Process for preparing high-density cobaltous carbonate

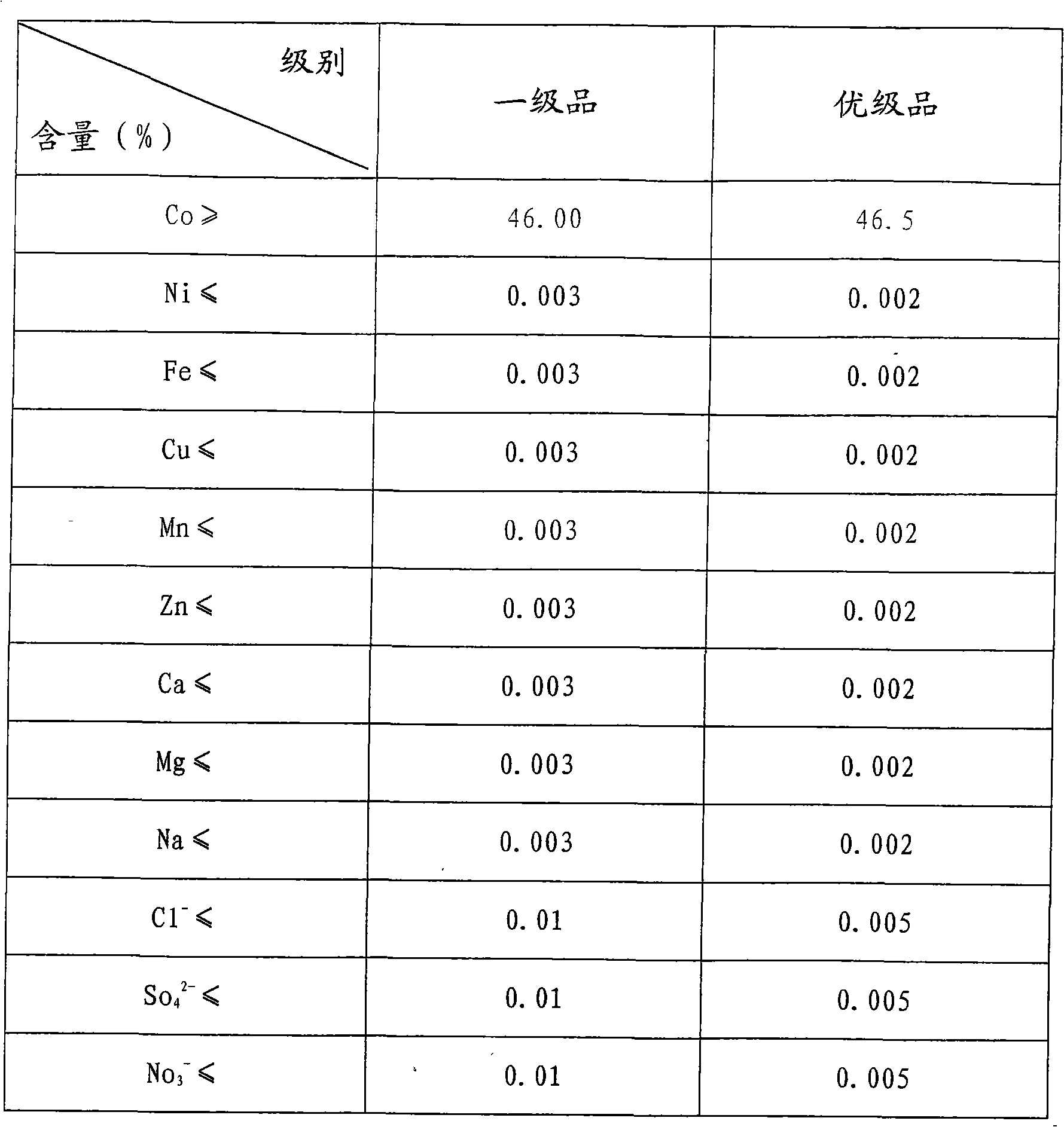

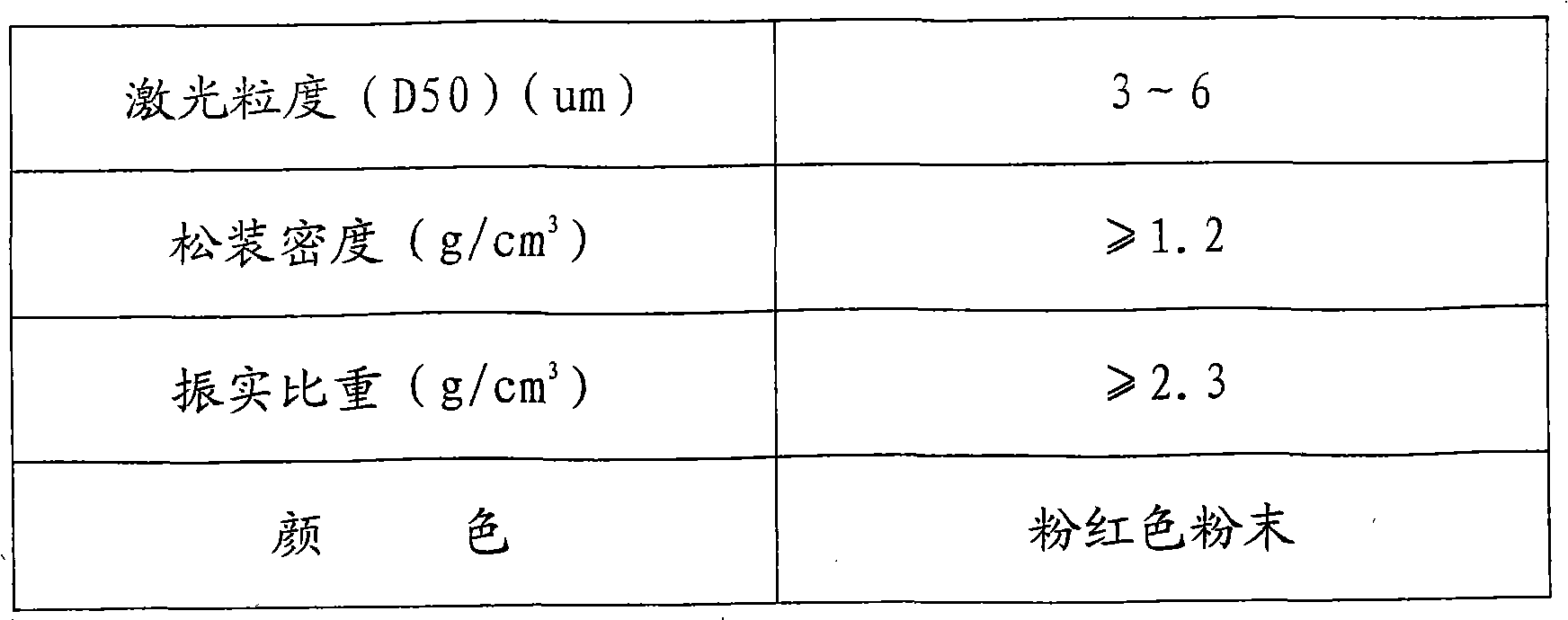

A production method and technology of cobalt carbonate, applied in the direction of cobalt carbonate, etc., can solve the problems of unstable pH value control, uneven distribution of product particles, poor consistency, etc., to ensure controllability, high-density quality and stable consistency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

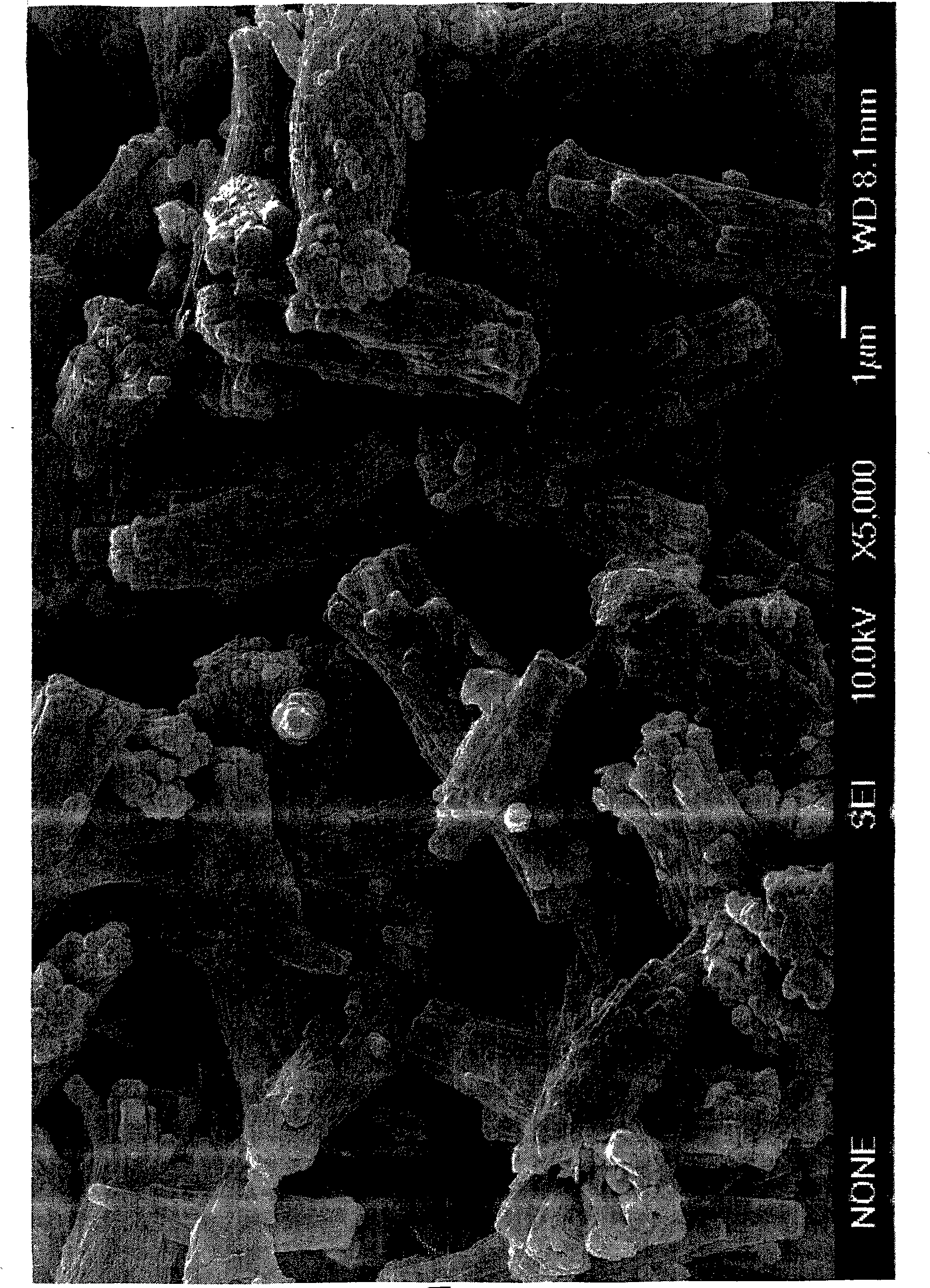

Image

Examples

Embodiment 1

[0025] The production steps are the same as above, and will not be repeated in addition. Cobalt chloride concentration is 87g / L among this example, and ammonium bicarbonate concentration is 175g / L.

Embodiment 2

[0027] Basically the same as Example 1, the difference is that the concentration of cobalt chloride is 80g / L, and the concentration of ammonium bicarbonate is 160g / L.

Embodiment 3

[0029] Basically the same as Example 1, the difference is that the concentration of cobalt chloride is 90g / L, and the concentration of ammonium bicarbonate is 180g / L.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com