Method for preparing spherical carbonate

A technology of carbonate and ammonium carbonate, applied in nickel carbonate, cobalt carbonate, chemical instruments and methods, etc., can solve the problems of high energy consumption, high processing and operation costs, and achieve low energy consumption, excellent indicators, The effect of reducing consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

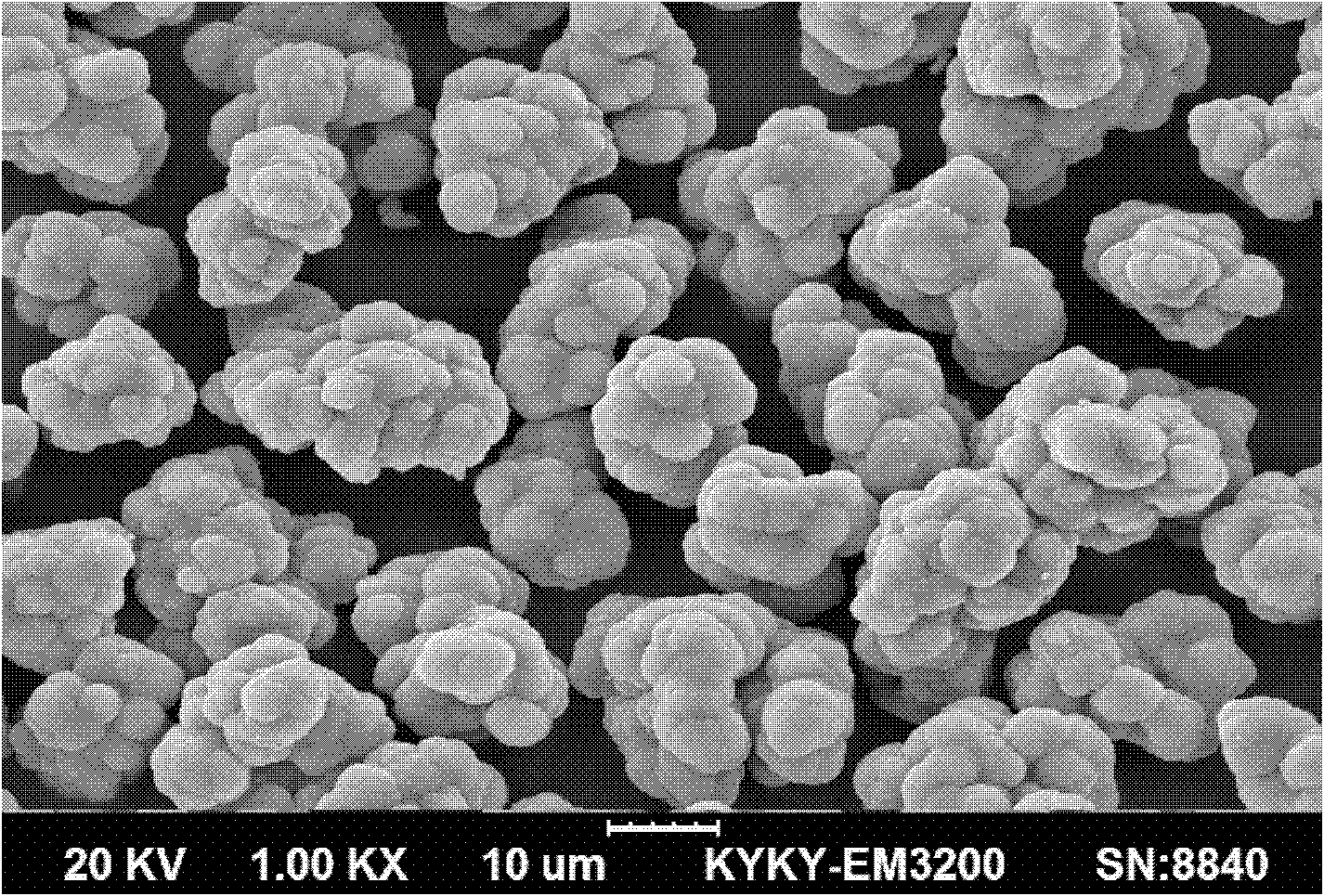

Embodiment 1

[0021] Use the tail liquid ammonium chloride as the bottom liquid to synthesize spherical cobalt carbonate, complete in the following steps:

[0022] 1. Prepare the cobalt chloride solution with a concentration of 80g / L and the ammonium bicarbonate solution with a concentration of 150g / L;

[0023] 2. to 3m 3 Add 0.3m to the synthesis kettle 3 The tail liquid is used as the synthetic bottom liquid;

[0024] 3. Stir to heat up the bottom liquid, and stop heating when the temperature of the bottom liquid reaches 40-50°C;

[0025] 4. Start to add cobalt chloride solution and ammonium bicarbonate solution in parallel, the addition rate of metal chloride salt is 330L / h, the addition rate of ammonium carbonate salt is 600L / h, feed 2h, ammonium chloride, chloride in the tail liquid The mass ratio between cobalt chloride solution and ammonium bicarbonate is controlled at 0.06:1:3.4.

[0026] 5. The pH value of the solution at the end of the feeding is 7.0, and the temperature is ag...

Embodiment 2

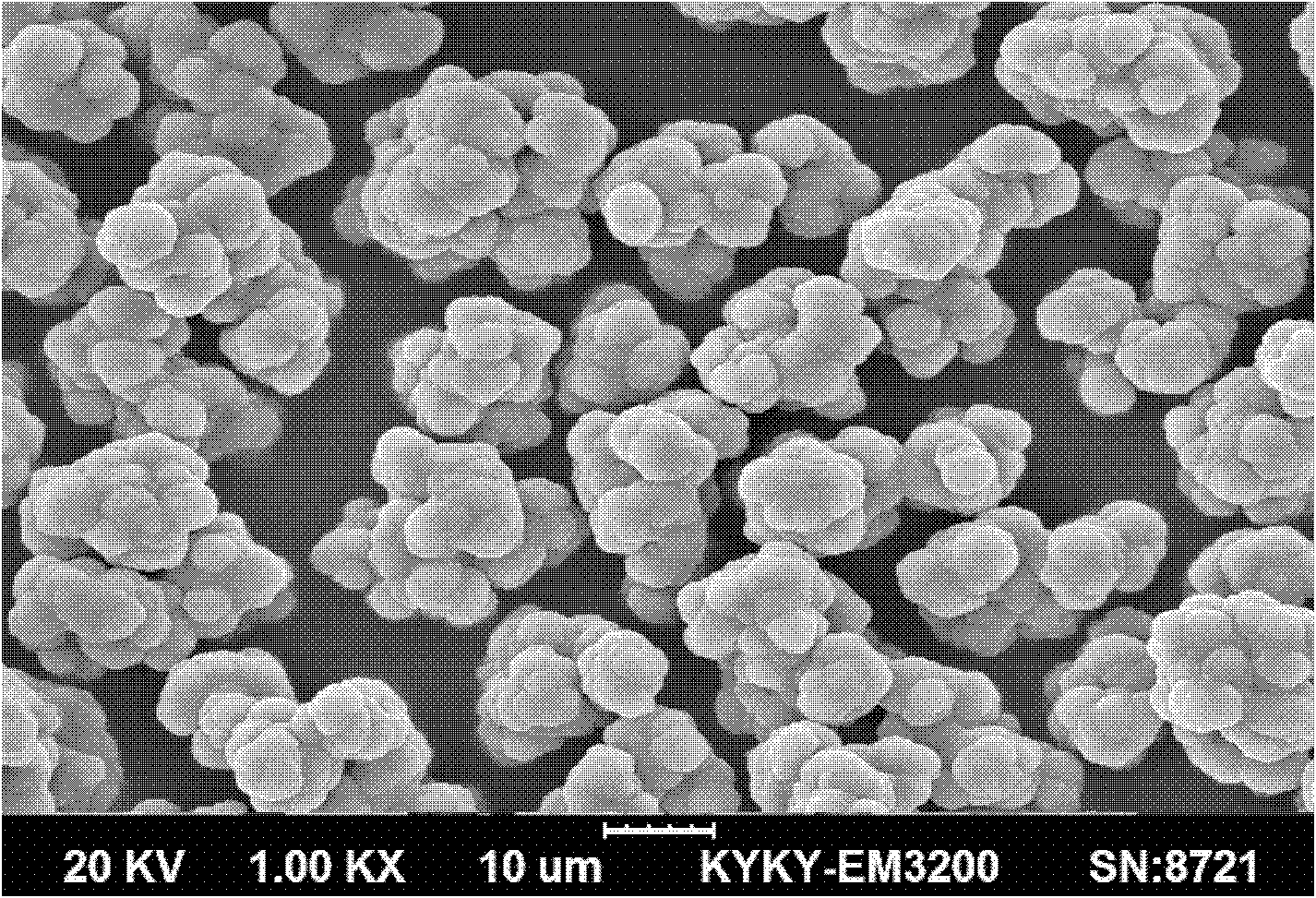

[0031] Synthesize spherical nickel carbonate with tail liquid as bottom liquid, complete in the following steps:

[0032] 1. The concentration of the prepared nickel chloride solution is 150g / L, and the concentration of the ammonium bicarbonate solution is 230g / L.

[0033] 2. to 3m 3 Add 0.3m to the synthesis kettle 3 The tail liquid is used as the synthetic bottom liquid;

[0034] 3. Stir to heat up the bottom liquid, and stop heating when the temperature of the bottom liquid reaches 70-80°C;

[0035] 4. The addition speed of metal chloride salt is 380L / h, the addition speed of ammonium carbonate salt is 800L / h, feed 2h, the mass ratio between ammonium chloride, nickel chloride solution and ammonium bicarbonate in the tail liquid Controlled at 0.08:1:3.2.

[0036] 5. The pH value of the solution at the end of the feeding is 7.5, and the temperature is aged for 2 hours;

[0037] 6. After the aged slurry is filtered, washed and dried, a spherical nickel carbonate product i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com