Preparation method of small-particle size spherical cobalt carbonate

A technology of cobalt carbonate and small particle size, applied in the direction of cobalt carbonate, etc., can solve the problem of small particle size spherical cobalt carbonate not forming a sphere, etc., and achieve the effect of easy promotion and low process cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0026] The embodiment of the present invention provides a method for preparing spherical cobalt carbonate with small particle size, which specifically includes the following steps:

[0027] Step 1, cobalt salt and ammonium bicarbonate solution are added to the reactor to react, and the pH value of the reaction process is controlled so that the pH value of the system is adjusted to 7.0 ± 0.1 after half an hour; the cobalt salt is cobalt chloride, cobalt sulfate, acetic acid A kind of cobalt, the concentration of cobalt salt is 60-160g / l, the flow rate is 1-5L / h; adjust according to the flow rate of ammonium bicarbonate; the concentration of ammonium bicarbonate is 120-240g / l;

[0028] Step 2, continue to add cobalt salt and ammonium bicarbonate solution in parallel, keep the pH value of step 1 unchanged, and precipitate after 2 hours of reaction; the reaction temperature is 35-65°C, and the stirring rate is 50-220r / min;

[0029] Step 3, performing solid-liquid separation and dr...

Embodiment 1

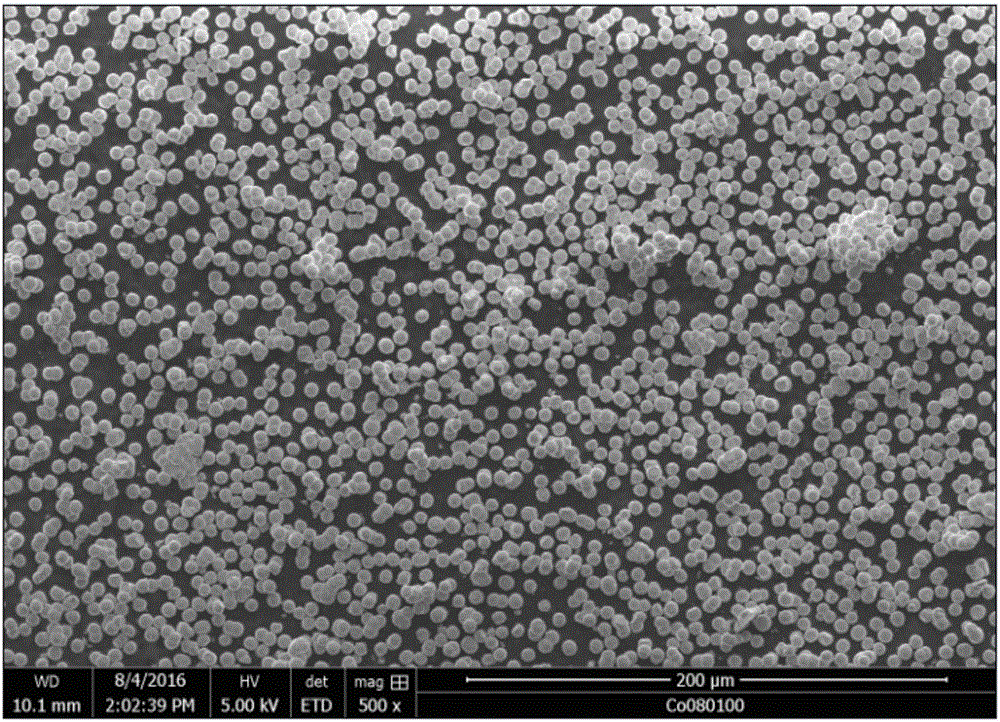

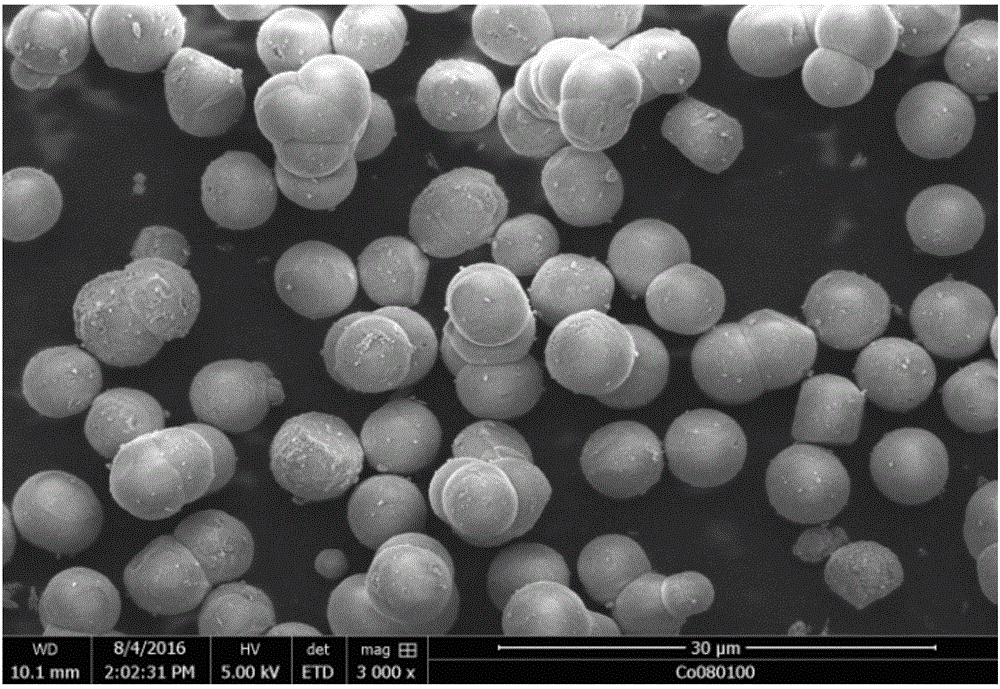

[0032] Concentration is the cobalt chloride of 120g / l and the ammonium bicarbonate mixing reaction that concentration is 220g / l, and wherein the flow of cobalt chloride is 2.5L / h, and the flow of regulating ammonium bicarbonate in the reaction process makes the mixed solution after half an hour The pH value is 7.015, keep the pH value unchanged and continue to show, stir at 40°C at a speed of 150r / min, react for 2 hours and then precipitate, then separate the solid-liquid and dry the precipitated solution to obtain a small particle size Spherical cobalt carbonate, such as figure 1 and figure 2 shown. Among them, the laser particle size analyzer test D 10 18.572 μm, D 50 34.967μm, D 90 It is 50.655μm, and the size of the secondary particle electron microscope is between 3-5μm, which may be caused by the agglomeration of small spherical particles during the laser particle size test.

Embodiment 2

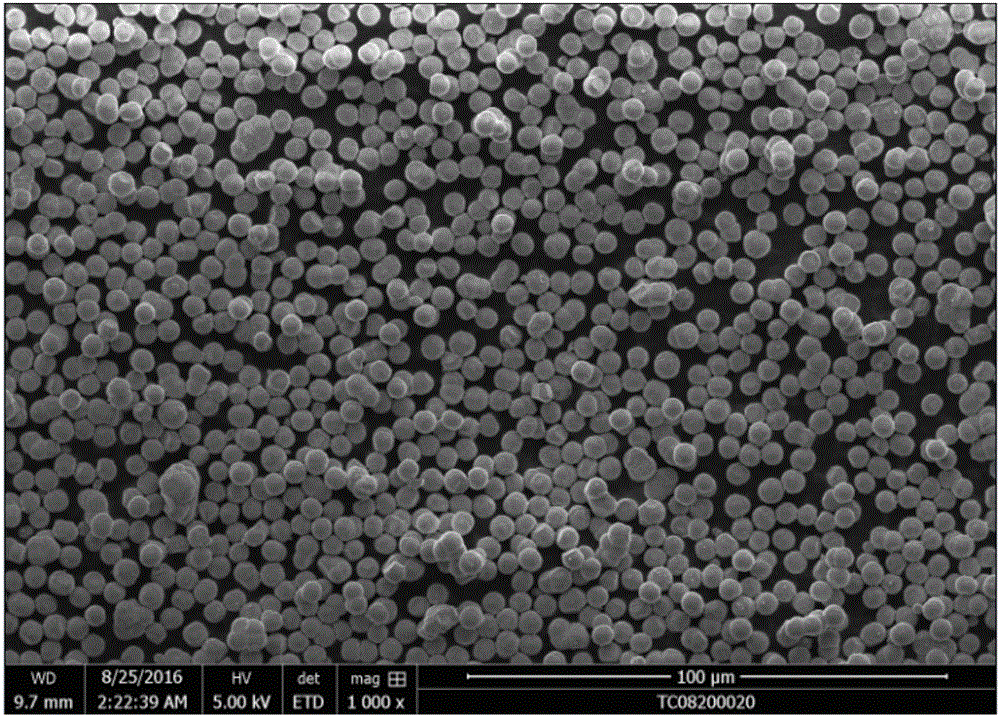

[0034] Mix the cobalt chloride with a concentration of 60g / l and the ammonium bicarbonate with a concentration of 120g / l, wherein the flow rate of cobalt chloride is 1L / h, adjust the flow rate of ammonium bicarbonate during the reaction so that the pH value of the mixed solution after half an hour It is 7.002, keep the pH value unchanged and continue the reaction, stir at 35°C at a speed of 220r / min, precipitate after 2 hours of reaction, and then separate solid-liquid and dry the precipitated solution to obtain spherical carbonic acid with small particle size Cobalt, such as image 3 and Figure 4 shown. Among them, the laser particle size analyzer test D 10 9.582 μm, D 50 23.616 μm, D 90 It is 44.681μm, and the size of the secondary particle electron microscope is between 3-5μm, which may be caused by the agglomeration of small spherical particles during the laser particle size test.

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com