Device and method for manufacturing glass fibre reinforced nylon 66 heat-insulating strips

A glass fiber and production device technology, which is applied in the field of glass fiber reinforced nylon 66 heat insulation strip production devices, can solve the problems of serious floating fibers on the surface of the product, the product quality cannot be guaranteed, and the product is easy to form bubbles, etc., and achieves easy recrystallization. , Ensure continuity and stability, and reduce the effect of production processes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

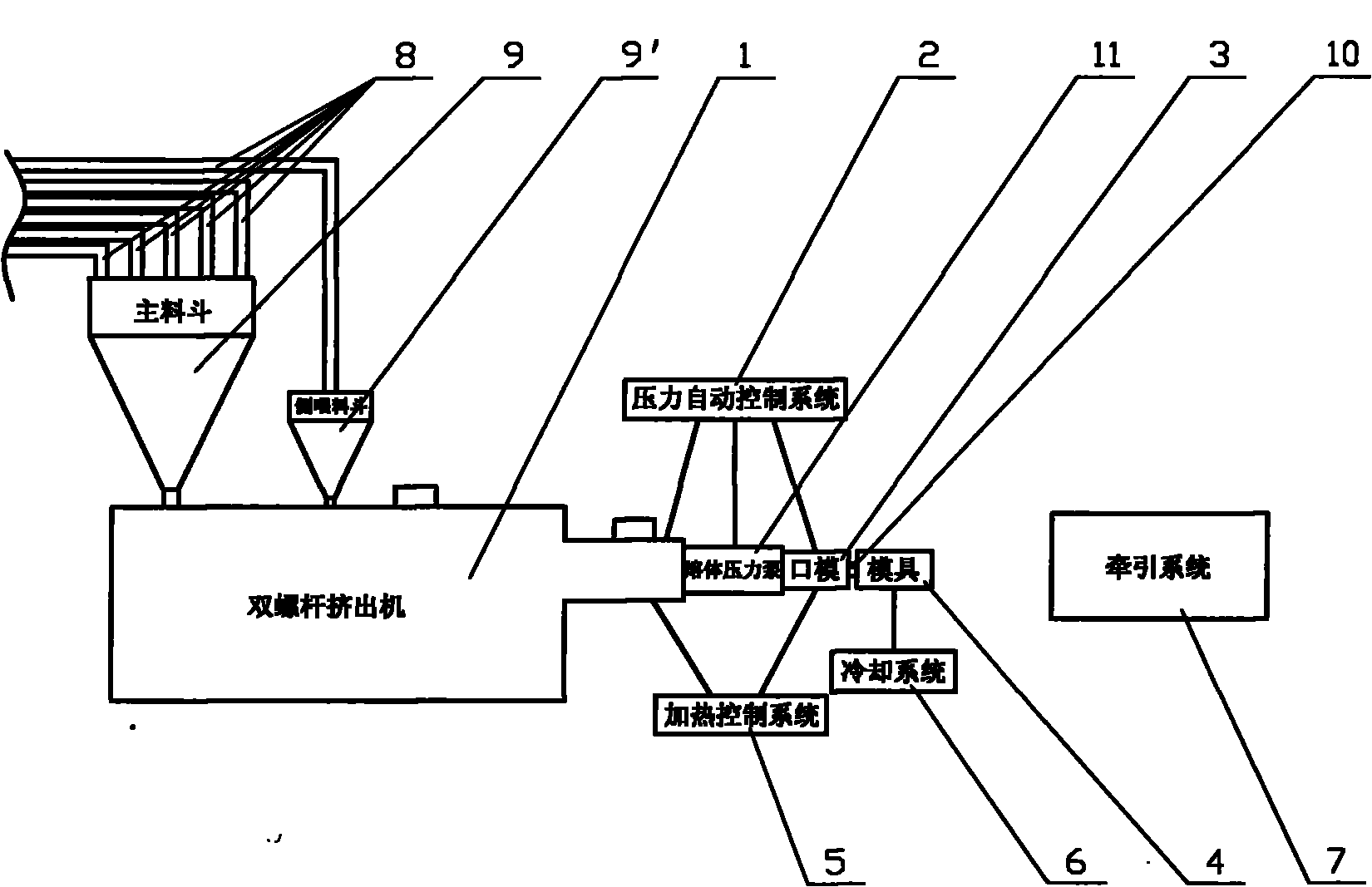

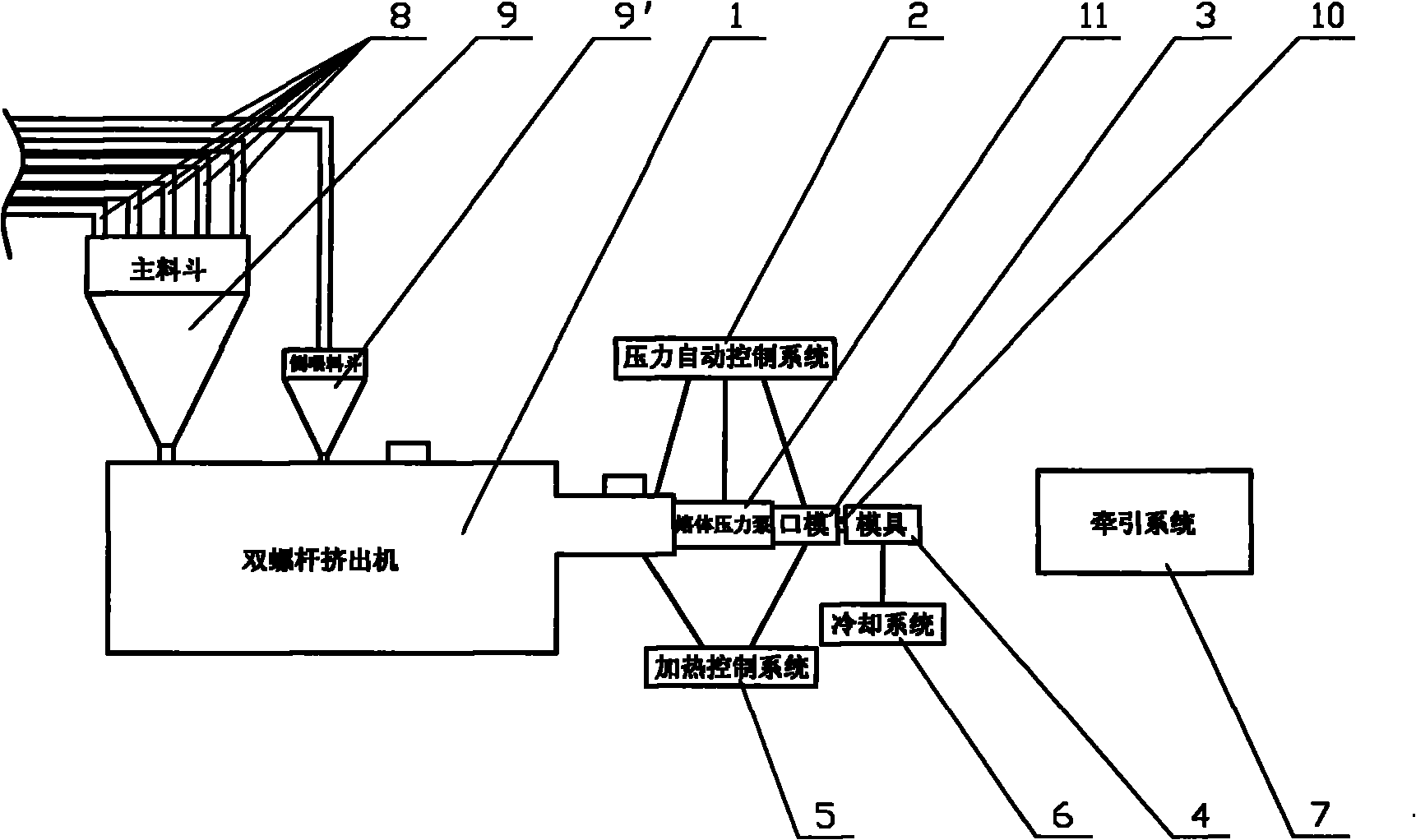

[0026] figure 1 Shown is the embodiment of the production device of glass fiber reinforced nylon 66 heat insulation strips of the present invention, including a feeding system, an extruder 1, a pressure control system 2, a die 3, a shaping die 4, a heating control system 5, and a cooling system 6 and traction system7.

[0027] Such as figure 1 As shown, the feeding system includes a feeding pipeline 8 and a hopper, and each feeding pipeline 8 transports a single component of the raw material to the hopper, and there are two hoppers, a main hopper 9 and a side feeding hopper 9'; then feed Give extruder 1. Extruder 1 is a twin-screw extruder.

[0028] The screw of the twin-screw extruder 1 is made of double-alloy nitrided steel, and the length-to-diameter ratio of the screw is 36-44 to fully plasticize the nylon resin, eliminate glass fiber exposure, and make the temperature distribution of the material more reasonable.

[0029] The shaping die 4 and the mouth die 3 adopt a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com