Production equipment and technique for ultramicro powder of cobalt carbonate

A technology of cobalt carbonate powder and production equipment, applied in the direction of cobalt carbonate, etc., can solve the problems of difficult adjustment of temperature and pH value, low production efficiency, difficult specific surface area, etc., and achieve the effect of stable product quality and improved production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

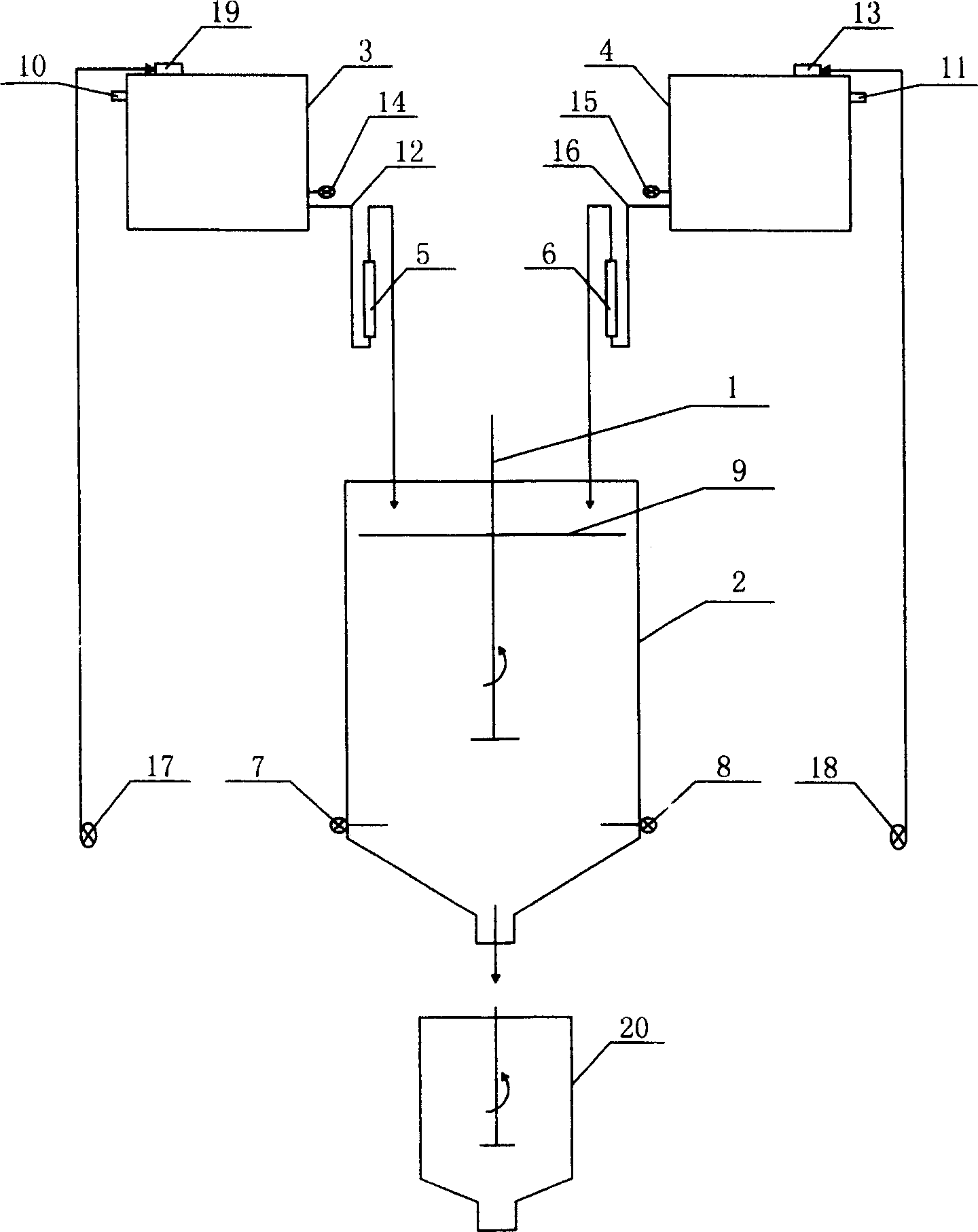

Method used

Image

Examples

Embodiment 1

[0020] When CoCl 2 Contains Co 2+ 70g / l, NH 4 ·HCO 3 Concentration 20wt%, adding speed: cobalt salt solution 60L / min, precipitant 180L / min; precipitation reaction temperature 40°C: pH value 7.0; stirring speed 700r / min (frequency conversion speed regulation); adjust feed amount = generate CoCO 3 The discharge of the precipitated solution keeps the liquid level of the reactor stable at 50 cm below the sieve plate; the aging time is 1.5 hours.

[0021] Get CoCO 3 Fine powder, particle size D 50 = 0.65 μm.

Embodiment 2

[0023] When CoCl 2 Contains Co 2+ 40g / l, NH 4 ·HCO 3 Concentration 20wt%, other conditions are with embodiment 1.

[0024] Get CoCO 3 Fine powder, particle size D 50 = 3.16 μm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com