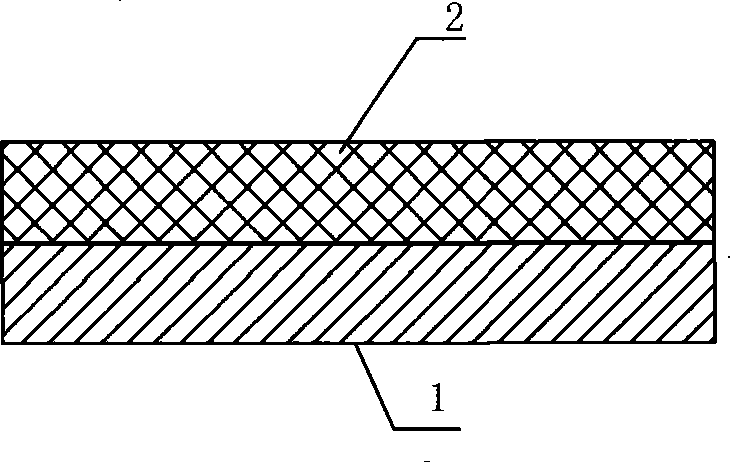

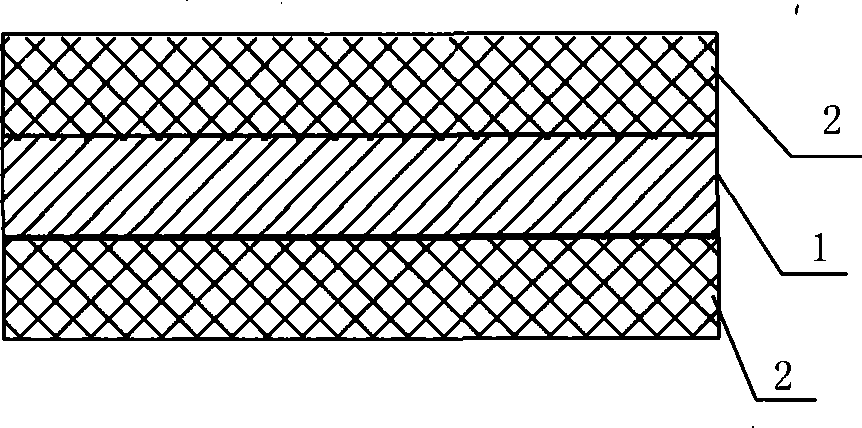

Composite water-proof coil stock of rubber and producing method thereof

A waterproof membrane and production method technology, applied in the direction of rubber layered products, chemical instruments and methods, layered products, etc., can solve the problems of low production efficiency and low service life, achieve high production efficiency, long service life, reduce The effect of production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

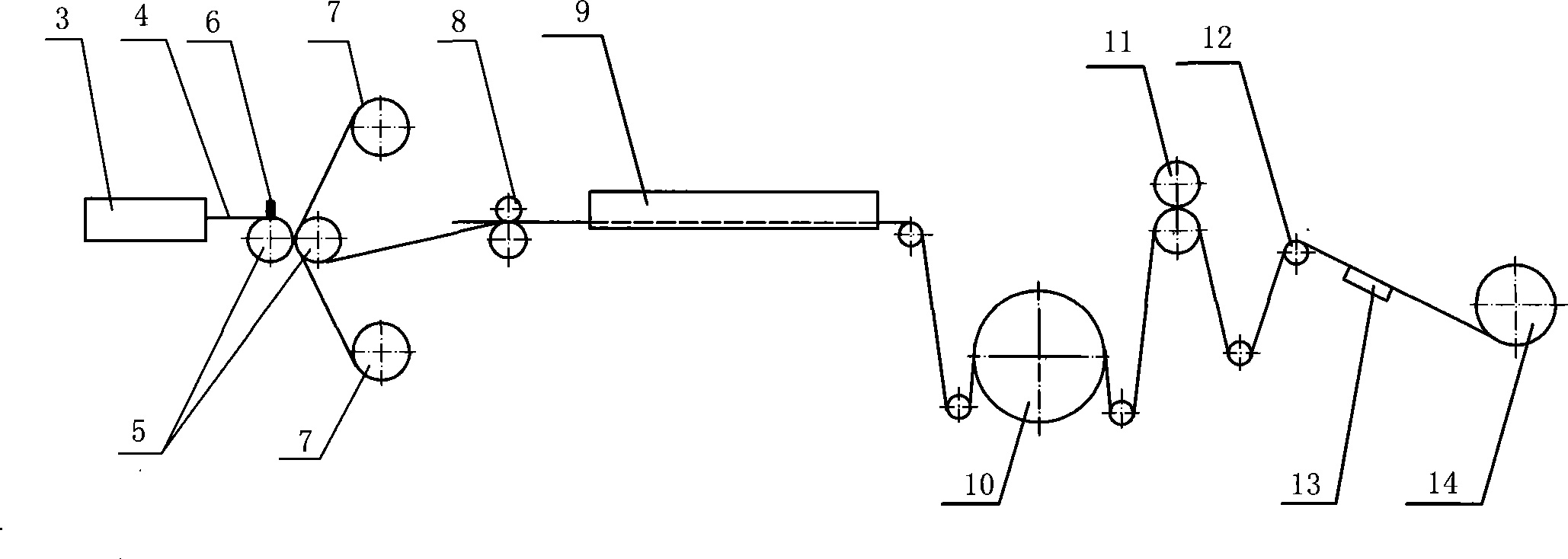

Method used

Image

Examples

Embodiment 1

[0042] 100 parts of EPDM rubber;

[0044] 2 parts stearic acid;

[0045] 3 parts of polyethylene glycol;

[0046] 1.5 parts of paraffin;

[0047] Extrude 80 parts of carbon black quickly;

[0048] 30 parts of calcium carbonate;

[0049] 60 parts of plasticizer;

[0050] Accelerator BZ 0.8 parts;

[0051] Accelerator CZ 2 parts;

[0052] Accelerator TMTD 0.5 parts;

[0053] 2 parts of sulfur;

[0054] The plasticizer in this embodiment selects paraffin oil (paraffin oil).

[0055] Utilize the rubber of above-mentioned component ratio to produce the method for rubber composite waterproof coiled material as follows:

[0056] 1. For rubber mixing, the components of the above raw materials are put into the internal mixer according to the weight percentage for mixing, the mixing temperature is controlled at 100°C, and the mixing time is 4 minutes;

[0057] 2. Mix and discharge the material and send it to the open mill for heat dissipation, ...

Embodiment 2

[0063] 100 parts of EPDM rubber;

[0064] 30 parts of chlorinated polyethylene;

[0066] 1 part stearic acid;

[0067] 1.5 parts of polyethylene glycol;

[0068] 4 parts paraffin;

[0069] Quickly extrude 60 parts of carbon black;

[0070] 40 parts of superfine talcum powder;

[0071] 80 parts of plasticizer;

[0072] Accelerator BZ 1.0 parts;

[0073] Accelerator CZ 1.5 parts;

[0074] Accelerator TMTD 1.5 parts;

[0075] 3 parts sulfur;

[0076] The plasticizer in this embodiment selects paraffin oil (paraffin oil).

[0077] The production method of this embodiment is the same as that of Embodiment 1, and is omitted.

Embodiment 3

[0079] 100 parts of EPDM rubber;

[0080] 25 parts of butyl rubber;

[0081] 10 parts of zinc oxide;

[0082] 3 parts stearic acid;

[0083] 2 parts of polyethylene glycol;

[0084] 1 part paraffin;

[0085] Quickly extrude 60 parts of carbon black;

[0086] 50 parts of calcium carbonate;

[0087] 50 parts of plasticizer;

[0088] Accelerator BZ 0.5 parts;

[0089] Accelerator CZ 3 parts;

[0090] Accelerator TMTD 1 part;

[0091] 1 part sulfur;

[0092] The plasticizer in this embodiment selects paraffin oil (paraffin oil).

[0093] The production method of this embodiment is the same as that of Embodiment 1, and is omitted.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com