Method for producing spherical cobaltous carbonate

A production method and technology of cobalt carbonate, applied in the direction of cobalt carbonate, etc., can solve the problems of violent local reaction, uneven distribution of product particles, and no spherical cobalt carbonate can be produced, and achieve the effect of ensuring controllability

Inactive Publication Date: 2009-03-04

周红阳

View PDF0 Cites 15 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0003] The traditional cobalt carbonate production method is to make cobalt chloride and ammonium bicarbonate react under high temperature conditions, which is easy to cause severe local reactions, resulting in excessive particle growth and various shapes (dendritic, flake, rod, etc.) ), coupled with the use of mechanical stirring during the reaction, the crystal structure of the product is easily damaged, and it is impossible to grow uniformly

In addition, the flow, temperature, and pH value control of the traditional process are not constant and accurate

In short, the traditional process is easy to cause uneven particle distribution and inconsistent crystal shape of the product, which is not conducive to the stability of product quality, and spherical cobalt carbonate cannot be produced at all.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

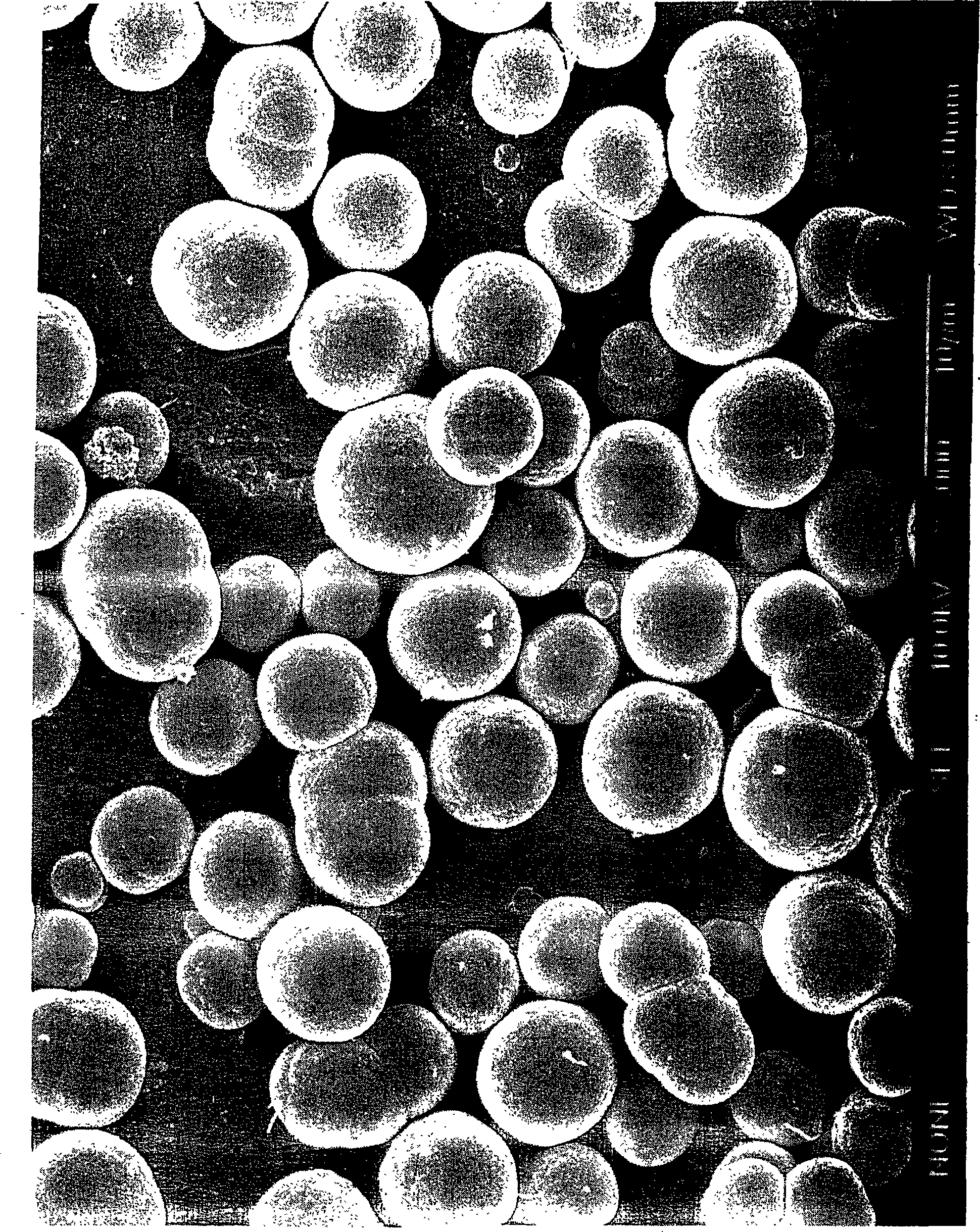

[0024] The embodiment is exactly the same as the production steps of the present invention, and will not be repeated here. image 3 It is the crystal morphology of the spherical cobalt carbonate produced by the present invention.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention relates to a manufacturing method of spherical cobalt carbonate. At first, a cobalt chloride solution and an ammonium hydrocarbonate solution are led to flow into a reaction tank according to a certain flow rate, the reaction temperature is controlled between 5 and 9 DEG C by a refrigerator; the reaction is conducted under the condition that the pH value is 7.2 to 7.3; when the liquid level of a ground-paste reaches 1.5m<3> in the reaction tank, the ground-paste is discharged into an ageing tank, the ground-paste in the ageing tank is heated until the temperature ranges from 43 to 47 DEG C, is processed through standing, precipitation and growth, is filtered, pulped and washed after being aged for 18 hours, and then is dried and secondary-recovered by a cyclone separating device and a pouched trapper to obtain the finished product. The manufacturing method is characterized in that the refrigerator is utilized to reduce the reaction temperature during the reaction process, and a product crystal is led to grow canonically and evenly instead of being influenced by temperature no longer and grow to a spheroid finally under the conditions of constant flow, constant temperature and constant pH value. At the same time, the production mode adopts the standing and ageing without stirring to achieve the determinacy on particle nucleation condition and manufacturing time during the product is manufactured, thereby ensuring the controllability on particle diameter and shape of the precipitate particles.

Description

technical field [0001] A method for producing new materials, particularly a method for producing cobalt carbonate for battery materials, catalysts, magnetic materials, electronic materials, hard alloys and other manufacturing industries. Background technique [0002] In the modern information society, the rapid development of mobile electronic devices benefits from the excellent electrochemical performance of green lithium-ion secondary batteries. Lithium cobalt oxide is the most mature material for the production of cathode materials for lithium ion secondary batteries. The key raw materials that determine the quality of lithium cobalt oxide are not only affected by the density and crystal structure of cobalt carbonate, but also the crystal morphology. At present, the industrial production of spherical cobalt carbonate is still blank in China, so the production of spherical cobalt carbonate is an urgent need of the battery industry. [0003] The traditional production meth...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C01G51/06

Inventor 周红阳

Owner 周红阳

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com