Cobalt carbonate and cobaltosic oxide granularity controlled production process

A technology of cobalt carbonate particle size and production process, which is applied in the direction of cobalt carbonate, cobalt oxide/cobalt hydroxide, etc., can solve the problems of low production quality and low yield, achieve good compactness, uniform shape and particle size, and improve calcination quality Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

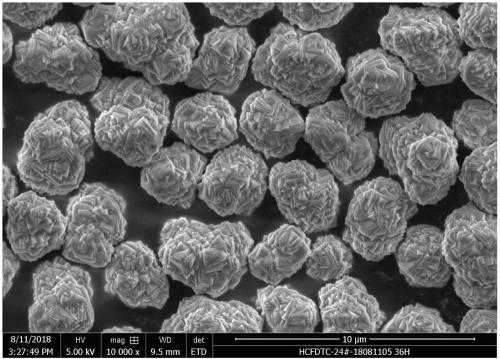

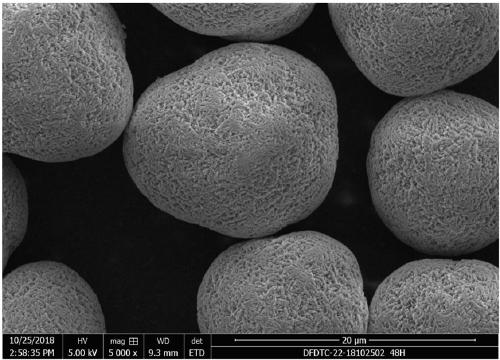

[0041] Example: A case of 18 μm step adjustment

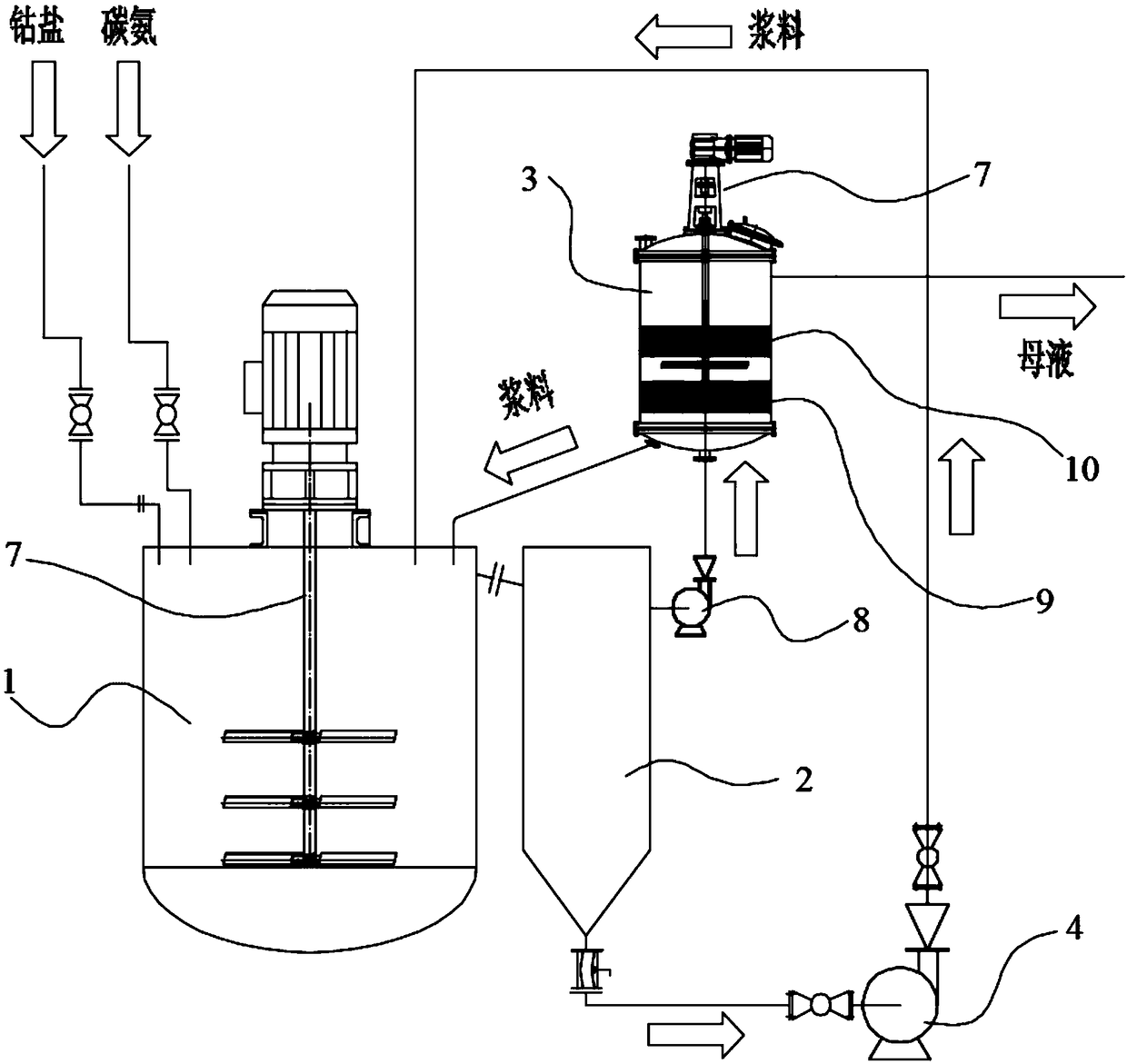

[0042] Seed reactor process with seed particle size 10.0-15.0μm: at 8m 3 Add pure water 3.5~3.8m into the titanium reactor 3 , add 1-5min ammonium bicarbonate solution through the metering pump, the flow rate of ammonium bicarbonate is controlled at 800-1000L / h, the concentration of ammonium bicarbonate solution itself is 210-250g / L, open the steam valve heated by the reaction kettle, and the reaction The kettle starts to heat up to 48-55°C, and at the same time, adjust the stirring speed of the reactor agitator to 180-220r / min, and simultaneously turn on the cobalt salt solution metering pump and the ammonium bicarbonate metering pump, and control the flow rate of cobalt chloride at 250-350L / h, the concentration of the cobalt chloride solution itself is 125-135g / L, the start-up flow rate of ammonium bicarbonate is controlled at 800-1000L / h, by changing the feed flow rate of ammonium bicarbonate, adjust the pH within 2 hours ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com