Preparation method for regenerated chromium and zirconium corundum brick

The technology of zirconium corundum brick and high chrome brick is applied in the field of preparation of recycled chromium zirconium corundum brick, which can solve the problems of occupying land resources and environmental pollution, and achieve the effects of saving land resources, avoiding environmental pollution and low cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

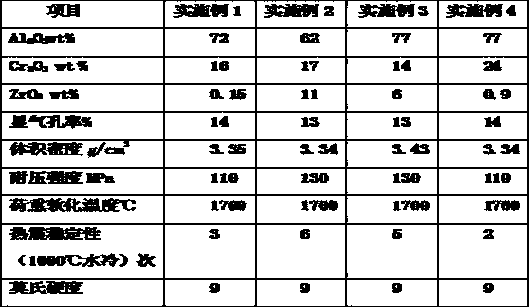

Examples

Embodiment 1

[0028] 1. Raw material preparation

[0029] Take Cr 2 o 3 ≥10wt%, Al 2 o 3 ≥75wt% aluminum chromium slag, the industrial waste slag produced by thermite production of metal chromium, is crushed and sieved into aluminum chromium slag particles with a particle size of 0-1mm, 1-3mm, and 3-5mm;

[0030] Take Cr 2 o 3 ≥10wt%, Al 2 o 3 ≥75wt% aluminum-chromium slag, the industrial waste slag produced by thermite production of metal chromium, is crushed into aluminum-chromium slag powder with a particle size of ≤0.088mm;

[0031] Take Cr 2 o 3 ≥80wt%, ZrO 2 ≥3wt%, Al 2 o 3 ≥5wt%, TiO 2 ≥1wt% Texaco coal gasifier refractory lining used waste high chromium bricks, remove the slag impregnated layer, and crush into waste high chromium brick powder with a particle size of ≤0.088mm;

[0032] 2. Brick body forming

[0033] Mix 10kg of aluminum chromium slag particles with a particle size of 0~1mm, 30kg of aluminum chromium slag particles of 1mm~3mm, 30kg of aluminum chromium ...

Embodiment 2

[0037] 1. Raw material preparation

[0038] Take Cr 2 o 3 ≥10wt%, Al 2 o 3 ≥75wt% aluminum chromium slag, the industrial waste slag produced by thermite production of metal chromium, is crushed and sieved into aluminum chromium slag particles with a particle size of 0-1mm, 1-3mm, and 3-5mm;

[0039] Take Al 2 o 3 ≥90wt% brown corundum, crushed and sieved into brown corundum particles with a particle size of 0-1mm, 1-3mm, and 3-5mm;

[0040] Take Cr 2 o 3 ≥80wt%, ZrO 2 ≥3 wt%, Al 2 o 3 ≥5wt%, TiO 2 ≥1wt% Texaco coal gasifier refractory lining used waste high chromium bricks, remove the slag impregnated layer, and crush into waste high chromium brick powder with a particle size of ≤0.088mm;

[0041] Take zirconia and pulverize it into zirconia powder with particle size ≤0.088mm;

[0042] 2. Brick body forming

[0043] 10kg of aluminum chromium slag particles with a particle size of 0~1mm, 45kg of aluminum chromium slag particles with a particle size of 1mm~3mm, 20k...

Embodiment 3

[0047] 1. Raw material preparation

[0048] Take Al 2 o 3 ≥90wt% brown corundum, crushed and sieved into brown corundum particles with a particle size of 0-1mm, 1-3mm, and 3-5mm;

[0049] Take Cr 2 o 3 ≥10wt%, Al 2 o 3≥75wt% aluminum-chromium slag, the industrial waste slag produced by thermite production of metal chromium, is crushed into aluminum-chromium slag powder with a particle size of ≤0.088mm;

[0050] Take Cr 2 o 3 ≥80wt%, ZrO 2 ≥3 wt%, Al 2 o 3 ≥5wt%, TiO 2 ≥1wt% Texaco coal gasifier refractory lining used waste high chromium bricks, remove the slag impregnated layer, and crush into waste high chromium brick powder with a particle size of ≤0.088mm;

[0051] Take zirconia and pulverize it into zirconia powder with particle size ≤0.088mm;

[0052] 2. Brick body forming

[0053] 10kg of brown corundum particles with a particle size of 0-1mm, 30kg of brown corundum particles with a particle size of 1mm-3mm, 30kg of brown corundum particles with a particle ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com