Method for producing cobalt carbonate

A production method and technology of cobalt carbonate, applied in the direction of cobalt carbonate, etc., can solve the problems of difficult washing, difficult filtration, and high cobalt content, and achieve the effects of ensuring bulk density, solving diffusion problems, and good processing performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

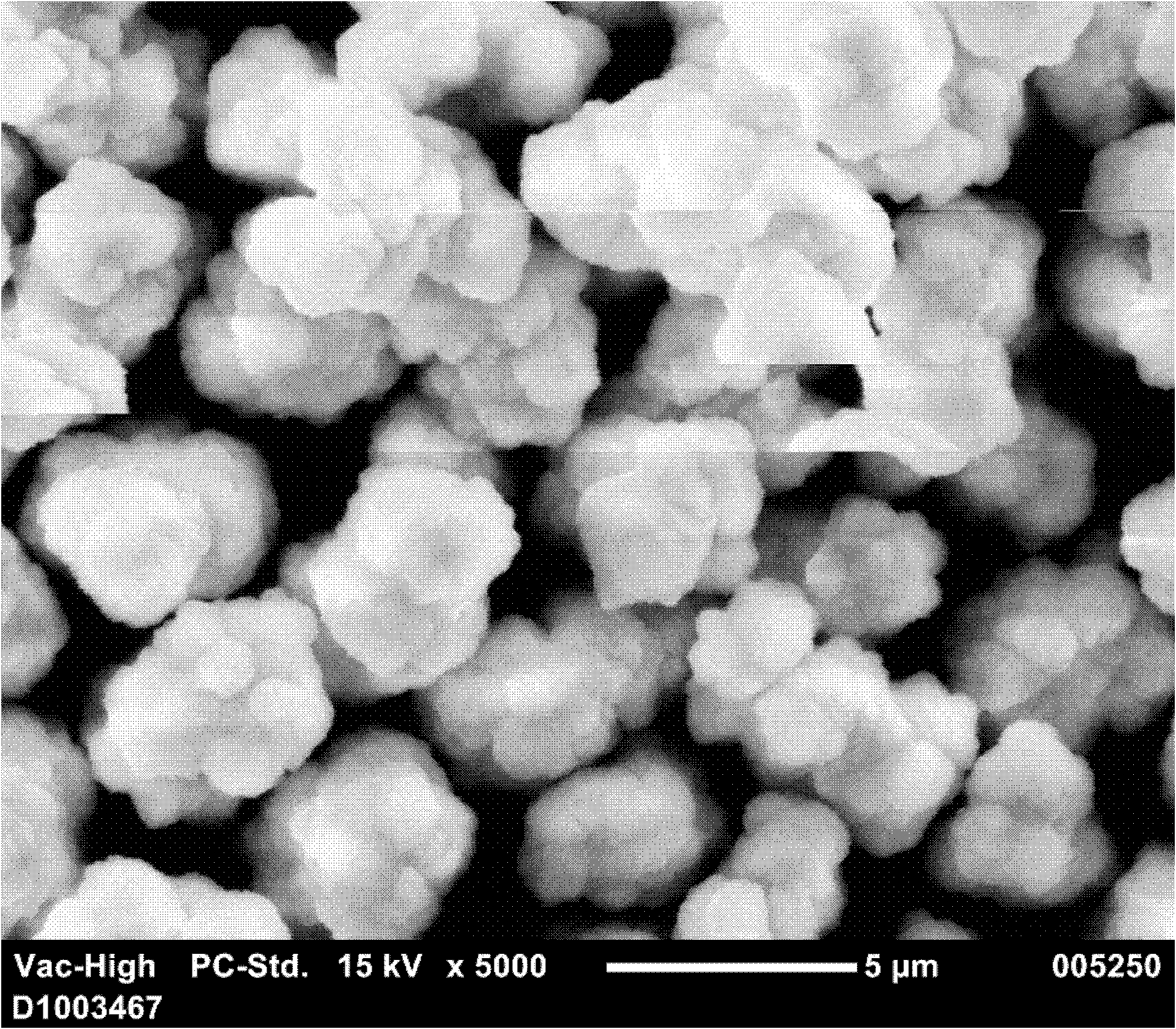

[0017] to 2m 3 Add 950L of NH with a concentration of 250±10g / L to the reactor 4 HCO 3 , heated to 50°C, 575L of CoCl with a cobalt concentration of 130±5g / L at a stirring speed of 110 rpm 2 The solution was fast and then slow within 4h (starting rate of addition was 190 ± 10L / h, and along with the dropping of cobalt chloride solution, the color was dark red gradually; when the color of the solution appeared pink, the rate of addition changed to slow addition, Control the dropping rate to be 90 ± 10L / h, and add NH at a speed of 2h for fast and slow addition. 4 HCO 3 In the process, after the synthesis is completed, continue to stir for 1 hour and then carry out solid-liquid separation, wash the filter cake with pure water at 70°C until the pH of the solution is 7, and then dry it after dehydration to obtain the product. The chlorine content in the product is less than 0.02%, the yield is 99.5%, the cobalt content in the mother liquor is 0.03g / L, the primary particle D of t...

Embodiment 2

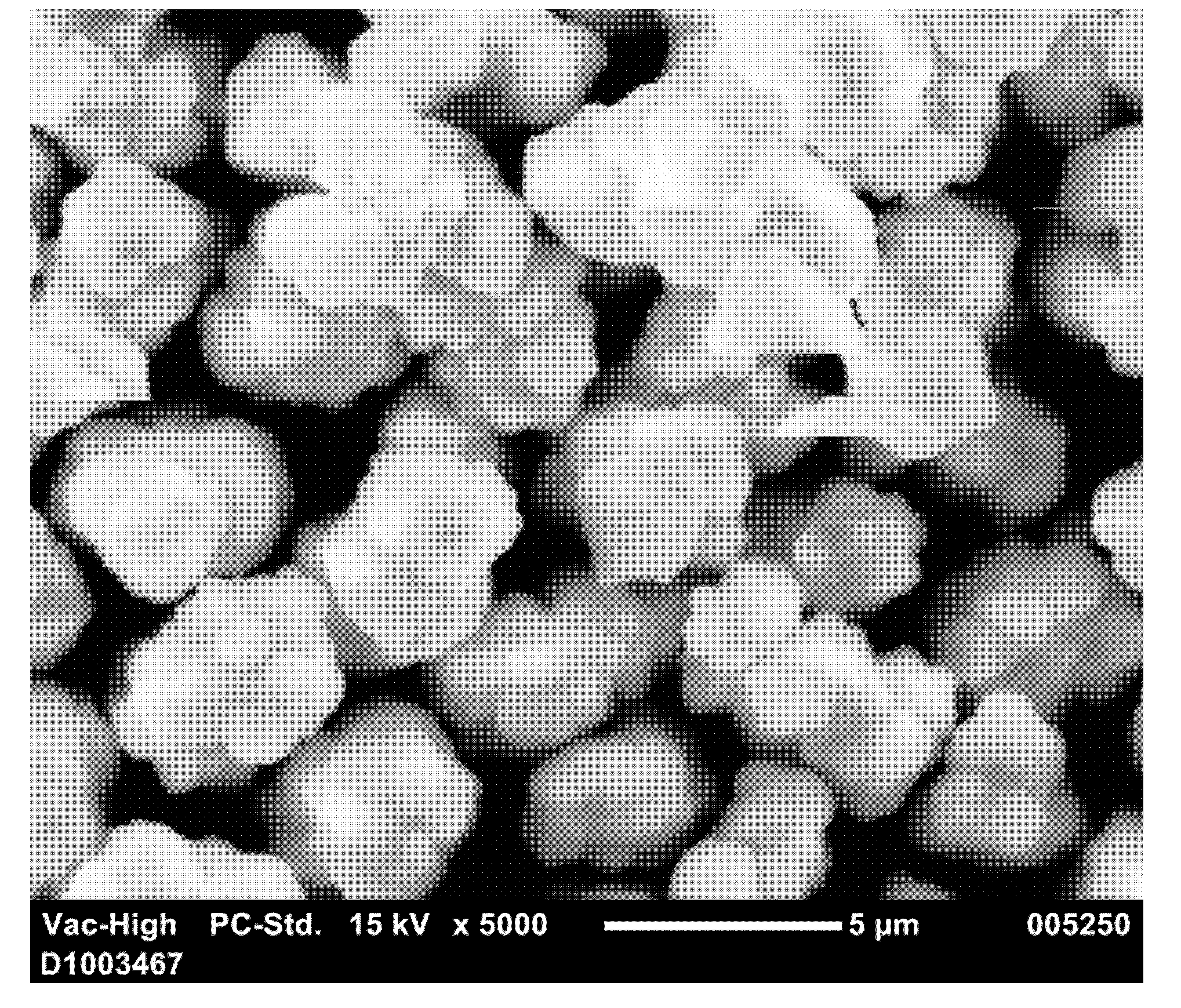

[0019] to 8m 3 Add 3800L of NH with a concentration of 250±10g / L into the reactor 4 HCO 3 , heated to 55 ° C, under the condition of a stirring speed of 130 rpm, 2300L of CoCl with a cobalt concentration of 130+5g / L 2 The speed of the solution is first fast and then slow within 8 hours (beginning to be a rapid drop section, the drop rate is 430 ± 10L / h, along with the dropwise addition of the cobalt chloride solution, the color is gradually dark red; after 3 hours, the solution color When the pink color appears, change the dropping speed to slow adding, control the dropping speed to be 130±10L / h) add NH 4 HCO 3 In the process, after the synthesis was completed, the solid-liquid separation was carried out after continuing to stir for 1 hour, and the filter cake was washed with pure water at 70° C. until the pH of the solution was 7, and then dried after dehydration to obtain the product. The chlorine content in the product is less than 0.02%, the yield is 99.5%, the cobalt ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com