Method and system for preparing cobalt carbonate

A technology of cobalt carbonate and cobalt carbonate crystal, applied in the direction of cobalt carbonate, can solve the problems of low tap density and high energy consumption of cobalt carbonate, and achieve the effects of high sphericity, increased solid content and increased efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

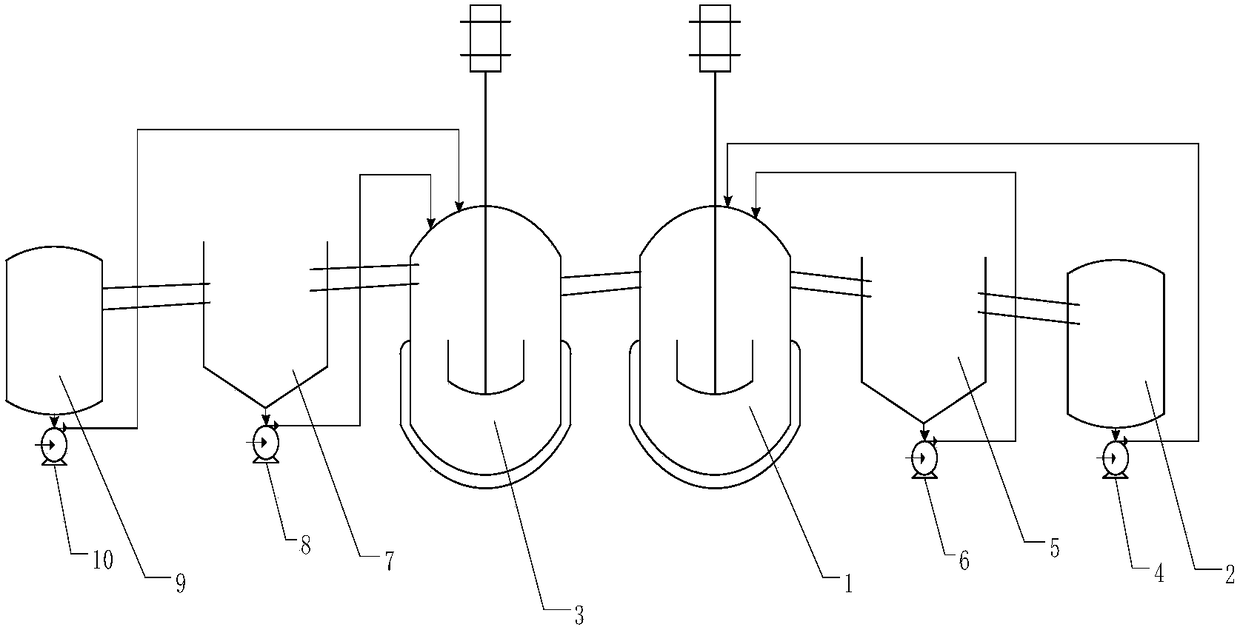

Method used

Image

Examples

Embodiment 1

[0040] Bottom liquid preparation stage: to 8m 3 The ammonium bicarbonate solution with a flow rate of 1000 L / h and a concentration of 215 g / L was added to the seed crystal tank through a metering pump for 3 minutes. Then, add water to the second layer of stirring paddle of the seed crystal kettle in the seed crystal kettle, and open the steam valve. When the temperature in the seed crystal tank increased to 50° C., the stirring speed of the motor was adjusted to 1300 r / min.

[0041] Primary feeding stage: start cobalt salt solution metering pump and ammonium bicarbonate solution metering pump, the concentration of the cobalt salt solution that adds in seed crystal still is 130g / L, flow rate is 460L / h; The concentration of the ammonium bicarbonate solution that adds is 215g / L, the flow rate is 1000L / h. Within 12 hours of the reaction, the flow rate of the cobalt salt solution remained unchanged; and within 1 hour of the initial reaction, the pH value in the seed crystal tank ...

Embodiment 2

[0047] The difference between this embodiment and embodiment 1 is that in the bottom liquid preparation stage, the 8m 3 The ammonium bicarbonate solution with a flow rate of 1000 L / h and a concentration of 210 g / L was added to the seed crystal tank through a metering pump for 5 minutes. Then, add water to the second layer of stirring paddle of the seed crystal kettle in the seed crystal kettle, and open the steam valve. When the temperature in the seed crystal tank increased to 48° C., the stirring speed of the motor was adjusted to 1100 r / min.

[0048] By the method of embodiment 2, the particle diameter D50 of the cobalt carbonate finished product that obtains is 17.8 μ m, tap density is 2.8g / cm 3 , and less small particles.

Embodiment 3

[0050] The difference between this embodiment and Example 1 is that in the primary feeding stage, the concentration of the cobalt salt solution added to the seed crystal tank is 140g / L, and the flow rate is 460L / h; the concentration of the added ammonium bicarbonate solution is 225g / L, the flow rate is 1000L / h. Within 12 hours of the reaction, the flow rate of the cobalt salt solution remained unchanged; and within 1 hour of the initial reaction, the pH value in the seed crystal tank slowly decreased to 7.4. After 12 hours of reaction, the pH value in the seed tank was maintained at 7.0-7.4, and the stirring speed of the motor was adjusted to 900 r / min.

[0051] By the method of embodiment 3, the particle diameter D50 of the cobalt carbonate finished product that obtains is 16.8 μ m, tap density is 2.6g / cm 3 , and less small particles.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Tap density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com