Magnetorheological elastomer, preparation method and application thereof

A technology of magnetorheological elastomers and elastomers, applied in the field of preparation and magnetorheological elastomers, can solve the problems of no unified preparation method, poor interface bonding performance, poor damping performance, etc., and achieve improved magnetotropic effect, Good damping, reducing the effect of frost heaving and cracking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

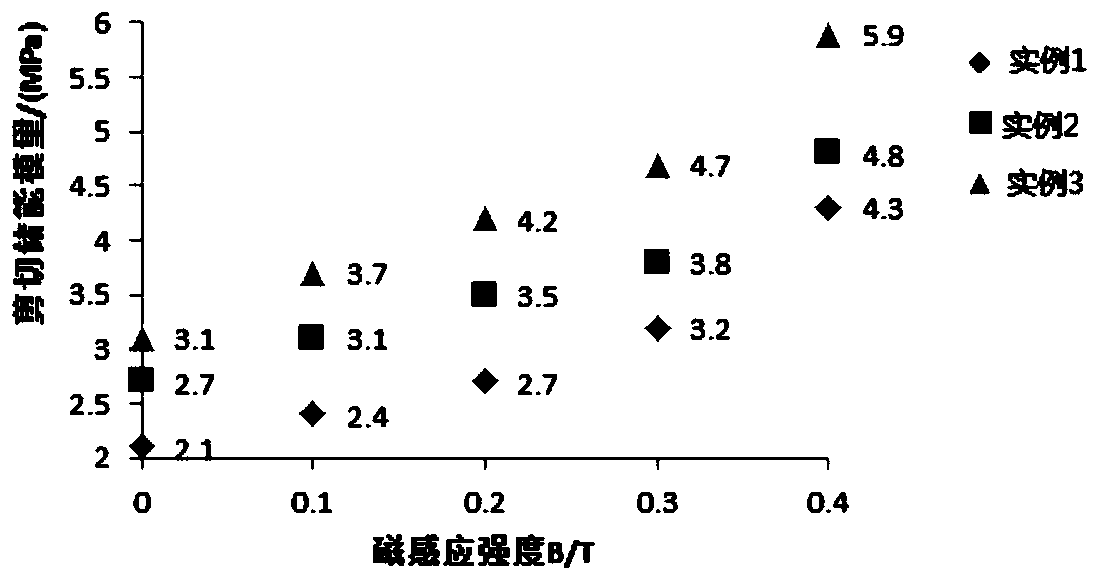

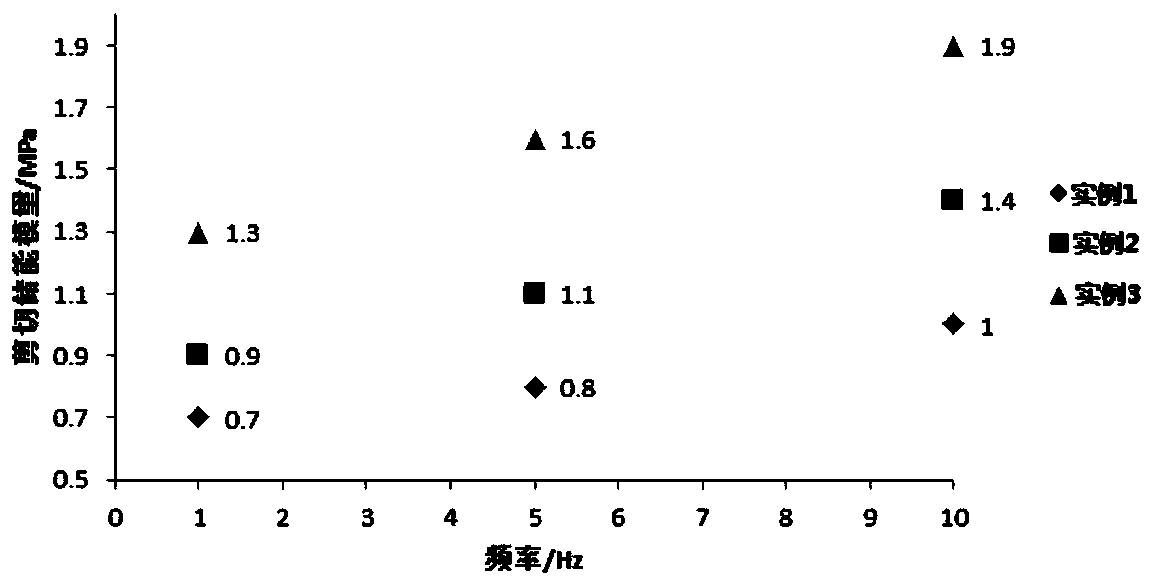

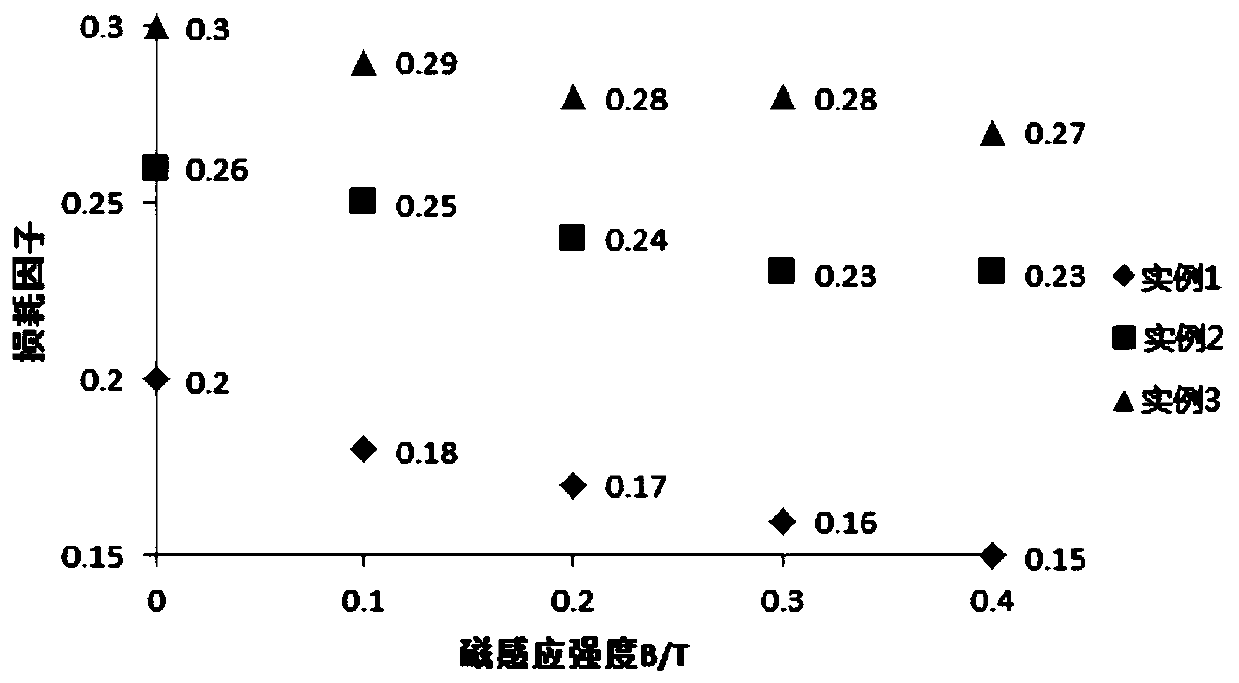

Embodiment 1

[0023] A magnetorheological elastomer, comprising the following components according to the weight ratio: 100 parts of rubber matrix, 600 parts of magnetic particles, 16 parts of vulcanizing agent and 4 parts of accelerator, 20 parts of plasticizer, 30 parts of dispersant, binder 50 parts, 10 parts of strengthening agent, 10 parts of cold resistance agent.

[0024] Among them, the rubber matrix is made of silicon rubber, and the magnetic particles are made of micron-sized carbonyl iron powder and silicon steel powder, with a ratio of 25:1. The vulcanizing agent is selenium, the vulcanization accelerator is calcium oxide; the plasticizer is dimethyl silicone oil, the dispersant is methyl amyl alcohol, the binder is silicon carbide, the cold resistance agent is adipate, and the reinforcing agent is gas phase method Silica.

[0025] The above-mentioned preparation method of a magnetorheological elastomer comprises the following steps:

[0026] Step 1: Weigh according to the a...

Embodiment 2

[0032] A magneto-rheological elastomer, each component includes: 125 parts of rubber matrix, 650 parts of magnetic particles, 20 parts of vulcanizing agent, 4.5 parts of accelerator, 25 parts of plasticizer, 40 parts of dispersant, binder 55 parts, 15 parts of strengthening agent, 15 parts of cold resistance agent.

[0033] Among them, the rubber matrix is made of silicon rubber, and the magnetic particles are made of micron-sized carbonyl iron powder and silicon steel powder, with a ratio of 25:1. The vulcanizing agent is selenium, the vulcanization accelerator is magnesium oxide; the plasticizer is dimethyl silicone oil, the dispersant is polyurethane, the binder is graphene, the cold-resistant agent is adipate, and the reinforcing agent is fumed white carbon black.

[0034] The preparation method and application of the aforementioned magnetorheological elastomer are the same as those in Example 1.

Embodiment 3

[0036] A magnetorheological elastomer, each component includes: 150 parts of rubber matrix, 700 parts of magnetic particles, 25 parts of vulcanizing agent, 5 parts of accelerator, 30 parts of plasticizer, 50 parts of dispersant, binder 60 parts, 20 parts of strengthening agent, 20 parts of cold resistance agent.

[0037] Among them, the rubber matrix is made of silicon rubber, and the magnetic particles are made of micron-sized carbonyl iron powder and silicon steel powder, with a ratio of 25:1. The vulcanizing agent is selenium, the vulcanization accelerator is calcium oxide; the plasticizer is dimethyl silicone oil, the dispersant is methyl amyl alcohol, the binder is carbon nanotubes, the cold resistance agent is adipate, and the reinforcing agent is gas phase French silica.

[0038] The preparation method and application of the aforementioned magnetorheological elastomer are the same as those in Example 1.

[0039] The cylinder magnetorheological elastomer molds with a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com