Termite-resistant cable sheath polyamide composition, cable sheath, production method and use

A polyamide composition, aliphatic polyamide technology, applied in the sheathing of cables and optical fiber cables, termite resistance, single-layer or multi-layer cable sheathing, can solve the problems of expensive materials and shortage of production, Easy to process, easy to extrude

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 2 approach

[0119] According to a second embodiment of the invention, the polyamide composition comprises at least one organic antioxidant (A1).

[0120] The organic antioxidant (A1) may be selected from those previously defined. Preferred organic antioxidants (A1) are selected from hindered phenolic antioxidants.

[0121] The polyamide composition according to the invention may comprise as a second antioxidant at least one antioxidant (A2) which is different from the antioxidant (A1 ) and which is preferably selected from organic antioxidants. Organic antioxidants (A2) may be selected from organic phosphites, organic phosphonites and / or thio antioxidants. Preferred organic antioxidants (A2) are selected from organic phosphites and organic phosphonites.

[0122] As organophosphites or organophosphinites that can be used in the polyamide composition of the invention, mention may be made of 4,4'-biphenylene diphosphonite tetrakis(2,4-di-tert- Butylphenyl) ester ( P-EPQ), triphenylphosp...

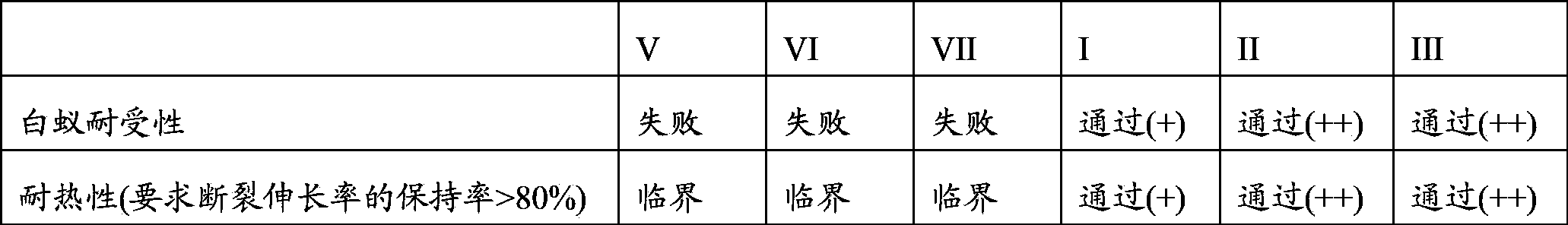

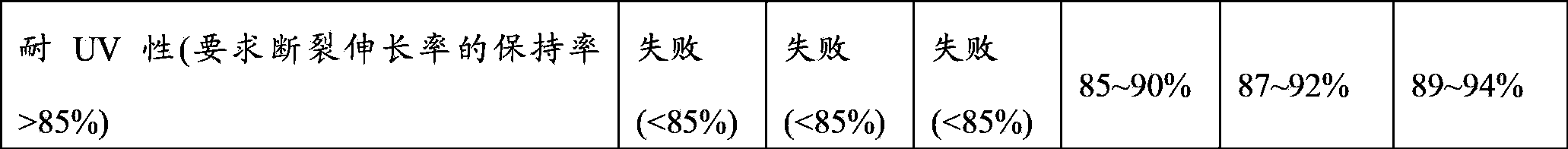

Embodiment

[0209] The polyamide compositions described below have been prepared by melt blending the different ingredients and then extruding into films or tubes depending on the testing purpose. In the extruder, extrusion was performed at a screw speed of 40 revolutions per minute (rpm) with barrel temperatures varying from 180°C to 245°C. Appropriate dies are used to obtain films or tubes.

[0210] The amounts in the table below are given in weight percent relative to the total weight of the polyamide composition.

[0211] Polyamide composition according to the invention

I

II

III

IV

PA10.10

q.s.100

-

-

-

PA10.12

-

q.s.100

-

q.s.100

PA12.12

-

-

q.s.100

-

-

-

2

Green Masterbatch

-

-

6

-

blue masterbatch

3

5

-

-

ADK Stab PEP-36

0.2

0.1

0.3

-

Lowinox 44B25

0.2

0.1

0.4

-...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com