Chromic oxide refractory material and preparation method thereof

A refractory material and chromium oxide technology, which is applied in the field of chromium oxide refractory materials and its preparation, can solve the problems of reducing the service life of kilns, difficulty in drawing operations, and increasing production costs, so as to improve thermal shock resistance, improve drawing quality and Production efficiency and the effect of reducing investment costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

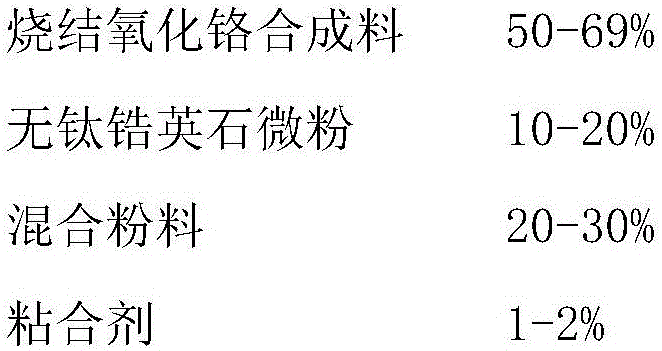

[0030] The chromium oxide refractory material of the present invention, its raw material component comprises the following components according to weight ratio:

[0031]

[0032] Among them, the particle size of chromium oxide powder in the sintered chromium oxide synthetic material is less than 10 μm; the particle size of silicon oxide powder is less than 3 μm; the particle size of titanium oxide powder is less than 10 μm.

[0033] The preparation method of above-mentioned chromium oxide refractory material, comprises the following steps:

[0034] S1: Take 85-95% of chromium oxide powder, 0.2-3% of silicon oxide powder and 2-6% of titanium oxide powder according to the weight ratio. The sintered chromium oxide synthetic pellets, stand-by;

[0035] S2: According to the weight ratio, 85-95% of chromium oxide, 1-6% of zirconia content, 0.5-3% of silicon oxide content and 2-6% of titanium oxide content are taken, and the sum of the quantities of each component is equal to 100...

Embodiment 2

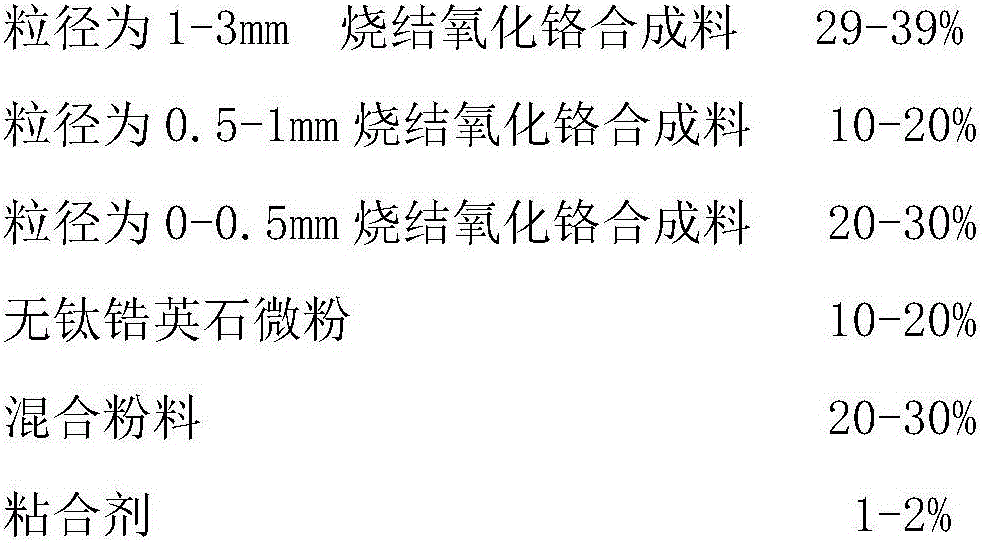

[0039] The chromium oxide refractory material of the present invention, its raw material components comprise the following components according to the weight ratio:

[0040]

[0041] Among them, the particle size of chromium oxide powder in the sintered chromium oxide synthetic material is less than 10 μm; the particle size of silicon oxide powder is less than 3 μm; the particle size of titanium oxide powder is less than 10 μm.

[0042] The preparation method of the above-mentioned chromium oxide refractory material is consistent with Example 1. Among them, the high temperature firing temperature is 1625°C. .

Embodiment 3

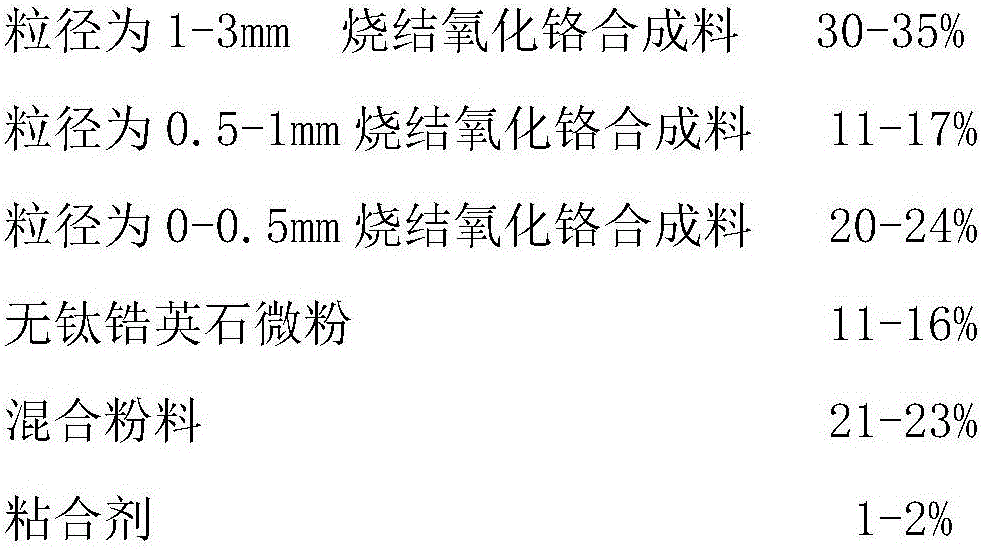

[0044] The chromium oxide refractory material of the present invention, its raw material components comprise the following components according to the weight ratio:

[0045]

[0046] Among them, the particle size of chromium oxide powder in the sintered chromium oxide synthetic material is less than 10 μm; the particle size of silicon oxide powder is less than 3 μm; the particle size of titanium oxide powder is less than 10 μm.

[0047] The preparation method of the above-mentioned chromium oxide refractory material is consistent with Example 1. Among them, the high temperature firing temperature is 1620°C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com