Floor mop

a technology for mop and floor, applied in carpet cleaners, cleaning machines, cleaning equipment, etc., can solve the problem of requiring a lower water level for a complete immersion of the mop in the cleaning water

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

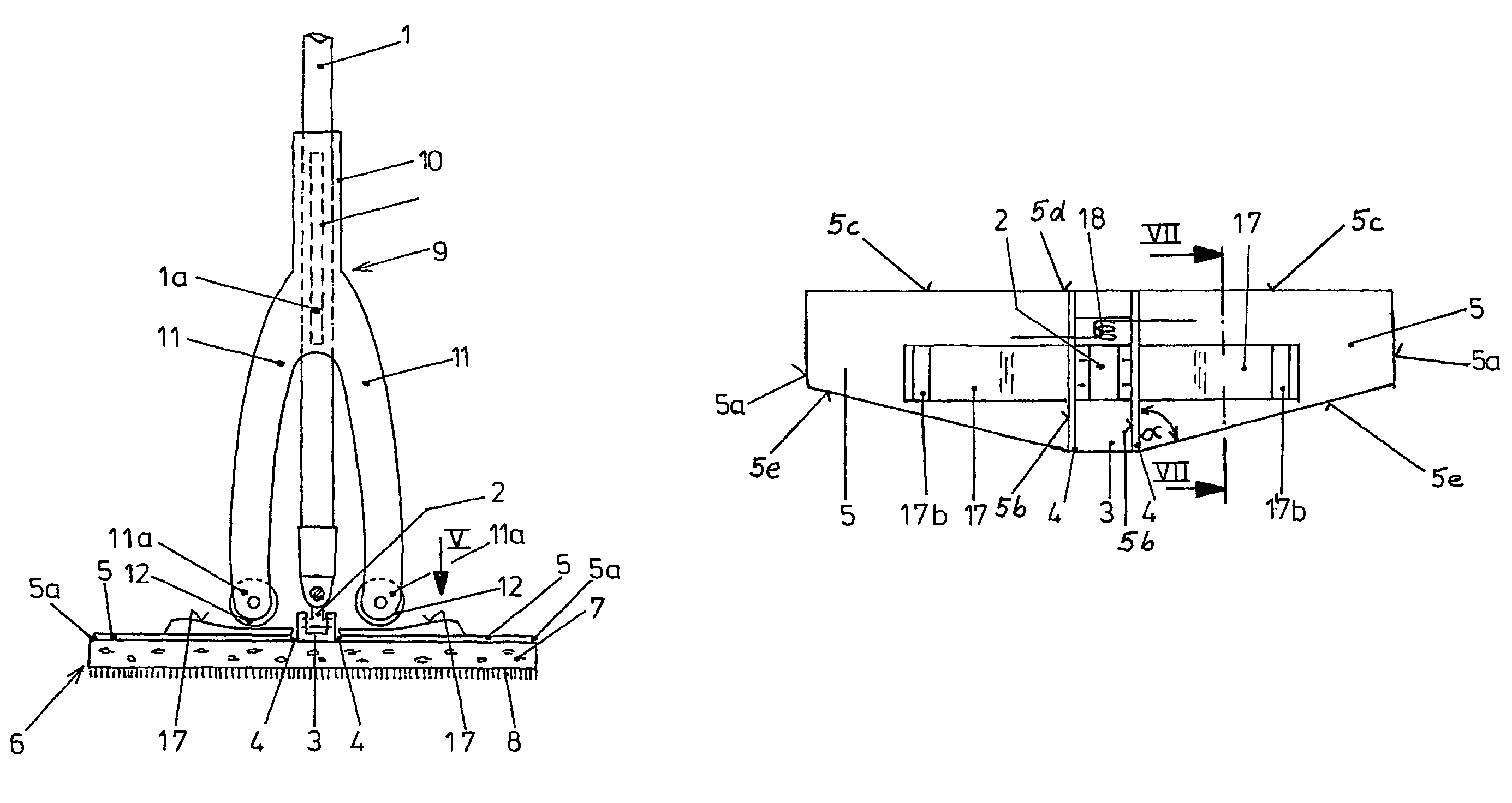

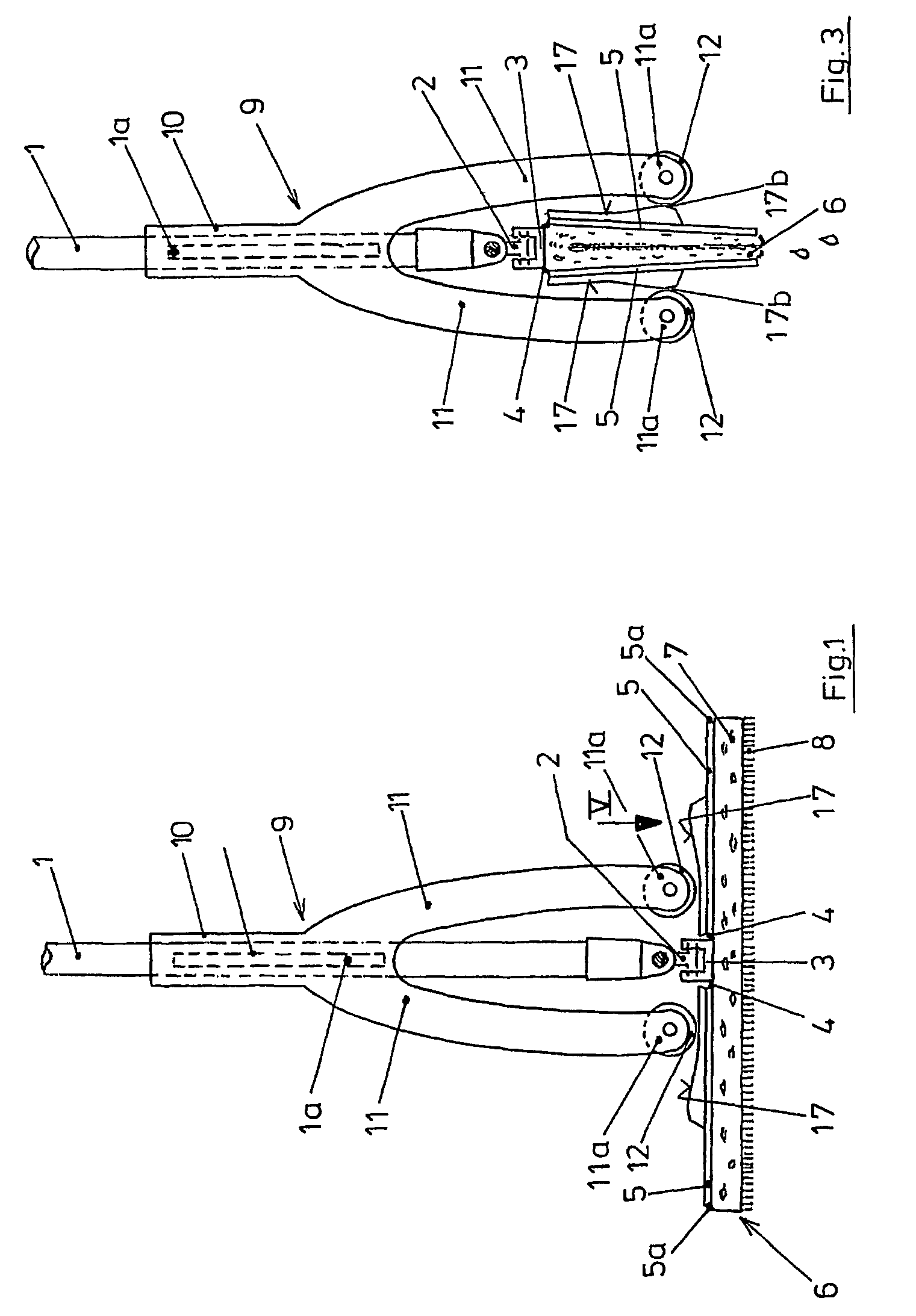

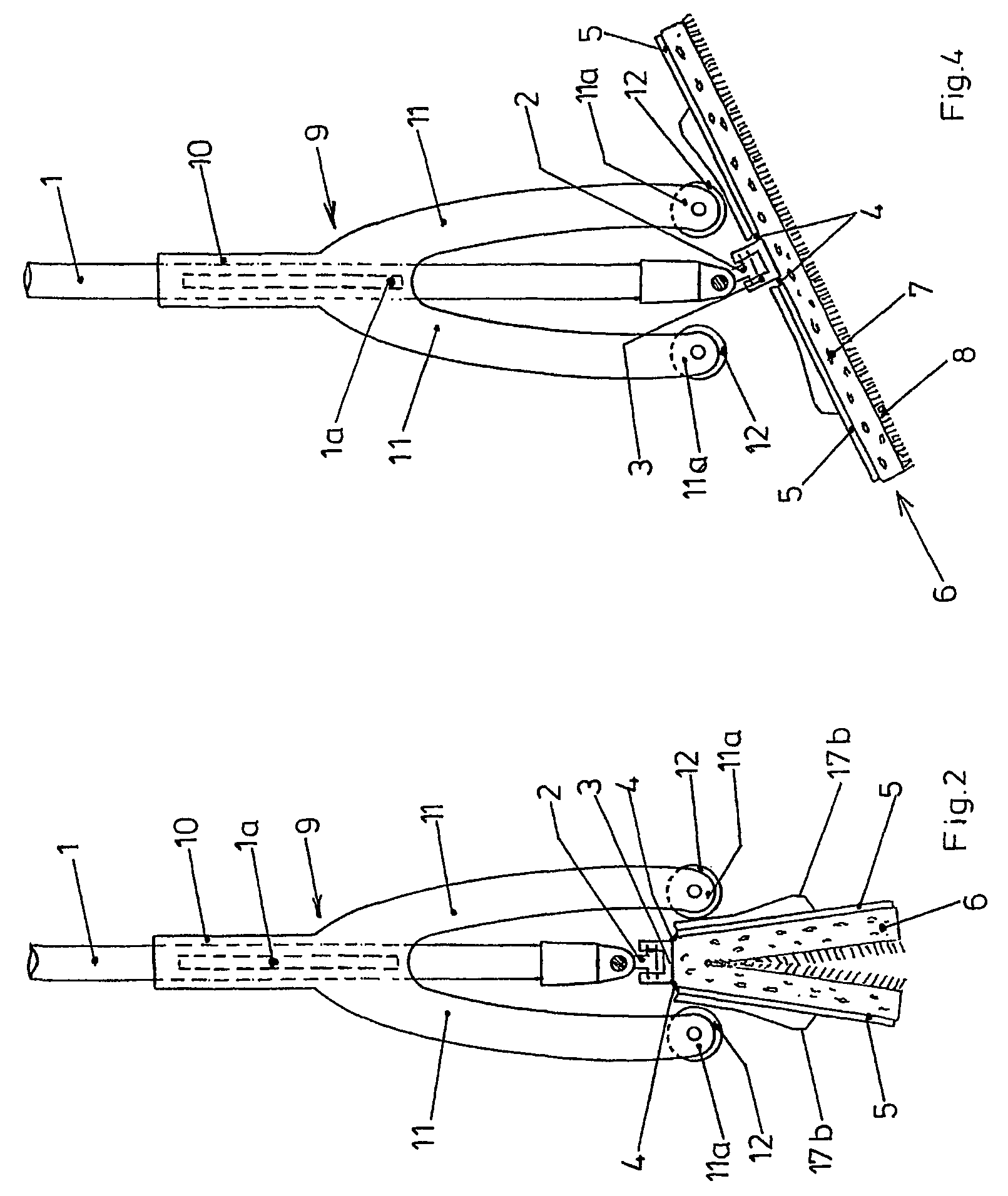

[0031]The floor mop shown in FIGS. 1-5 has a mop handle 1 which is connected via a Cardan joint 2 to a supporting centerpiece 3 non-rotatably but pivotally in all directions. The supporting centerpiece 3 is connected via hinges 4 attached on both sides to a mop supporting wing 5.

[0032]The two mop supporting wings 5 and the supporting centerpiece 3 carry an absorbent, squeezable mop layer 6 which in the conventional fashion consists of a sponge layer 7 and a gauze coating 8.

[0033]A squeezing slider 9 is displaceable along the mop handle 1. The squeezing slider 9 has a guide sleeve 10 which is guided non-rotatably, longitudinally displaceably along the mop handle 1. For example, in the hole of the sleeve 10 there is provided a longitudinal groove into which a pin 1 a attached to the mop handle 1 engages.

[0034]The sleeve 10 is rigidly connected to two squeezing arms 11 which each carry a rotatably supported roller 12 as rotatable rollers at their ends 11a in the exemplary embodiment sh...

PUM

| Property | Measurement | Unit |

|---|---|---|

| circumference | aaaaa | aaaaa |

| convex pressure | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com