High-viscosity halogen-free flame-retardant polyamide composition

A technology of flame-retardant polyamide and composition, which is applied in the field of halogen-free flame-retardant, excellent extrusion performance composition, and high viscosity field. The appearance is smooth and black, the color is uniform, and the bending performance is good.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

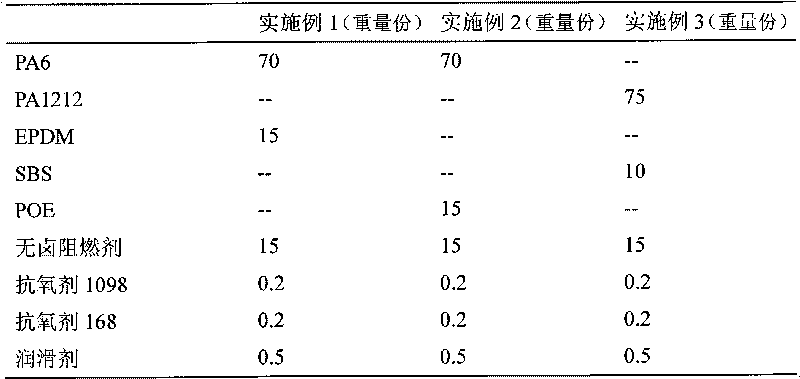

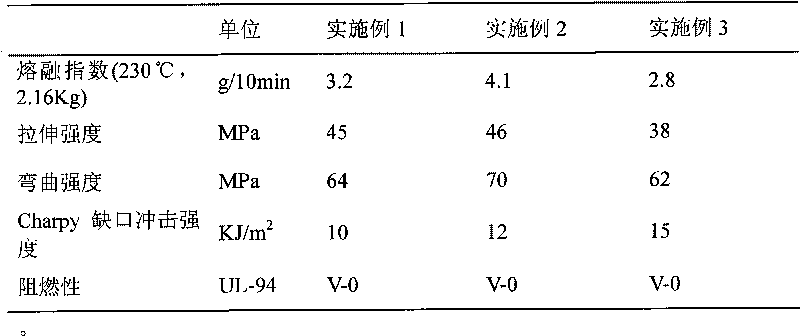

Embodiment 1~3

[0026] In the following examples, PA6 is selected from: the products of Russia Gubixue Flurazide Co., Ltd.;

[0027] PA1212 is selected from: Shandong Dongchen Co., Ltd. products;

[0028] EPDM is selected from: maleic anhydride grafted ethylene-propylene-diene copolymer;

[0029] SBS is selected from: styrene-butadiene-styrene block copolymer grafted with glycidyl acrylate;

[0030] POE is selected from: maleic anhydride grafted ethylene copolymers;

[0031] The halogen-free flame retardant is selected from: melamine cyanurate, a product of Swiss Ciba Specialty Chemicals.

[0032] Antioxidant 1098 is selected from: Irganox 1098 produced by Swiss Ciba Fine Chemicals;

[0033] Antioxidant 168 is selected from: Irganox 168 produced by Swiss Ciba Fine Chemicals;

[0034] The lubricant is selected from: calcium stearate.

[0035] Mix the polyamide resin, toughening agent, halogen-free flame retardant and various additives according to the content in Table 1 at high speed with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com