Rapid making method for all-natural fruit wine

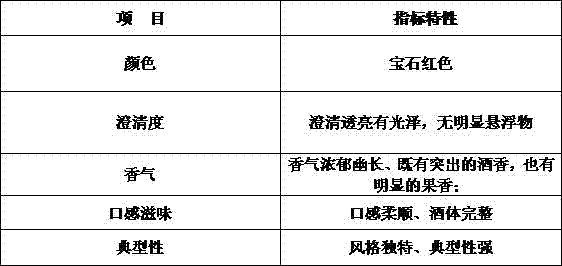

A fruit wine brewing, pure natural technology, applied in the field of brewing, can solve problems such as 1 year, some 2 years, or even more than 3 years, increased production costs, and difficulty in maintaining naturalness, so as to overcome potential hazards and improve work efficiency. , Guaranteed natural effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment l

[0034] The brewing method of pure natural fruit wine of the present invention, it comprises following processing step:

[0035] a. Screening and inspection of fruit raw materials. The fruit varieties are Cabernet Sauvignon and Merlot grapes. The fruit raw materials are disease-free, clean and non-rotten, and the ear shape is typical and complete, and the fruit grains are evenly ripe;

[0036] b. Impurity removal: Wash selected fruit raw materials and remove non-fermentable impurities such as leaves and fruit stems;

[0037] c. Cleaning and disinfection Carry out comprehensive CIP, SIP cleaning and disinfection or sterilization of the tank pipes of brewing equipment and their supporting equipment and facilities. The cleaning method is cold water first and then hot water, and the disinfection or sterilization method used is steam disinfection;

[0038] d. Crushing The crushing method is the conventional mechanical crushing method;

[0039] e. The crushed fruit pulp after inocul...

Embodiment 2

[0047] The brewing method of pure natural fruit wine of the present invention, it comprises following processing step:

[0048] a. Screening and inspection of fruit raw materials, the fruit variety is pomegranate, the fruit raw materials are disease-free, clean and non-rotten, and the fruit shape is typical, complete, and evenly ripe;

[0049] b. Impurity removal: Wash selected fruit raw materials and remove non-fermentable impurities such as leaves, fruit stems, and peels;

[0050] c. Cleaning and disinfection Carry out comprehensive CIP, SIP cleaning and disinfection or sterilization of the tank pipes and supporting equipment and facilities of brewing equipment, and the disinfection or sterilization method used is alcohol disinfection;

[0051] d. Crushing The crushing method is manual crushing;

[0052] e. The crushed fruit pulp after inoculation and fermentation is pumped directly into the multifunctional fruit wine brewing system, and then inoculated and fermented at 32°...

Embodiment 3

[0060] The brewing method of pure natural fruit wine of the present invention, it comprises following processing steps:

[0061] a. Screening and inspection of fruit raw materials. The fruit varieties are apples and pears. The fruit raw materials are disease-free, clean and non-rotten.

[0062] b. Impurity removal: Wash selected fruit raw materials and remove non-fermentable impurities such as leaves, fruit stems, and fruit stones;

[0063] c. Cleaning and disinfection Carry out comprehensive CIP, SIP type cleaning and disinfection or sterilization on the tank pipes and supporting equipment and facilities of brewing equipment, and the disinfection or sterilization method used is ozone disinfection;

[0064] d. Crushing The crushing method is a mechanical method with a bridge breaking device and a screw propeller;

[0065] e. The crushed fruit pulp after inoculation and fermentation is pumped directly into the multi-functional fruit wine brewing system, and then inoculated and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com