Processing method of dry type fragrant pear fermented wine

A processing method and technology for perfumed pears, applied in the field of food processing, can solve the problems of restricting the expansion and sales of perfumed pears, single product, poor quality, etc., and achieve the effect of improving the juice yield.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] 1) Choose fresh perfume pears that are fully mature, soluble solids above 12°Bx, no rot, no diseases and insect pests.

[0018] 2) Rinse the fresh pears with running water, drain them and avoid mechanical damage.

[0019] 3) Wash and drain the pears at 0~5℃ for 24h, -5~-10℃ for 24h, -18~-20℃ for 2~4 days.

[0020] 4) Frozen pears are naturally thawed at room temperature, crushed, and juiced. Adjust the juice pH to 3.8 with citric acid, add 50mg / L potassium metabisulfite, and clarify naturally at low temperature (0-12°C). The clarified pear juice is divided into four equal groups for fermentation.

[0021] 5) The low-temperature expansion steps of Saccharomyces cerevisiae WL300, D576, and WET136 are the same as step 5 in Example 1).

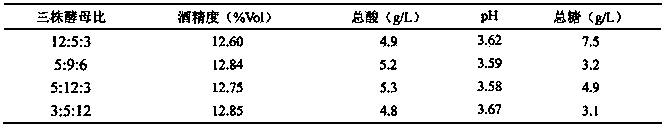

[0022] 6) Mix the expansion solutions of the three low-temperature Saccharomyces cerevisiae obtained in step 5). The mixing volume ratios of WL300, D576, and WET136 are 12:5:3, 5:9:6, 5:12:3, 3:5, respectively. :12. Add the different mixtures of th...

Embodiment 2

[0029] 1) Fresh perfume pears that are fully ripe, soluble solids above 12°Bx, no rot, no diseases and insect pests.

[0030] 2) Rinse the fresh pears with running water, drain them and avoid mechanical damage.

[0031] 3) Pre-cool the washed and drained pears at 0~5℃ for 24h, -5~-10℃ for 24h, and -18~-20℃ for 2~4 days.

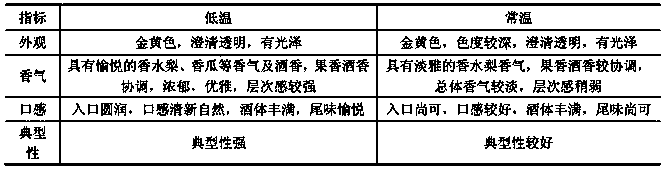

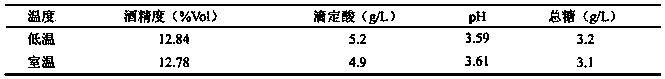

[0032] 4) Frozen pears are naturally thawed at room temperature, crushed, and squeezed. The pH of the juice is adjusted to 3.8 with citric acid, and 50mg / L potassium metabisulfite is added at low temperature (10~12℃) and room temperature (20~22℃). ) Under clarification of the juice, two pear juices were obtained, temporarily labeled as low temperature pear juice and room temperature pear juice.

[0033] 5) The low-temperature expansion steps of Saccharomyces cerevisiae WL300, D576, and WET136 are the same as step 5 in Example 1).

[0034] 6) Mix the expansion solutions of the three low-temperature Saccharomyces cerevisiae obtained in step 5), the mixing volume ratio o...

Embodiment 3

[0043] 1) Choose fresh perfume pears that are fully mature, soluble solids above 12°Bx, no rot, no diseases and insect pests.

[0044] 2) Rinse the fresh pears with running water, drain them and avoid mechanical damage.

[0045] 3) Pre-cool the washed and drained pears at 0~5℃ for 24h, -5~-10℃ for 24h, and -18~-20℃ for 2~4 days.

[0046] 4) Naturally thaw frozen pears at room temperature, crush and squeeze the juice, adjust the pH of the juice to 3.8 with citric acid, add 50mg / L potassium metabisulfite, and clarify naturally at low temperature (0-12°C). Take clarified pear juice and divide it into three equal groups for fermentation.

[0047] 5) Three strains of Saccharomyces cerevisiae WL300, D576, and WET136 were expanded and cultured at low temperature: Take the preserved strains and activate them in a liquid test tube (with pear juice inside) at 22~25℃ for 2 days to obtain an activation culture solution; Inoculate the inoculum volume (volume ratio) into the liquid Erlenmeyer flas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com