Component for vehicle interiors, in particular roof handle

a technology for roof handles and components, applied in the field of vehicle interior components, can solve the problems of metal springs that have a tendency to generate unwanted noise during operation, change the behavior of metal springs, and different characteristics of handles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

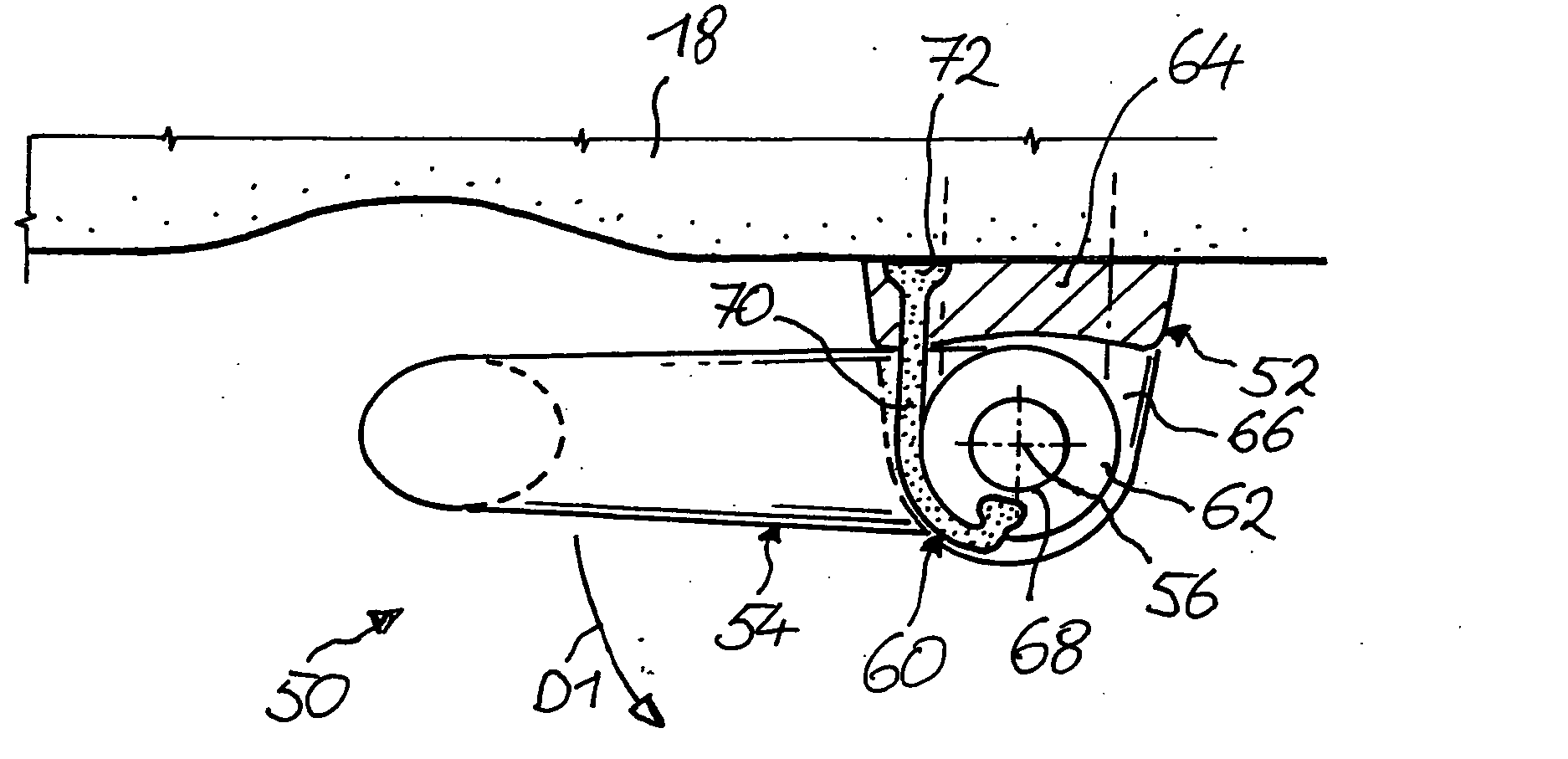

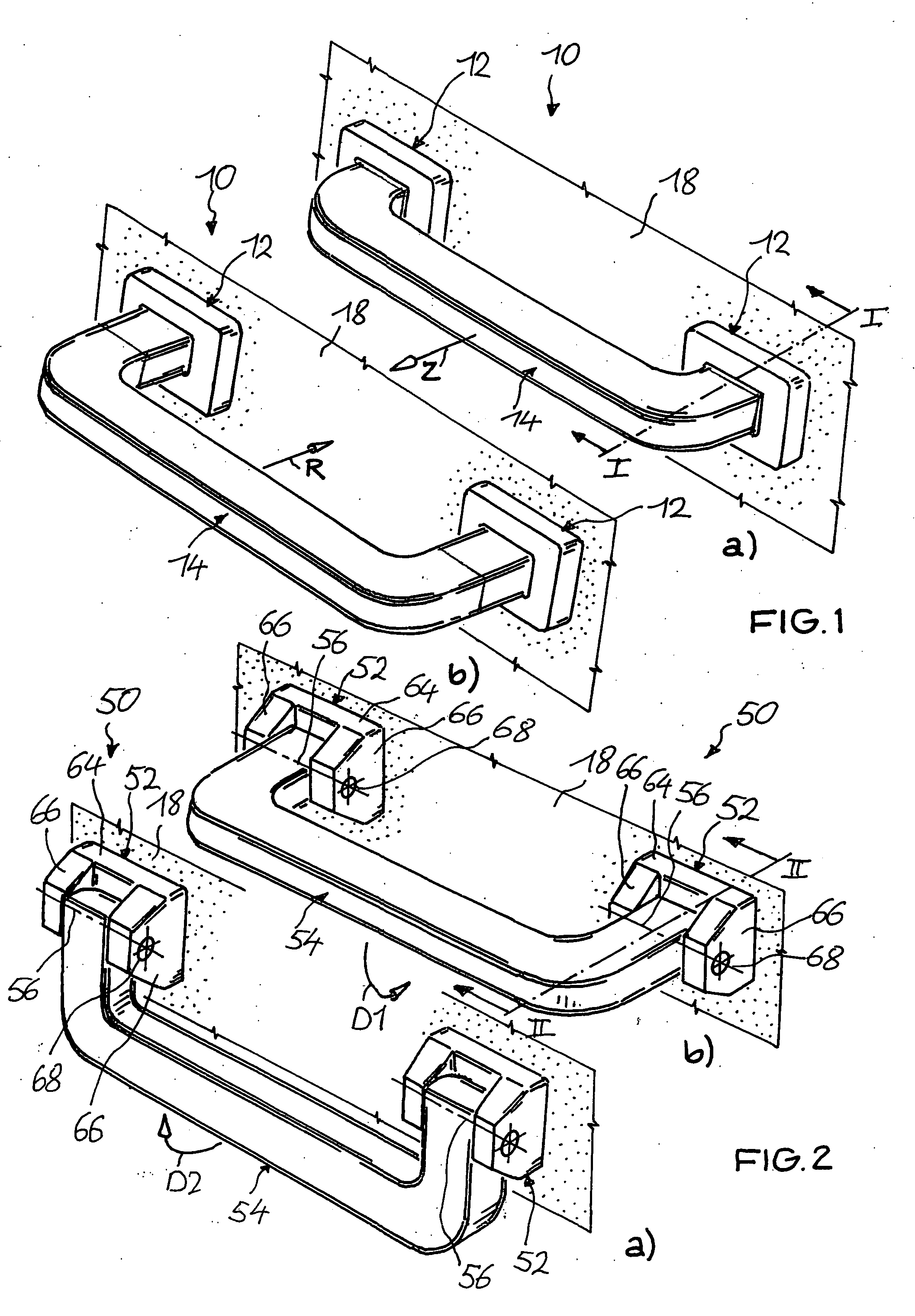

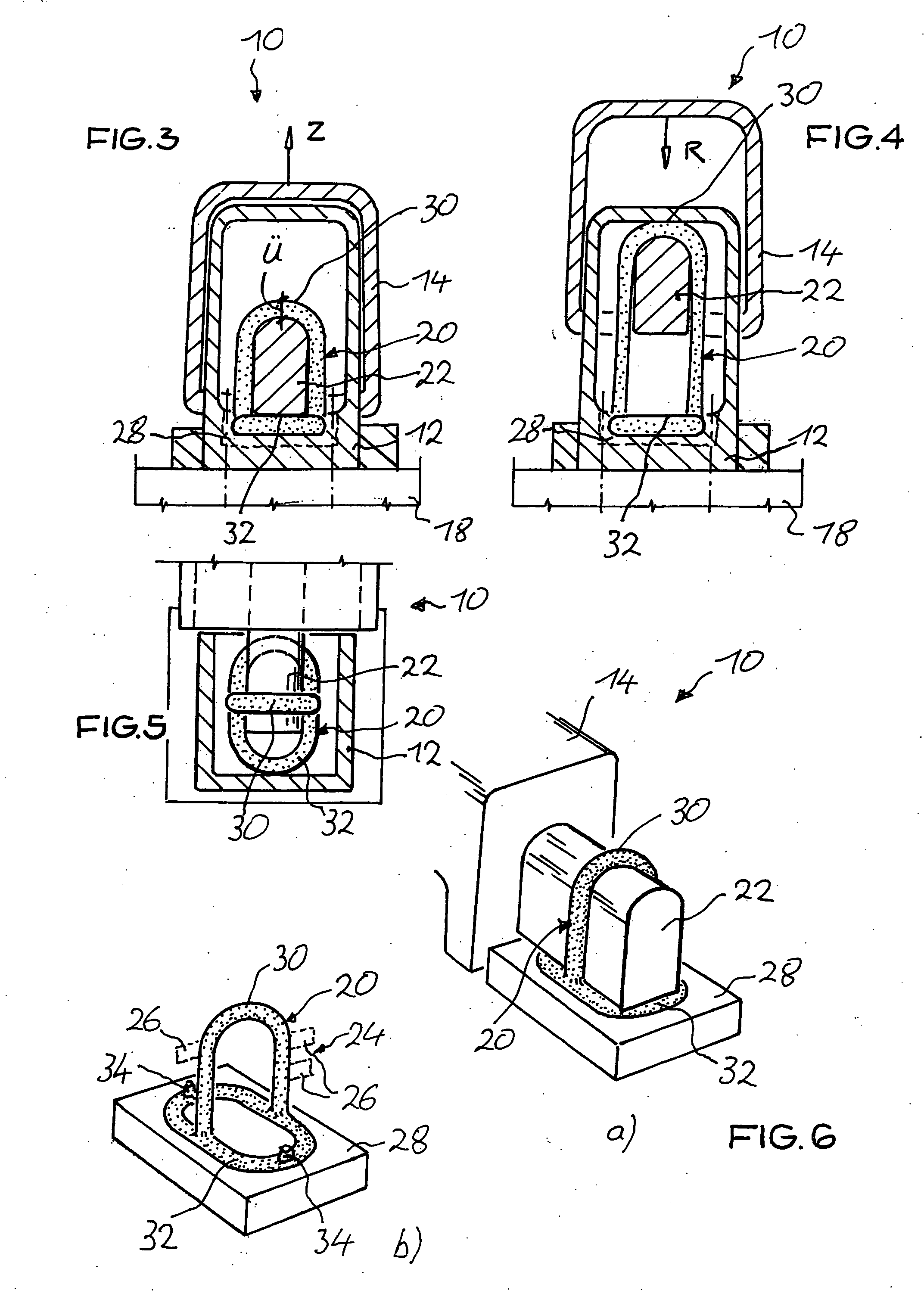

[0038]FIGS. 1a and b shows a component 10, which takes the form of a roof handle 10 for vehicle interiors, the roof handle 10 being configured as a so-called “pull handle”, which can be brought manually from a rest position (FIG. 1a) into a position of use (FIG. 1b).

[0039] The roof handle 10 has a first fixed assembly 12, which takes the form of a bearing unit 12 and which in the assembled state is fixed to the wall 18 of a vehicle interior. Attached to the bearing unit 12 is a second assembly 14, which is displaceable in a translational movement basically perpendicular to the wall 18 and which takes the form of a stirrup handle 14. The two end areas of the U-shaped stirrup handle 14 are attached to corresponding bearing units 12 at both sides. Elastic elements, which will be further described below, act on the stirrup handle 14 in the area of the bearing unit 12. In using the roof handle 10, the stirrup handle 14 is first gripped in the resting position according to FIG. 1a and is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com