there are no visible particles, pour 69.2kg of glucose syrup (the solid content is 85% by mass) and 2kg of soybean oil, turn on the steam, and heat up to 90-95°C, Keep warm for 15 minutes.

[0045] (3) After gelatinization is complete, 50kg black currant pulp slurry (prepared by embodiment 1 step (1)) is dropped into the jacketed pot, continue to stir and keep warm for 5 minutes, and control the solid content to be 65~68%.

[0046] (4) Turn on cooling water, cool down to about 70°C, put 1kg of malic acid and 0.2kg of blackcurrant essence into the jacketed pot, cool to below 50°C for filling, a...

Embodiment 3

[0048](1) 19kg hydroxypropyl distarch phosphate, 8kg xylitol, 2.2kg carrageenan, 4kg konjac gum, 1.5kg modified soybean lecithin and 0.2kg potassium sorbate are mixed, cross 20 mesh sieves, drop into sandwich pot, Stir evenly with 14kg refined white granulated sugar.

[0049] (2) Pour 35kg of water into the jacketed pot, stir evenly until no particles are visible to the naked eye, pour 65.1kg of maltose syrup (the solid content is 85% by mass) and 4kg of snow-white emulsified oil, turn on the steam, and heat up to 90-95°C , keep warm for 15 minutes.

[0050] (3) After the gelatinization is complete, 46kg of black currant pulp (prepared by the step (1) of Example 1) is dropped into the jacketed pot, continue to stir and keep warm for 5 minutes, and control the solid content to be 65% to 68%.

[0051] (4) Turn on the cooling water, cool down to about 70°C, put 0.4kg of citric acid, 0.2kg of malic acid, and 0.4kg of blackcurrant essence into the jacketed pot, cool to below 50°C ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com