Method for preparing small-particle size large-bulk cobalt carbonate

A technology of cobalt carbonate and small particle size, applied in cobalt carbonate and other directions, can solve the problems of poor controllability and large size range of cobalt carbonate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

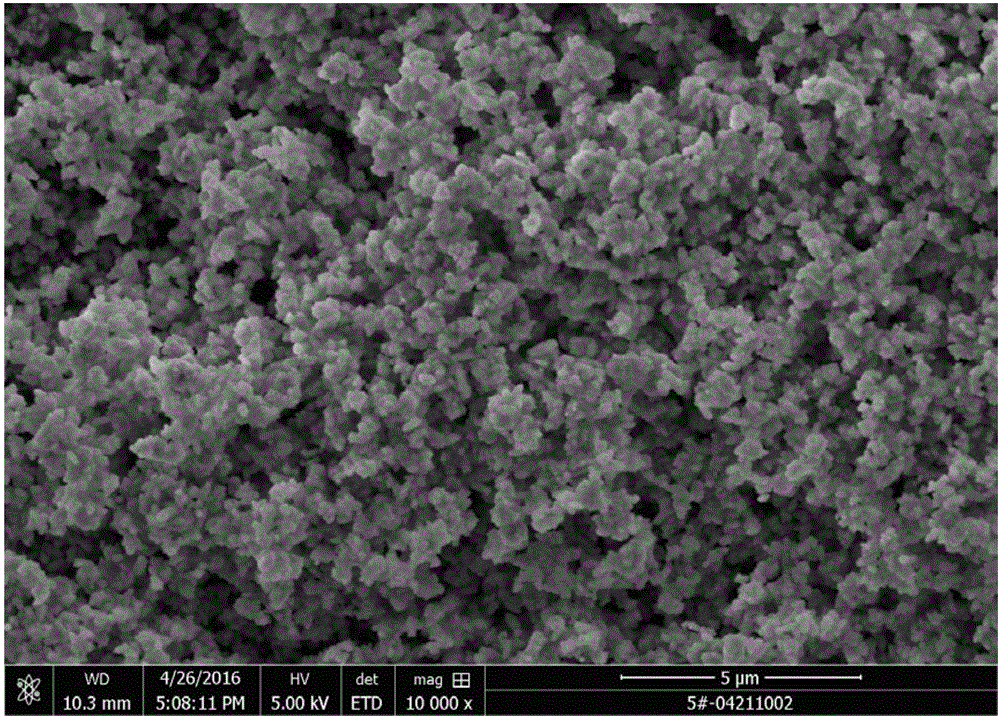

Embodiment 1

[0027] The raw material solutions were prepared as follows: a cobalt chloride solution with a concentration of 120 g / L, an ammonium bicarbonate solution with a concentration of 220 g / L, and an ammonium bicarbonate solution with a concentration of 60 g / L.

[0028] Among them, the role of the ammonium bicarbonate base solution is to keep the precipitant excessive. When the cobalt chloride is dripped, the supersaturation is very large, and it immediately nucleates into small particles of cobalt carbonate, so that the number of nucleation is large and small, which helps In the later stage, the cobalt carbonate grains increase the degree of compaction.

[0029] Add 1000L of ammonium bicarbonate solution with a concentration of 60g / L as the bottom liquid into the reaction kettle, raise the temperature to 40℃, and add cobalt chloride solution and ammonium bicarbonate solution into the bottom liquid in parallel, where the flow rate of the cobalt chloride solution It is 600L / h, the flow rat...

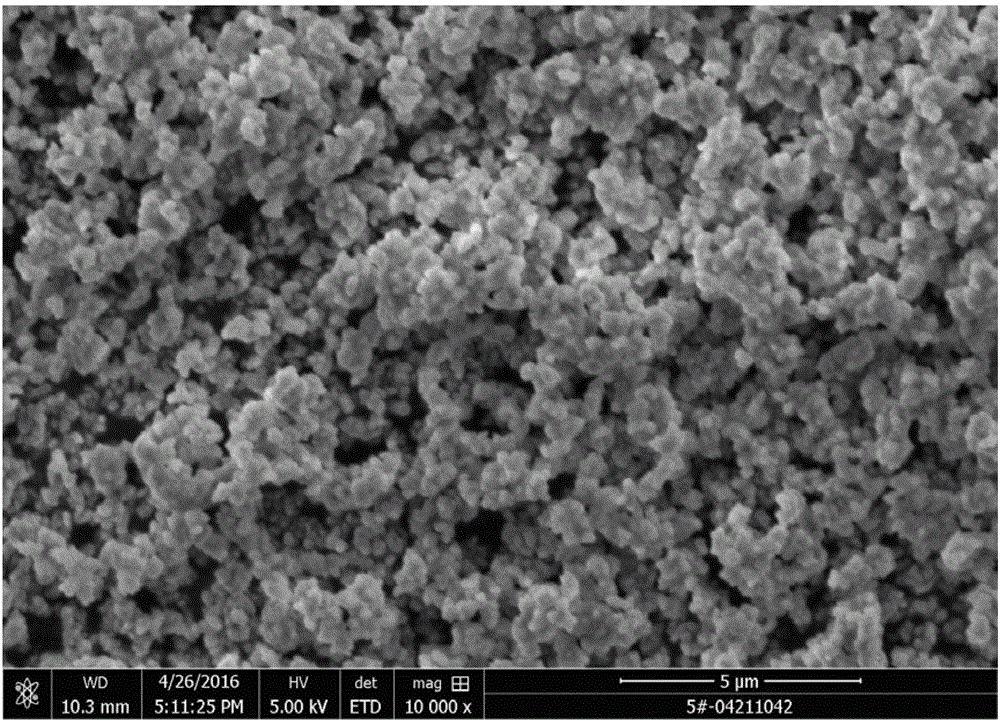

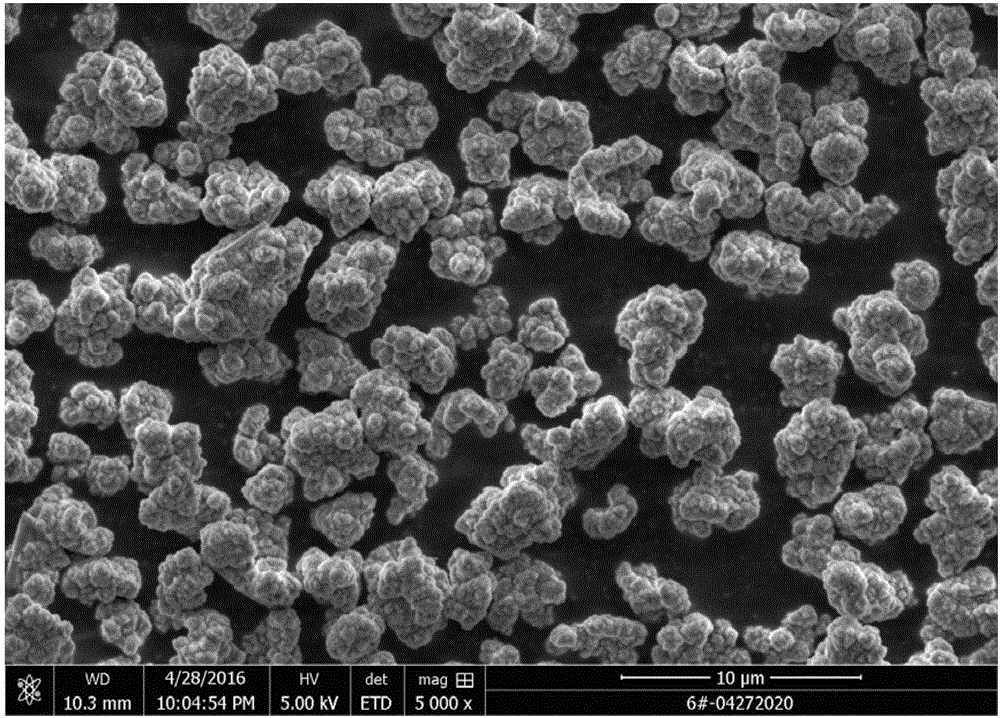

Embodiment 2~5

[0034] On the basis of Example 1, some parameters in the preparation method of cobalt carbonate were subjected to comparative experiments. In Examples 2 to 5, the same reaction solution concentration parameters as in Example 1 were used, namely: the concentration of 120g / l Cobalt chloride solution, ammonium bicarbonate solution with a concentration of 220g / L, ammonium bicarbonate solution with a concentration of 60g / L, and ammonium bicarbonate solution with a concentration of 60g / L as the bottom liquid.

[0035] The following Tables 1 and 2 are the reaction process parameters of Examples 2-5.

[0036] Table 1 shows the process parameters of seed crystal generation in Examples 2-5

[0037] Serial number Base fluid volume Cobalt chloride flow Ammonium bicarbonate flow Seed growth time PH value at the end of the reaction 21000L 600L / h 900L / h1.5h7.1 31300L 600L / h 900L / h1.5h7.15 41900L 600L / h 900L / h1.5h7.15 51900L 600L / h 900L / h1.5h7.25

[0038] Table 2 shows the parameters of the seed...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| bulk density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com