Normal-temperature dearsenic agent as well as preparation method thereof

A normal temperature, arsenic removal technology, applied in chemical instruments and methods, refining with metal oxides, physical/chemical process catalysts, etc., can solve the problems of low arsenic removal rate, heavy metal pollution, high cost of arsenic removal agent, etc. The effect of removing arsenic efficiency, improving arsenic capacity, and enhancing the effect of arsenic removal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

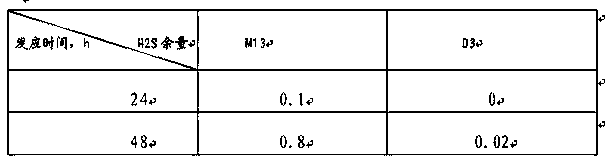

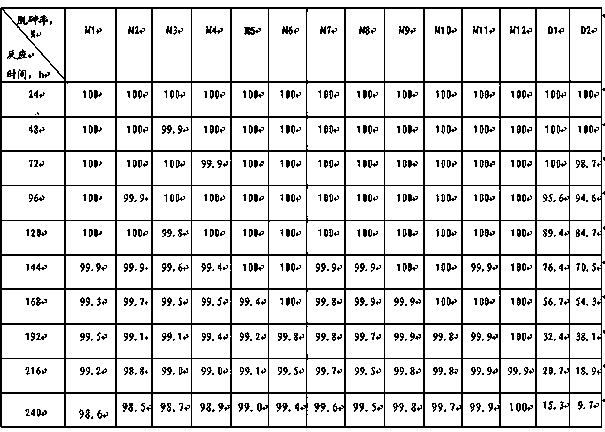

[0033] Grind copper oxide and zinc oxide into powders below 200 microns, weigh 60 grams of manganese ore powder, 10 grams of copper oxide powder, 10 grams of zinc oxide powder, 15 grams of sheep liver soil, 5 grams of scallop powder, and appropriate amount of water, mix Stir together to form a mixture, put the material obtained in the above process into the kneader repeatedly and fully knead evenly, then put it into the extruder, extrude the material into a φ4×2-10mm strip shaped product; place the formed product at 120 After drying at 350-400°C for 3 hours and sintering at 350-400°C for 3-4 hours, the finished product M1 of arsenic removal agent at room temperature was obtained. The performance data of M1 after testing are shown in Table 1.

Embodiment 2

[0035] Grind copper oxide and zinc oxide into powders below 200 microns, weigh 60 grams of manganese ore powder, 5 grams of copper oxide powder, 5 grams of zinc oxide powder, 15 grams of kaolin, 5 grams of cellulose powder, and appropriate amount of water, mix together Stir evenly to form a mixture, put the material obtained in the above process into a kneader repeatedly and knead evenly, then put it into an extruder, extrude the material into a φ4×2-10mm strip molding; place the molding at 120°C Dry for 3 hours, and bake at 350-400°C for 3-4 hours to obtain the finished product M2 of arsenic removal agent at room temperature. The performance data of M2 after testing are shown in Table 1.

Embodiment 3

[0037]Grind copper oxide and zinc oxide into powders below 200 microns, weigh 50 grams of manganese ore powder, 15 grams of copper oxide powder, 15 grams of zinc oxide powder, 15 grams of aluminosilicate cement, 5 grams of cellulose powder, and appropriate amount of water , mixed together and stirred evenly to make a mixture, put the material obtained in the above process into a kneader repeatedly and fully kneaded evenly, then put it into an extruder, and extrude the material into a φ4×2-10mm strip shaped product; put the formed product in Dry at 120°C for 3 hours, and bake at 350-400°C for 3-4 hours to obtain the finished product M3 of arsenic removal agent at room temperature. The performance data of M3 after testing are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com