Patents

Literature

76results about How to "The cooling effect is not easy" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

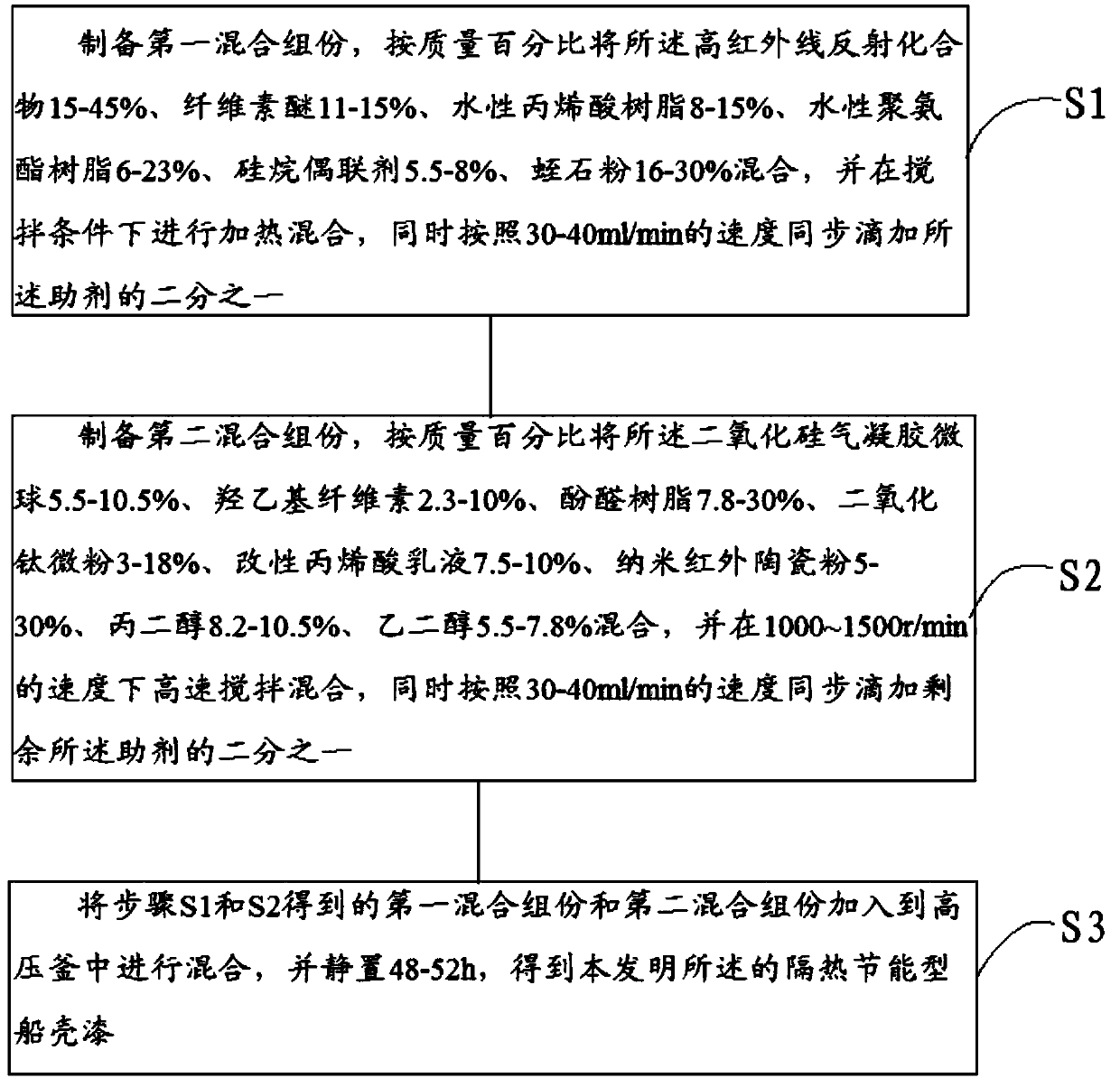

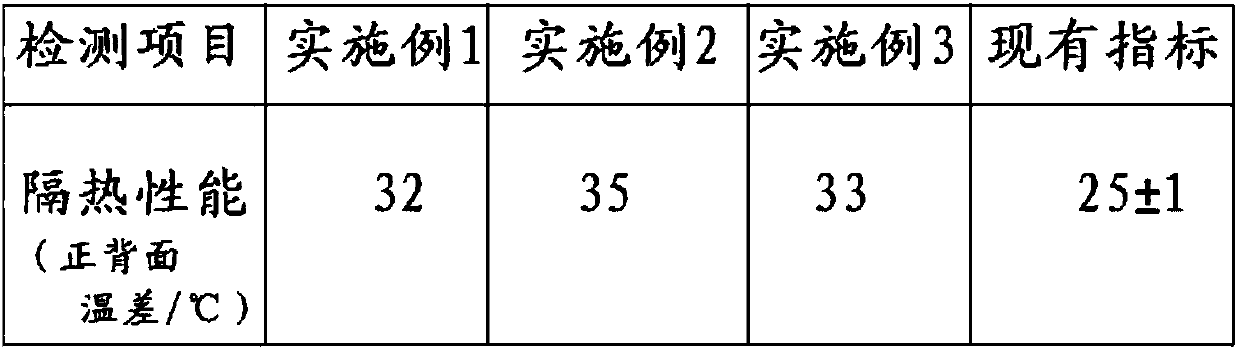

Thermal insulation energy-saving type boat hull paint and preparation method thereof

InactiveCN107556862AImprove heat insulation and energy savingShorten speedPolyurea/polyurethane coatingsReflecting/signal paintsThermal energyCellulose

The invention provides a heat-insulating and energy-saving ship hull paint and a preparation method thereof, wherein the heat-insulating and energy-saving ship hull paint comprises: 15-45% of a high infrared reflection compound and 11-15% of a cellulose ether , water-based acrylic resin 8-15%, water-based polyurethane resin 6-23%, silane coupling agent 5.5-8%, silica airgel microspheres 5.5-10.5%, hydroxyethyl cellulose 2.3-10%, phenolic Resin 7.8-30%, Titanium Dioxide Powder 3-18%, Modified Acrylic Emulsion 7.5-10%, Nano Infrared Ceramic Powder 5-30%, Propylene Glycol 8.2-10.5%, Ethylene Glycol 5.5-7.8%, Vermiculite Powder 16-30% % and auxiliaries 15‑34%. The heat-insulating and energy-saving ship hull paint of the present invention improves the heat-insulating and energy-saving properties of the coating formed after the coating is applied by optimizing the components and the content of the components in the coating, and reduces the speed of heat exchange between the interior and exterior of the hull , so that the internal heat of the ship applying the coating of the present invention is not easy to dissipate heat, which is conducive to energy saving and environmental protection.

Owner:JIANGSU MARINE VICTORY COATING

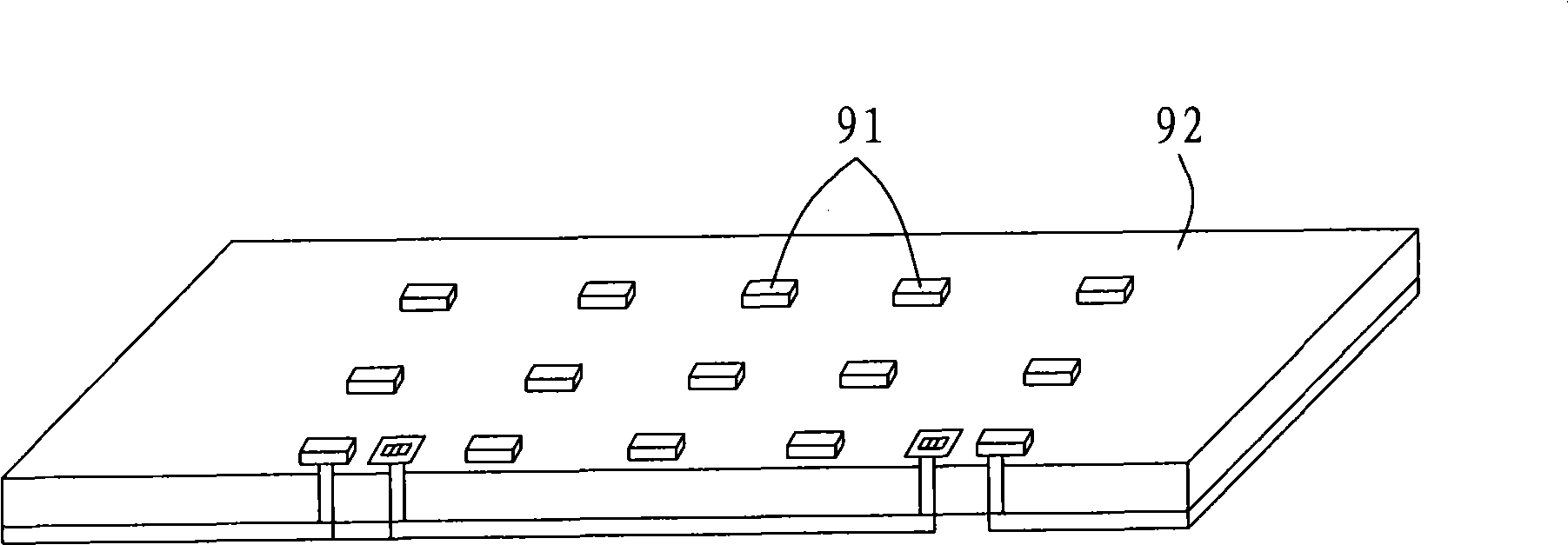

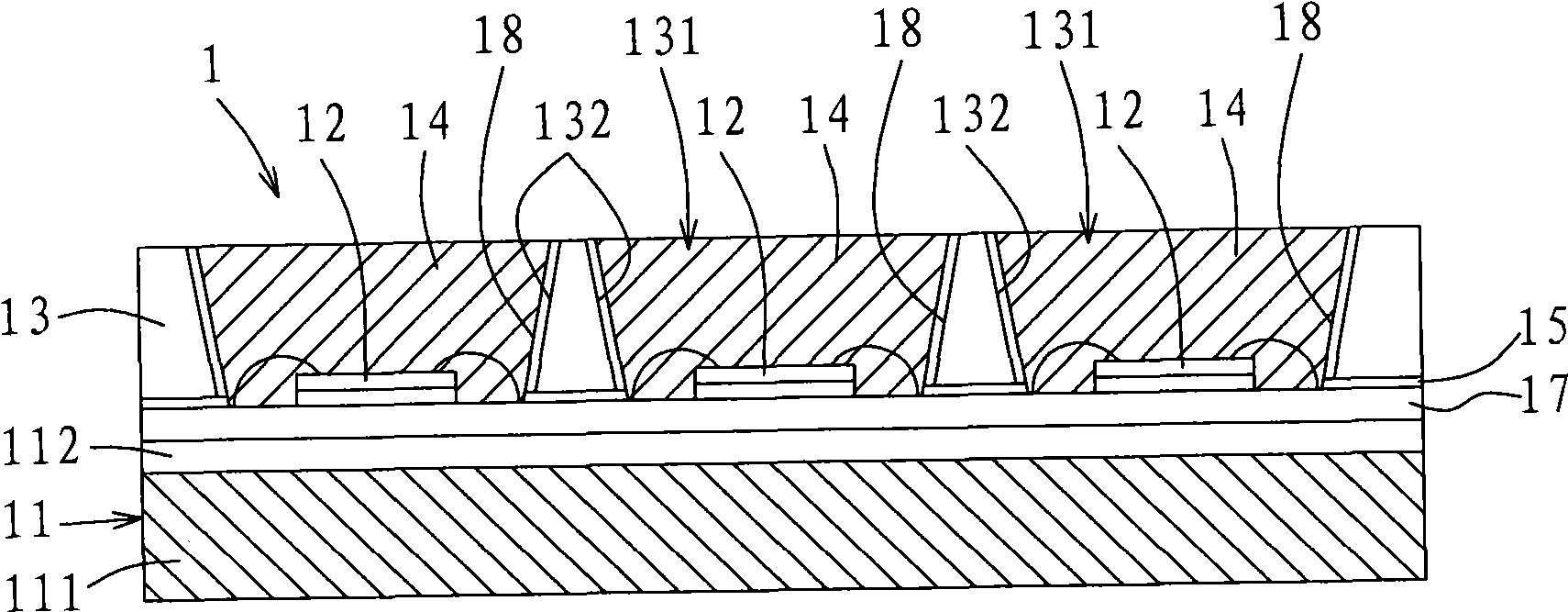

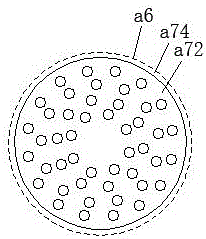

Light emitting diode surface light source device

ActiveCN101545615ABlock out lightOptimize thermal designPlanar light sourcesLighting support devicesLight-emitting diodeLight source

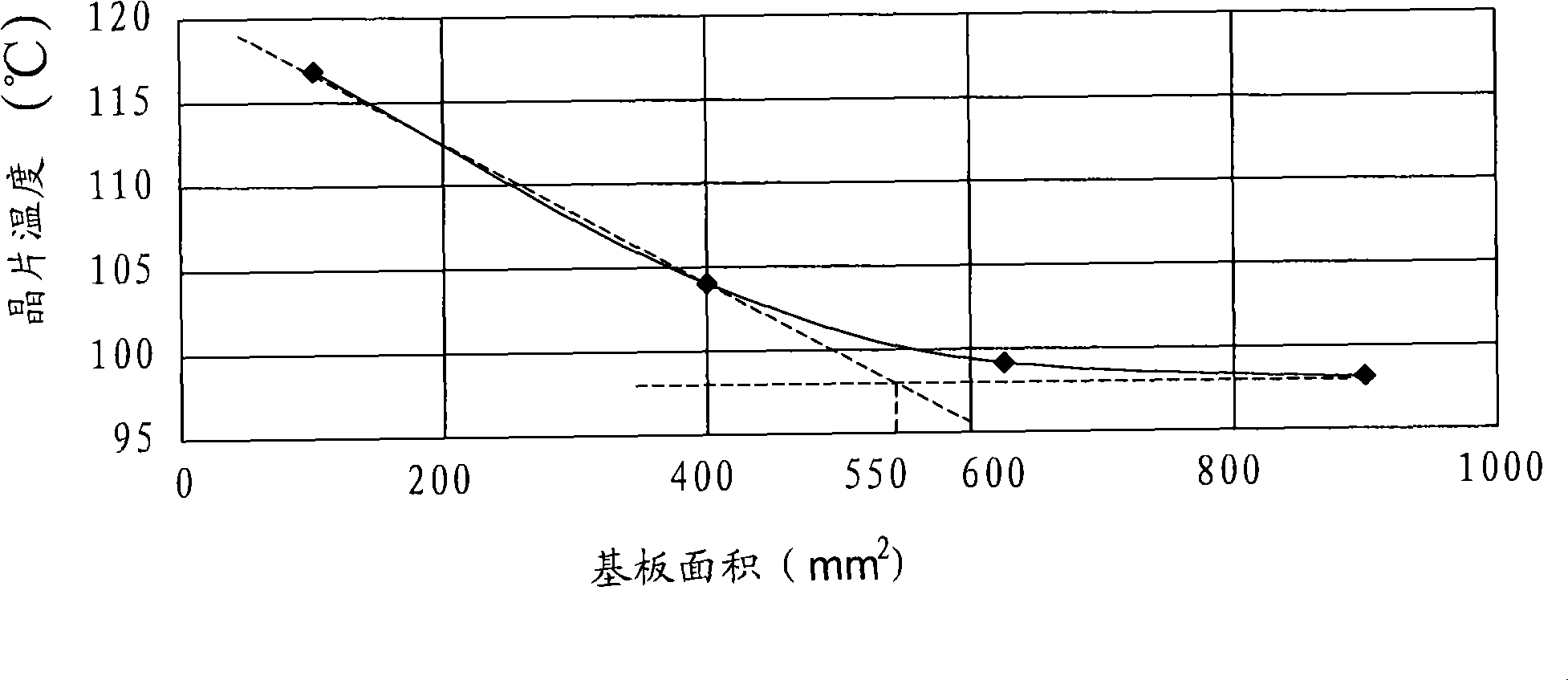

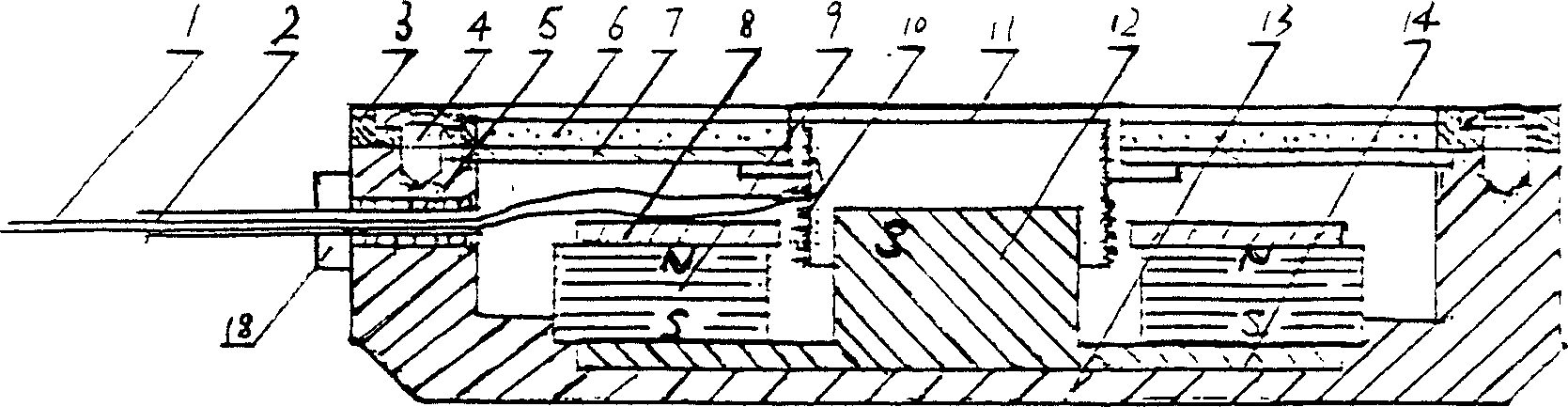

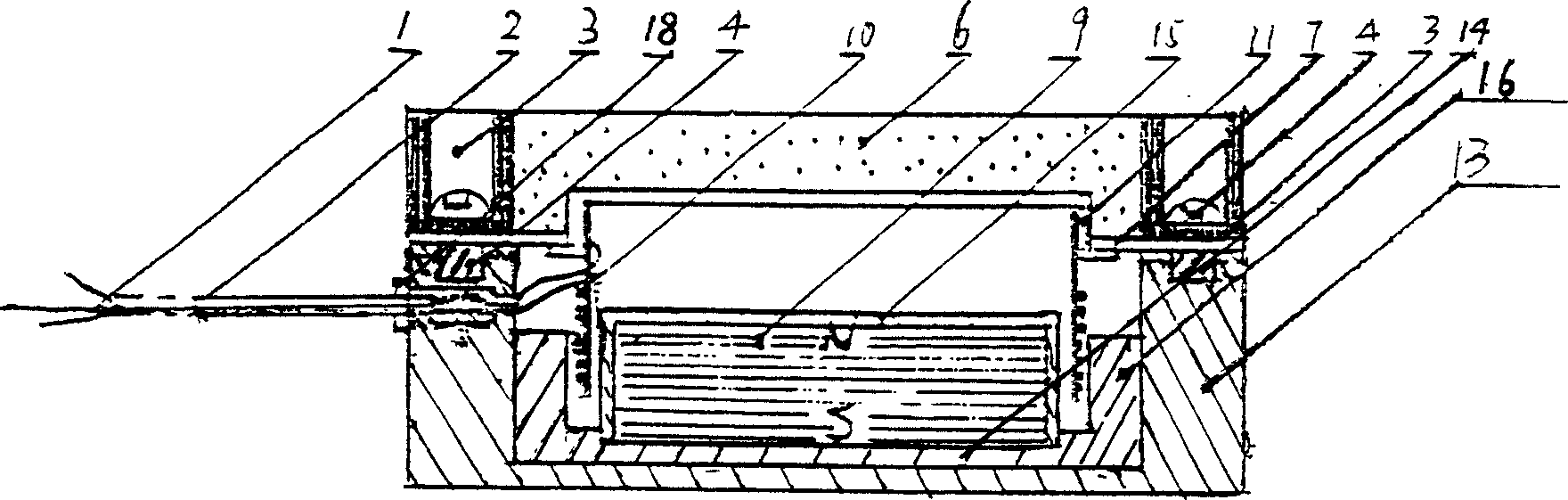

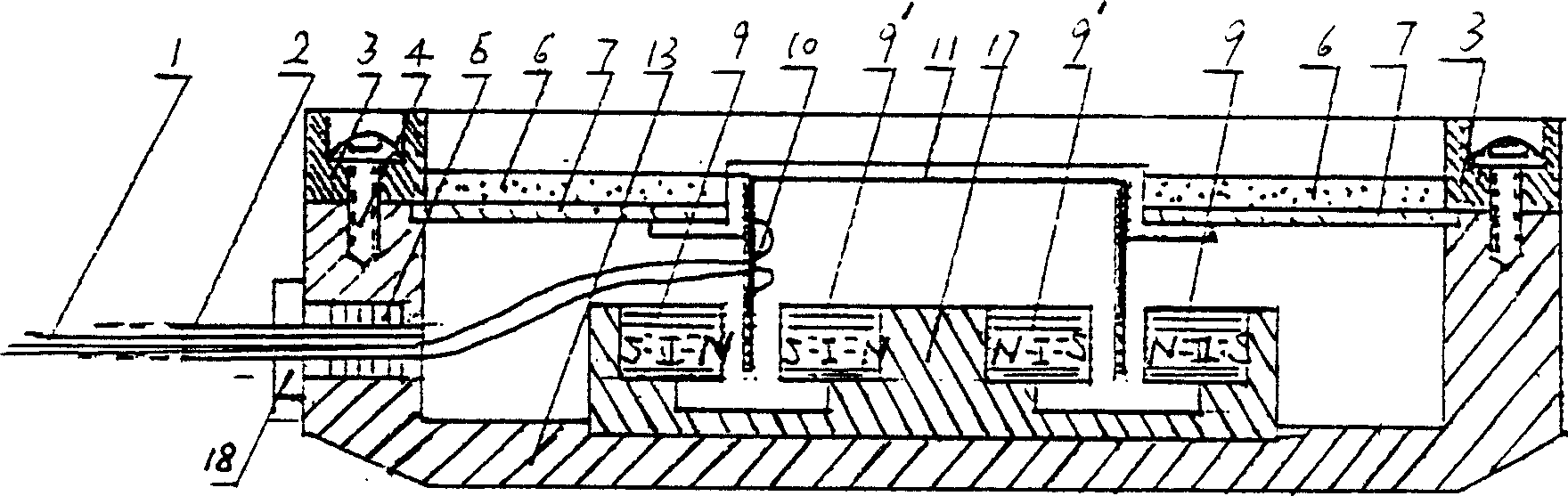

The invention relates to a light emitting diode surface light source device, which comprises a substrate and a plurality of light emitting diode chips arranged on the substrate in array type arrangement. The thickness of the substrate is more than 1 mm. The area of the light emitting diode chip is between 0.08 and 0.25 mm <2>; and the distance between every two light emitting diode chips is more than twice of the dimension of the chip. The light emitting diode surface light source device uses the chip with small dimension and controls the distance between the chips and the thickness of the substrate, can achieve the promotion of luminous efficiency of the whole surface light source device through utilization of the chip with the small dimension, can maintain the temperature of the chip in a lower state, reduce the amplitude needed for radiation and is further favorable for the following radiation design of the whole light emitting diode surface light source device.

Owner:BRIGHT LED ELECTRONICS CORP

Electric water music body-sensing vibration transmitting transducer

InactiveCN1744769AGuaranteed watertightnessOvercome the biggest flaw that cannot be applied in waterTransducers for subaqueous useFluteTransducer

The transducer includes following parts and structure: (1) there is opening for sealing cable on sidewall of the cylindrical shell, and there is flute on inner wall of the shell for placing vibrant plate; magnetic field generator is setup inner bottom surface of the shell; (2) voice coil cover is installed on a matched hole located on middle of the vibrant plate; vibrant plate, voice coil cover and voice coil are pasted together through fire resistant glue; voice coil inside the voice coil cover is extended to magnetic field generator; (3) perforation bolt can be fixed on screw thread of opening for sealing cable; rubber washer is inside the opening so as to seal the exit of cable; (4) the cable is connected to the voice coil; through screw, clasp is fixed on the shell; and through clasp, vibrant plate is fixed on the shell; polyurethane is filled between the vibrant plate and clasp; thus, the vibrant plate and clasp is solidified and sealed.

Owner:INST OF ACOUSTICS CHINESE ACAD OF SCI +1

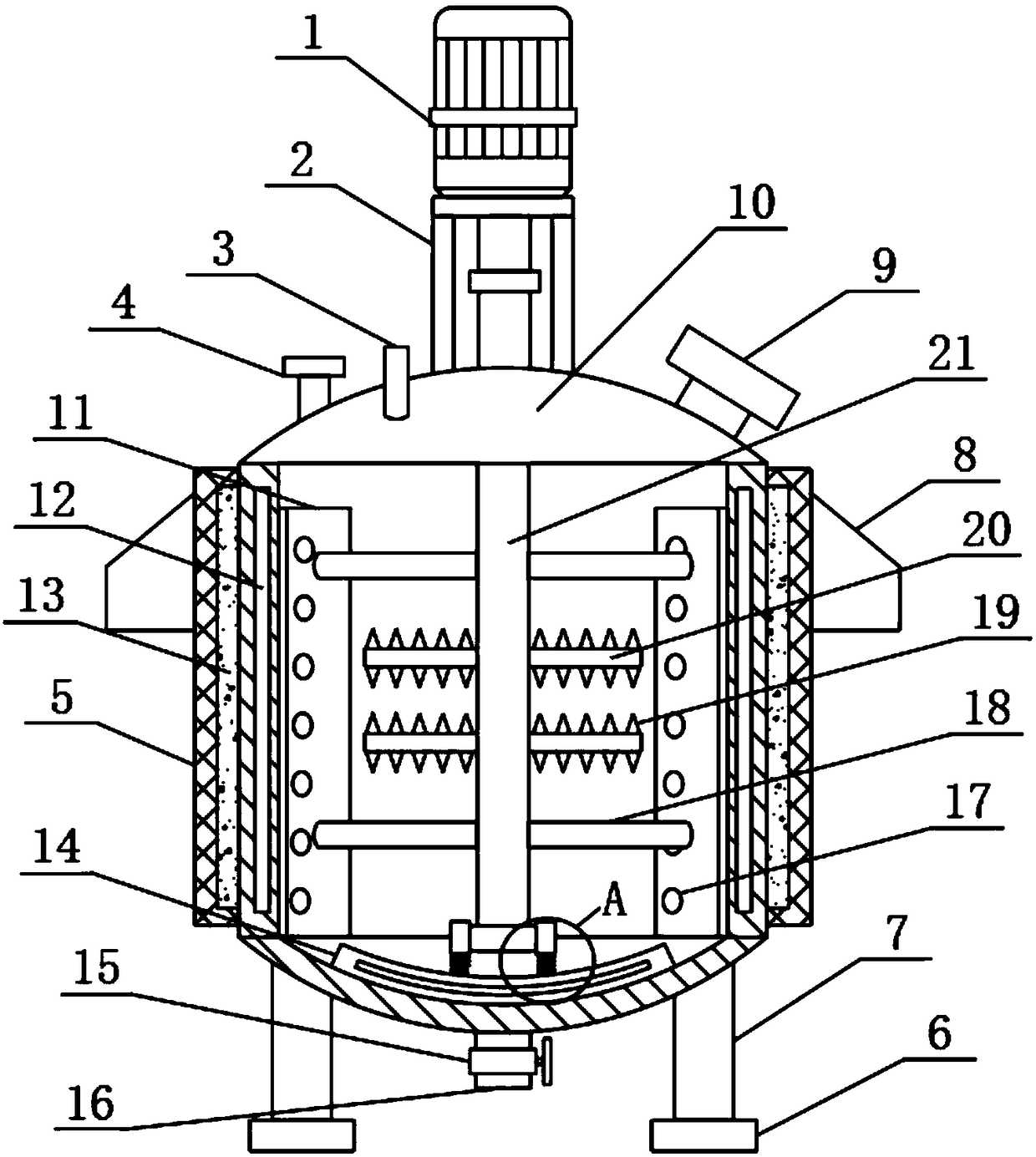

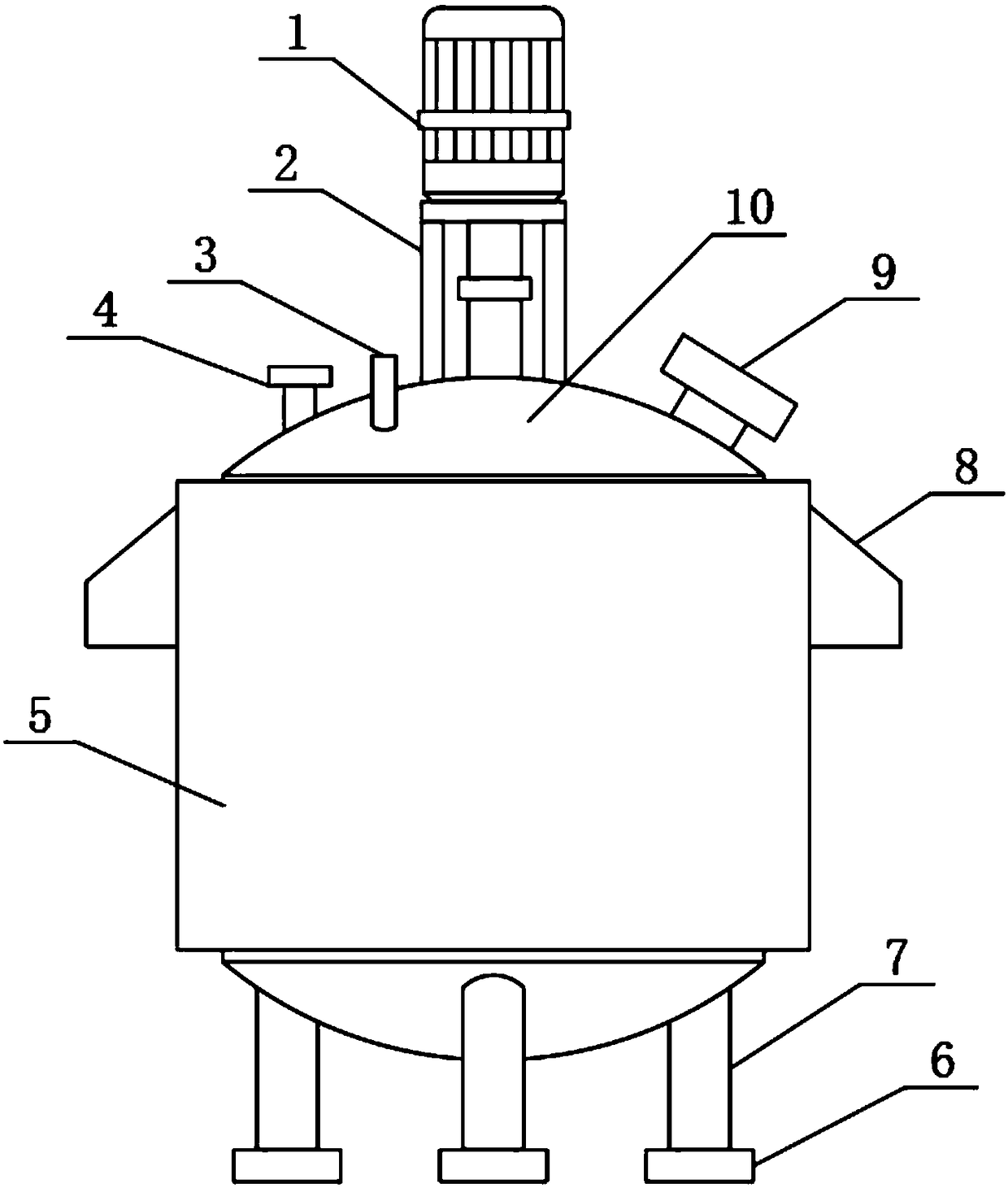

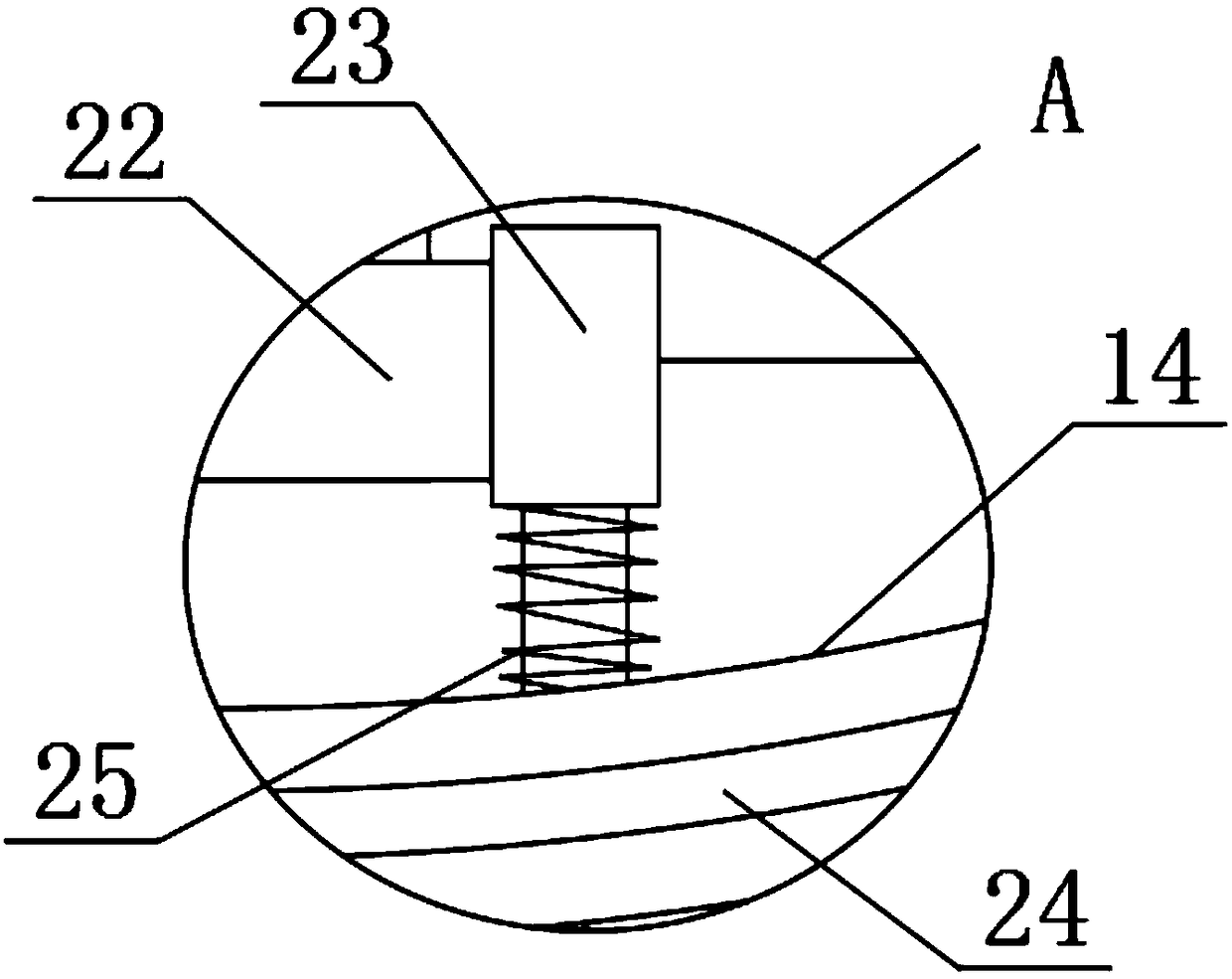

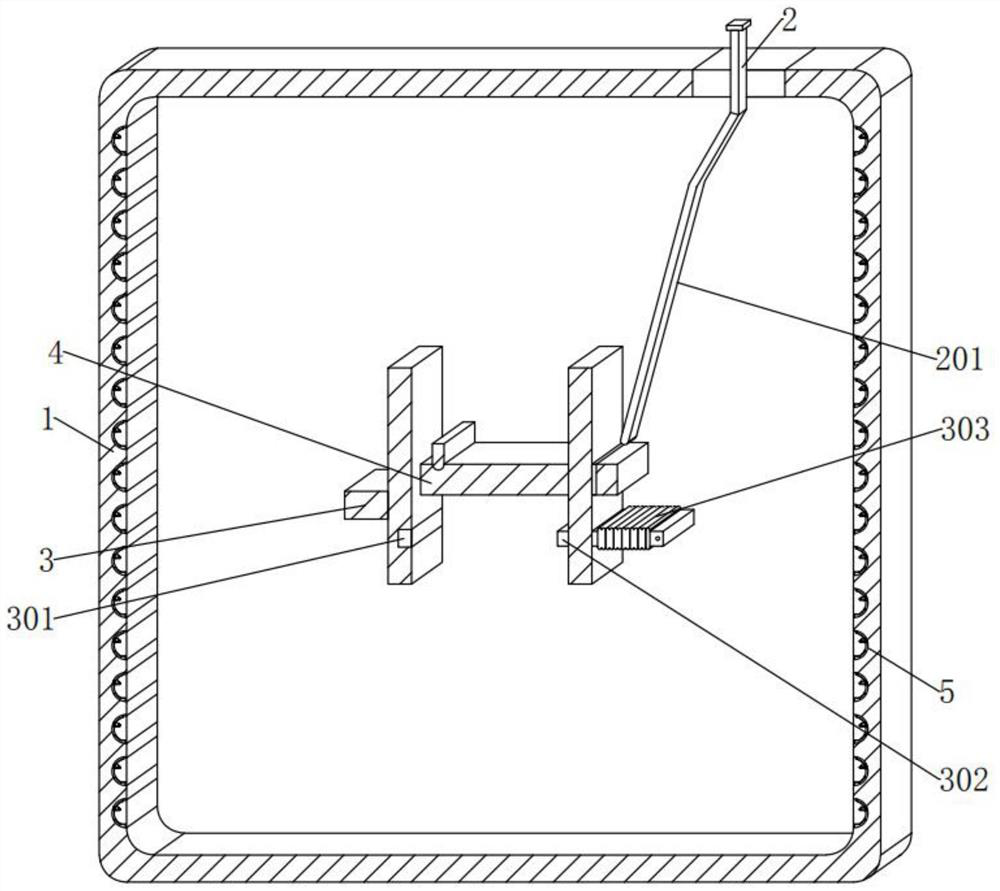

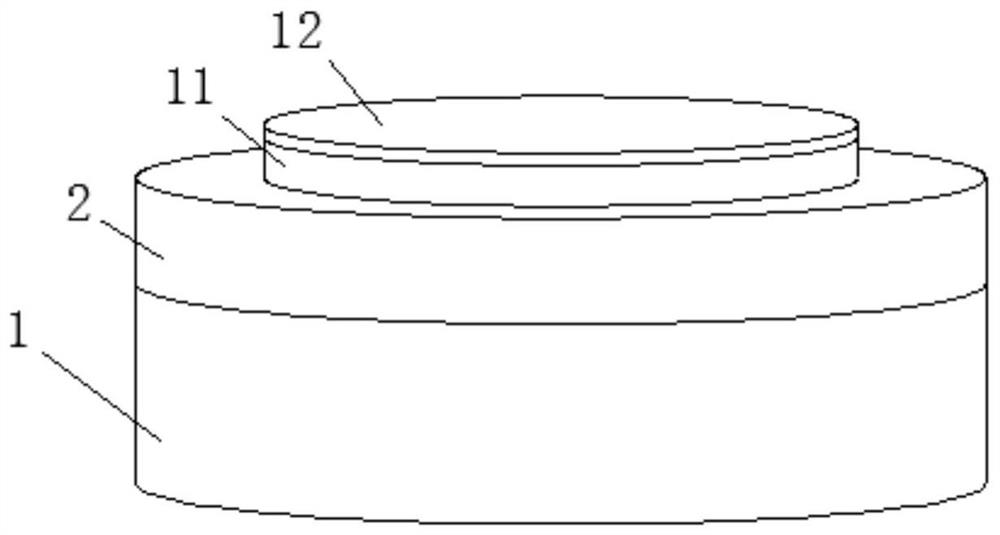

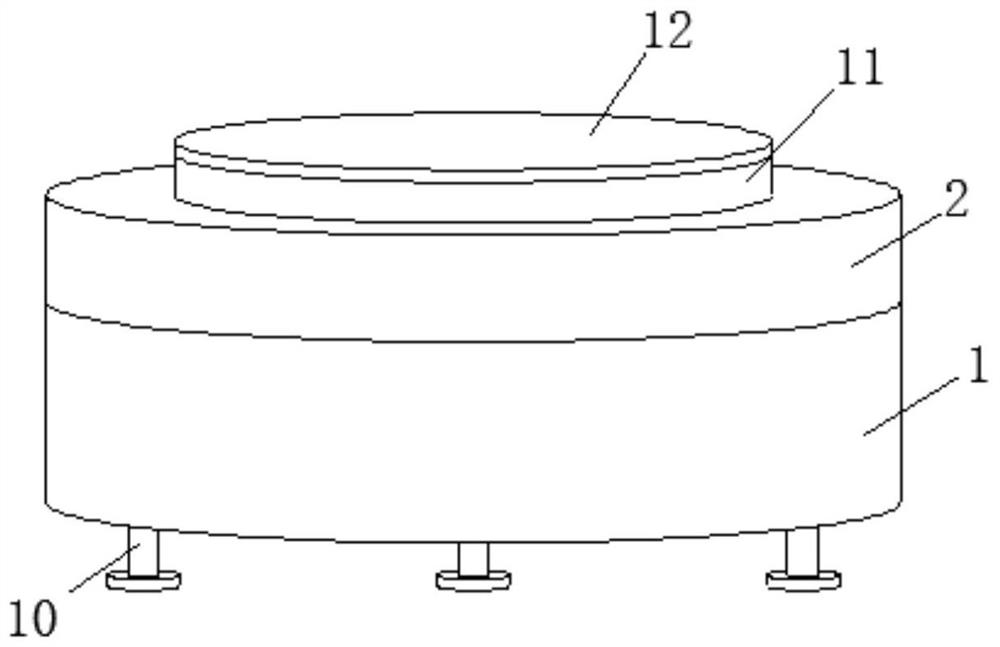

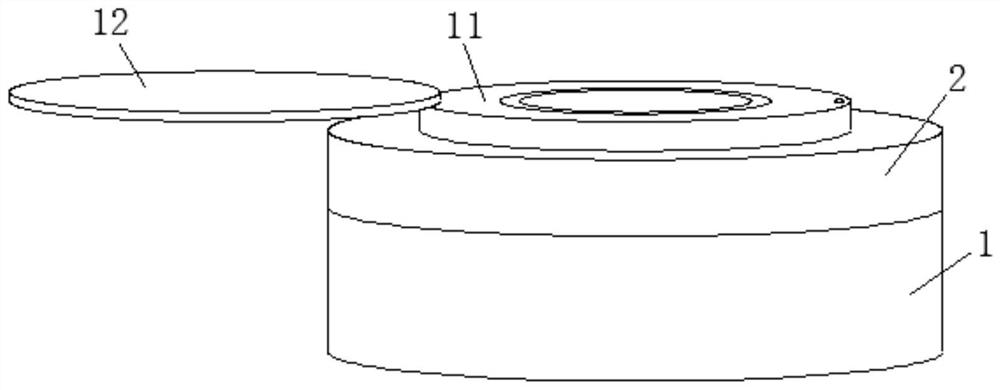

Reaction kettle for processing of particulate matter based on silicone PU plastics rubber court

InactiveCN109395690AReduce resistanceReduce work intensityRotary stirring mixersTransportation and packagingParticulatesDrive motor

The invention discloses a reaction kettle for processing of particulate matter based on a silicone PU plastics rubber court. The reaction kettle includes a reaction kettle body, the outer side of theupper surface of the reaction kettle body is provided with an exhaust pipe and a feeding hopper respectively, and an organic frame is arranged in the middle of the upper surface of the reaction kettlebody. A driving motor is arranged at the top of the frame, and an output shaft of the driving motor runs through the reaction kettle body and is connected with a stirring shaft. The lower end of thestirring shaft is provided with a fixation block, the two sides of the fixation block are provided with telescopic rods, the outer side of each telescopic rod is provided with a reset spring, and thelower ends of the two telescopic rods are provided with second arc scraper blades. The lower end of the stirring shaft is connected with the second arc scraper blades through the telescopic rods, meanwhile the outer sides of the telescopic rods are provided with reset springs, it is ensured that the second arc scraper blades still can make contact with the bottom of the reaction kettle body afterwear, the service life of the second arc scraper blades is long, and the scraping effect is good.

Owner:泰州市鹏程体育设施材料有限公司

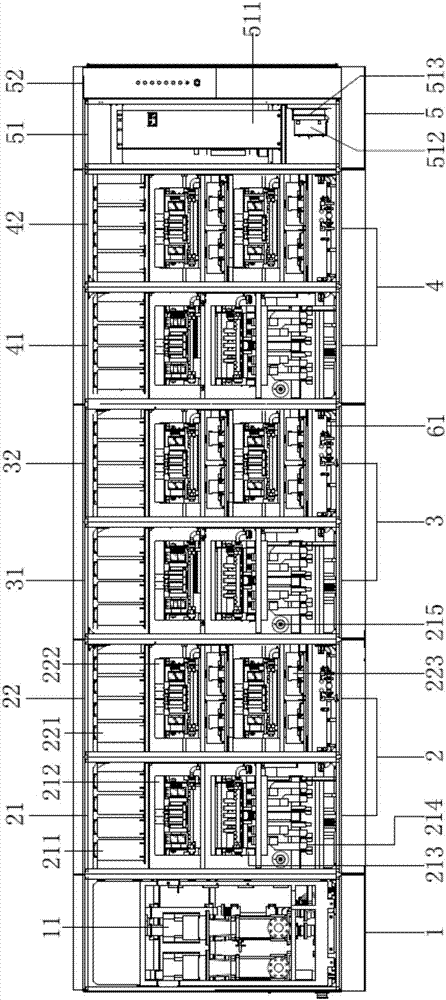

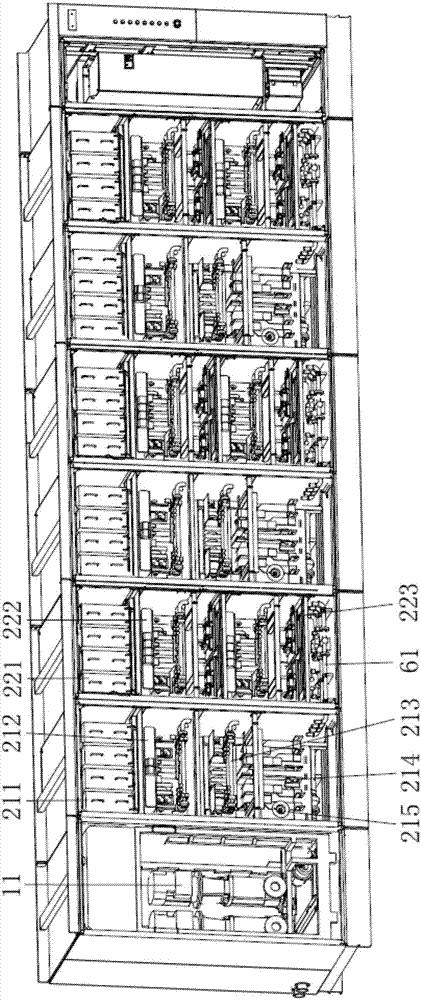

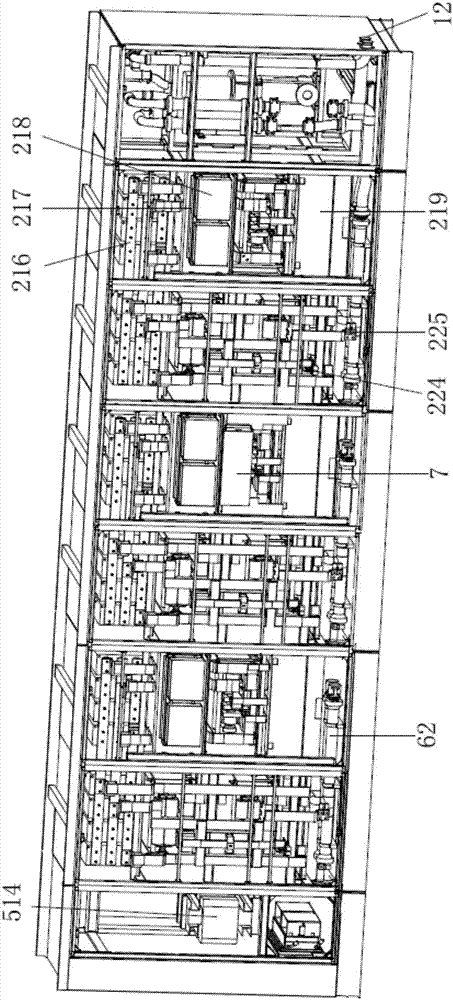

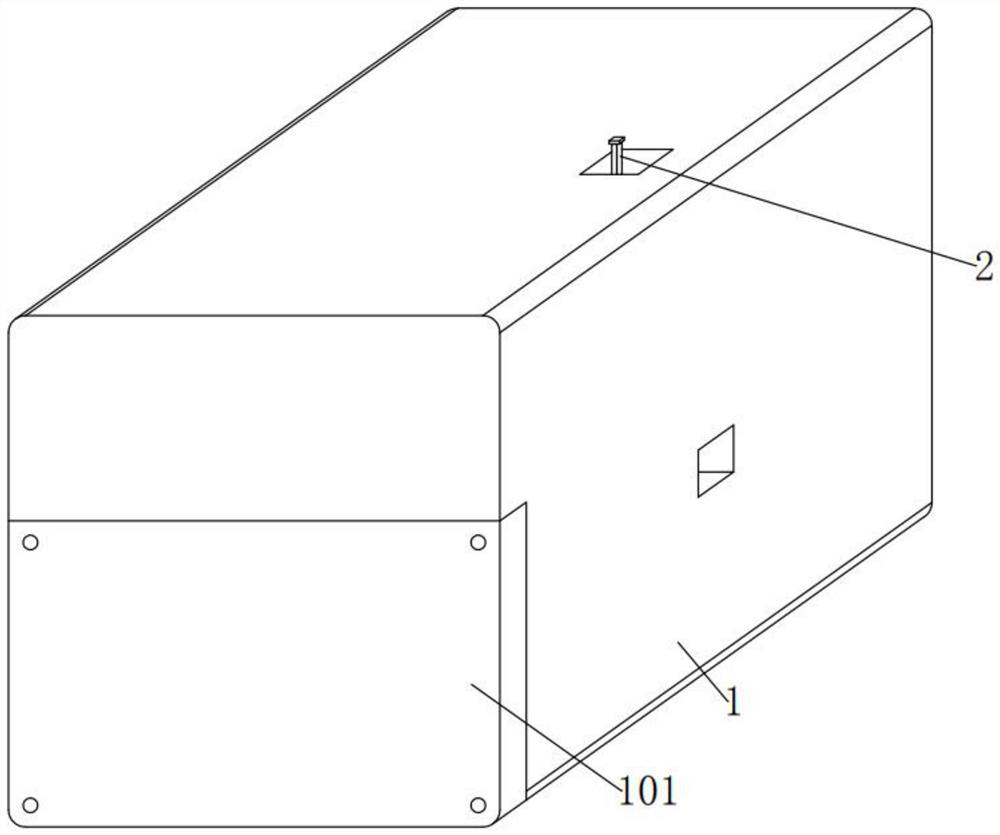

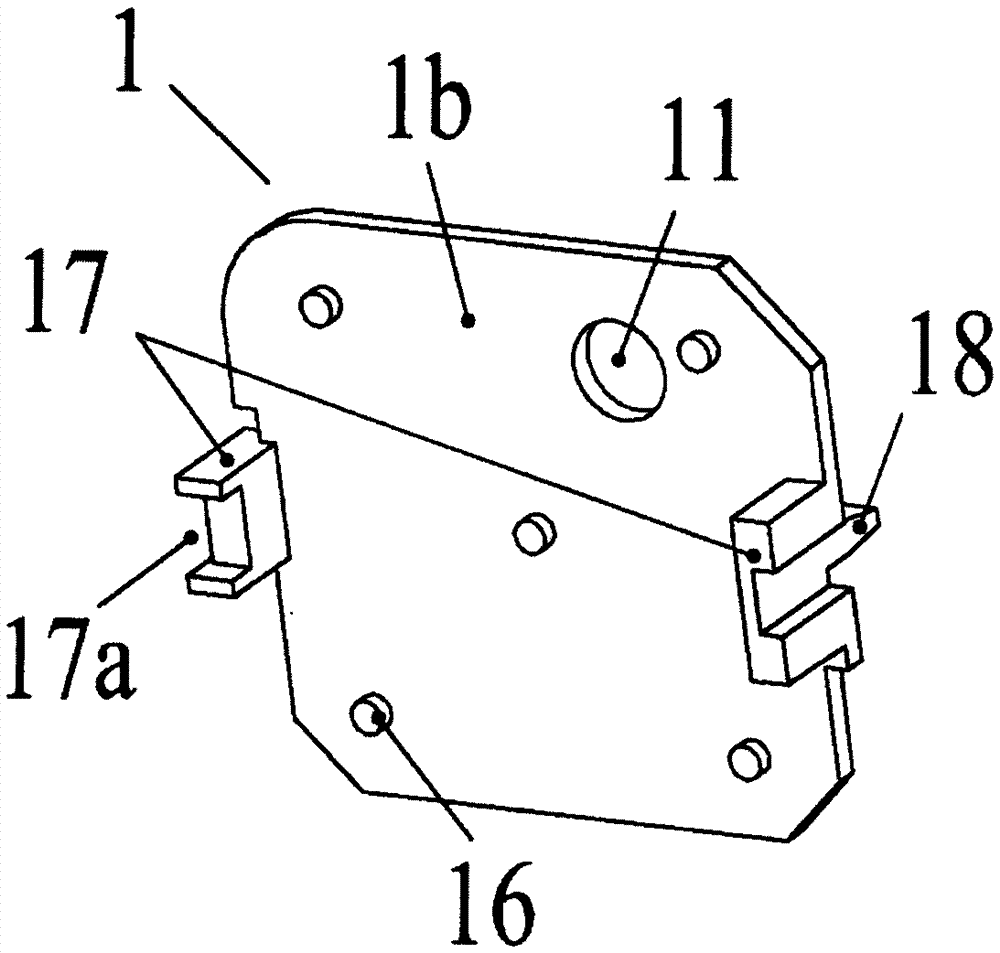

Converter cabinet

PendingCN107026560AEliminate troubleEasy to assembleConversion constructional detailsCooling/ventilation/heating modificationsCapacitanceElectrical conductor

A converter cabinet disclosed by the present invention at least comprises three sub-cabinets, each sub-cabinet comprises a cabinet body, and a first DC bus capacitor module, a rectifier power module, a second DC bus capacitor module and an inverter power module are at least arranged inside the cabinet body. The first and second DC bus capacitor modules are arranged horizontally and parallelly and are electrically connected via a conductor, the rectifier power module is located at the lower part of the first DC bus capacitor module, and a lower incoming line of the rectifier power module is connected with the first DC bus capacitor module via a conductor. The inverter power module is located at the lower part of the second DC bus capacitor module, a lower incoming line of the inverter power module is connected with the second DC bus capacitor module via a conductor, and the structures of the sub-cabinets are same and independent to form one phase.

Owner:SHENZHEN HOPEWIND ELECTRIC CO LTD

Thermal-insulation and degradable mulching film composition and preparation method thereof

InactiveCN107880517AImprove insulation effectHeating fastPlant protective coveringsThermal insulationUltimate tensile strength

Thermal-insulation and degradable mulching film composition is prepared from components in parts by mass as follows: 100 parts of PPC (polypropylene carbonate resin), 50-70 parts of PBAT (polybutyleneadipate terephthalate), 30-50 parts of toughening-modified resin, 2-5 parts of a temperature keeping and increasing additive and 0.1-1.0 part of a nucleating agent. A mulching film melt prepared fromthe mulching film composition is high in strength, excellent in mechanical property, good in temperature keeping and increasing performance and suitable for areas with large day and night temperaturedifference.

Owner:山东天野生物降解新材料科技有限公司

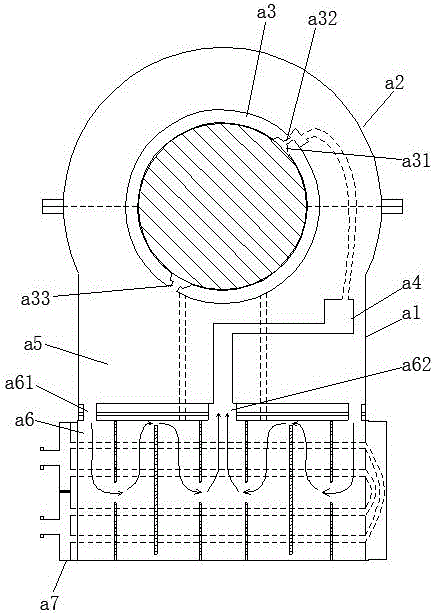

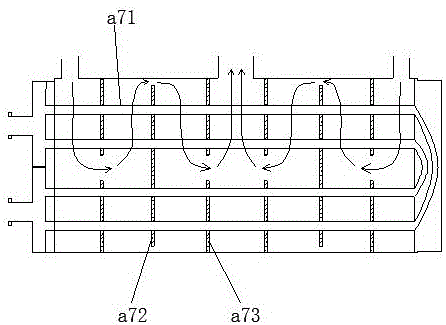

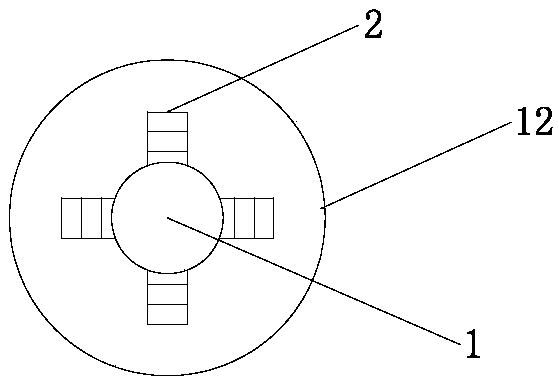

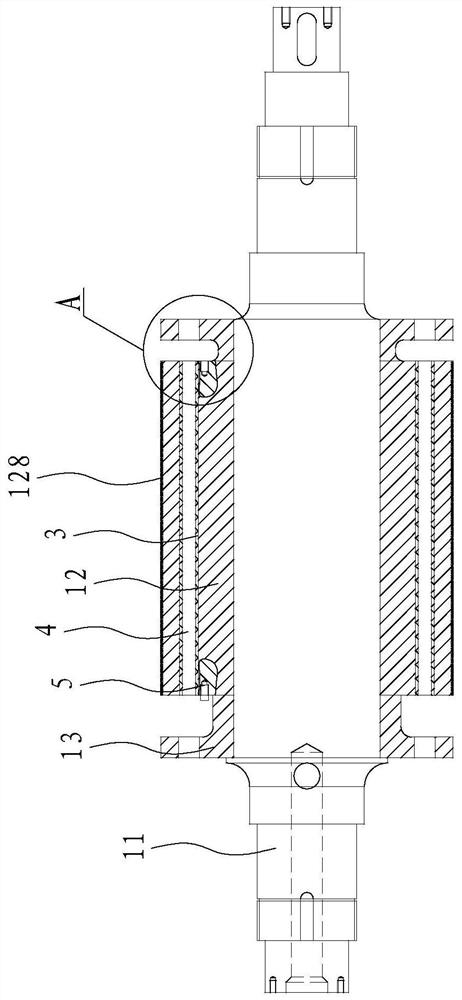

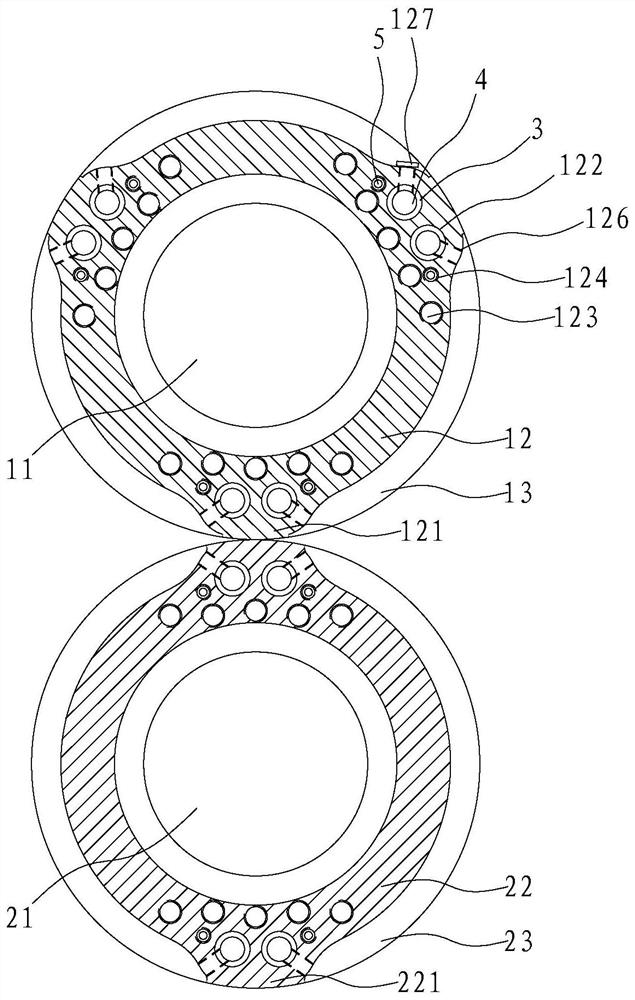

Bearing

PendingCN106678187AAchieve cycleReduce the temperatureHydro energy generationMachines/enginesHigh pressureHigh heat

The invention discloses a bearing. The bearing comprises a bearing pedestal, a bearing cap, a tilting fillet, a supporting bush, a forward thrust pad, a forward thrust disc, a first oil cavity, a second oil cavity, a cooler and an oil-containing cover. The tilting fillet is fixed to the bearing pedestal. The supporting bush is fixed to the inner diameter side of the tilting fillet. The forward thrust pad is fixed to the front side of the tilting fillet. The first oil cavity is a sealing cavity formed by covering the bearing cap and the bearing pedestal. The second oil cavity comprises a hot oil inlet and a cold oil outlet. The second oil cavity communicates with the first oil cavity through the hot oil inlet. The cooler is arranged in the second oil cavity. The oil-containing cover is arranged at the outer diameter side of the forward thrust disc. The oil-containing cover and the forward thrust disc form an oil-containing cavity. An oiling groove is formed in the inner diameter side of the supporting bush. An oil throw-off cavity is formed in the inner diameter side of the forward thrust pad. The oil-containing cavity comprises a high pressure oil outlet and an oil pumping opening. The oil pumping opening communicates with the cold oil outlet of the second oil cavity. The high pressure oil outlet is divided into two oil ducts which communicate with the oiling groove and the oil throw-off cavity correspondingly. The bearing has high heat exchange efficiency, and bearing pad burning can be effectively avoided.

Owner:郭远军

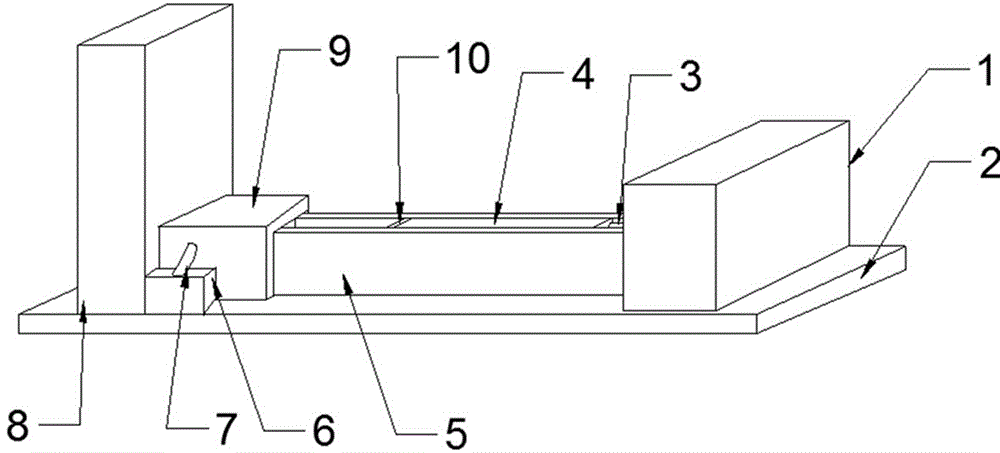

Aluminum material extruding machine

The invention discloses an aluminum material extruding machine in the technical field of equipment manufacturing. The aluminum material extruding machine comprises a platform fixed to the ground. The platform is sequentially provided with a die base, an extruding cylinder, an extruding beam and an air cylinder from left to right. The die base is provided with a die. The extruding beam and a piston rod of the air cylinder are fixed. The die is fixedly connected into the extruding cylinder. The die base, the die, the extruding beam and the extruding cylinder are located on the same axis. The extruding cylinder comprises an inner layer and an outer layer. The outer layer of the extruding cylinder is connected with a vacuum pump through a flexible pipe. One end of the flexible pipe extends into an interlayer formed by the inner layer and the outer layer of the extruding cylinder. The vacuum pump is arranged on the platform. By the adoption of the extruding machine in the scheme, after the vacuum pump is started, air in the interlayer is pumped out to make the interlayer vacuum, the extruding cylinder does not dissipate heat easily, the cooling speed of aluminum materials is low, and the aluminum materials can be formed beneficially.

Owner:ZUNYI HENG JIA ALUMINUM CO LTD

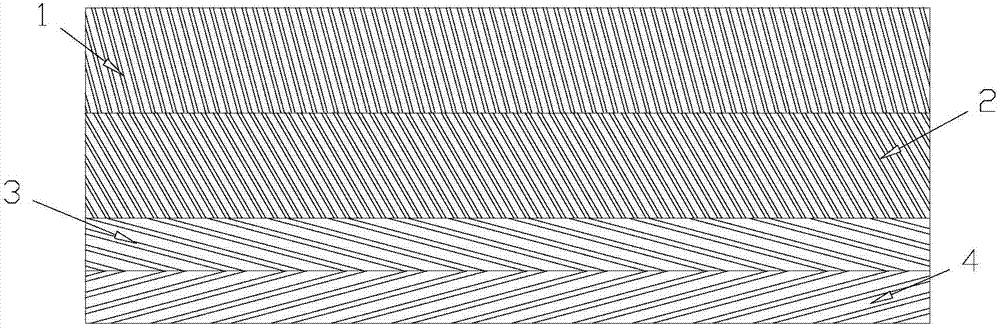

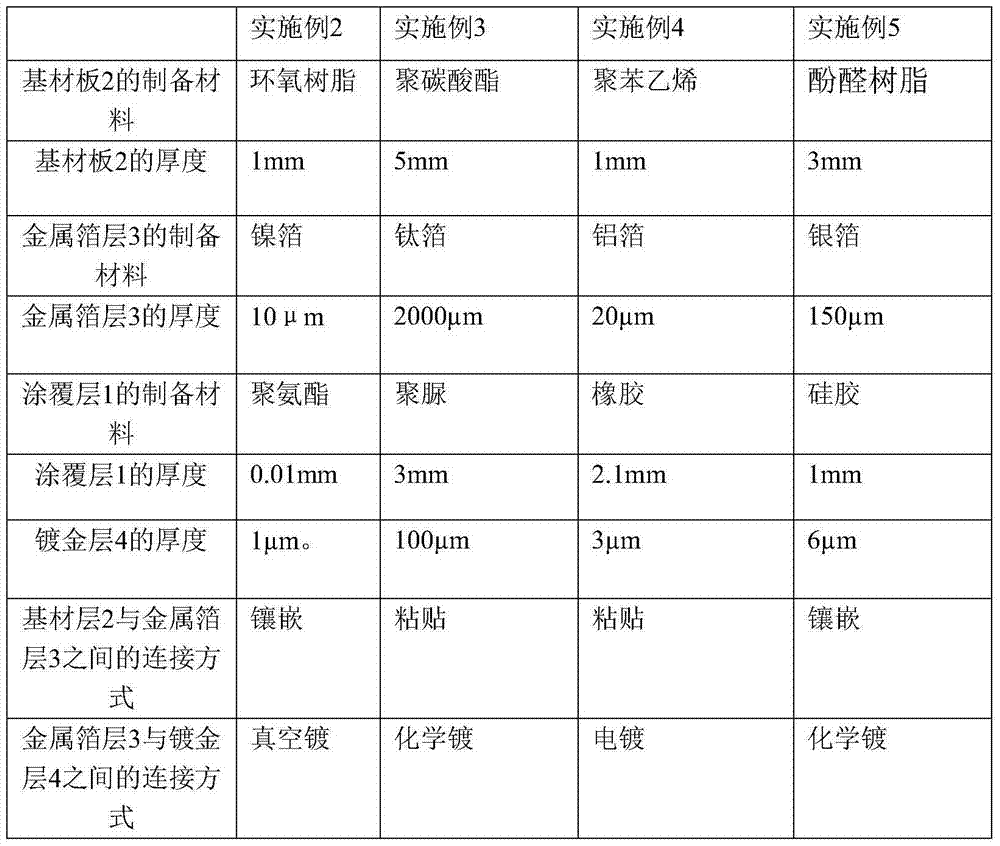

Collector plate of fuel cell as well as preparation method thereof

ActiveCN103811777AIncrease contact areaReduce contact resistanceCollectors/separatorsMetal foilEngineering

The invention discloses a collector plate of a fuel cell. The collector plate of the fuel cell comprises a substrate plate, wherein the substrate plate is a nonmetallic substrate plate; one lateral surface of the substrate plate is coated with a coating layer, and the other lateral surface of the substrate plate is provided with a metal foil layer; the surface of the metal foil layer is coated with a gold coated layer. The collector plate of the fuel cell, which is provided by the invention, has the functions of electric conduction, insulation, sealing, shock absorption, back pressure, heat radiation and the like, and has a wide market prospect.

Owner:江苏氢电新能源有限公司

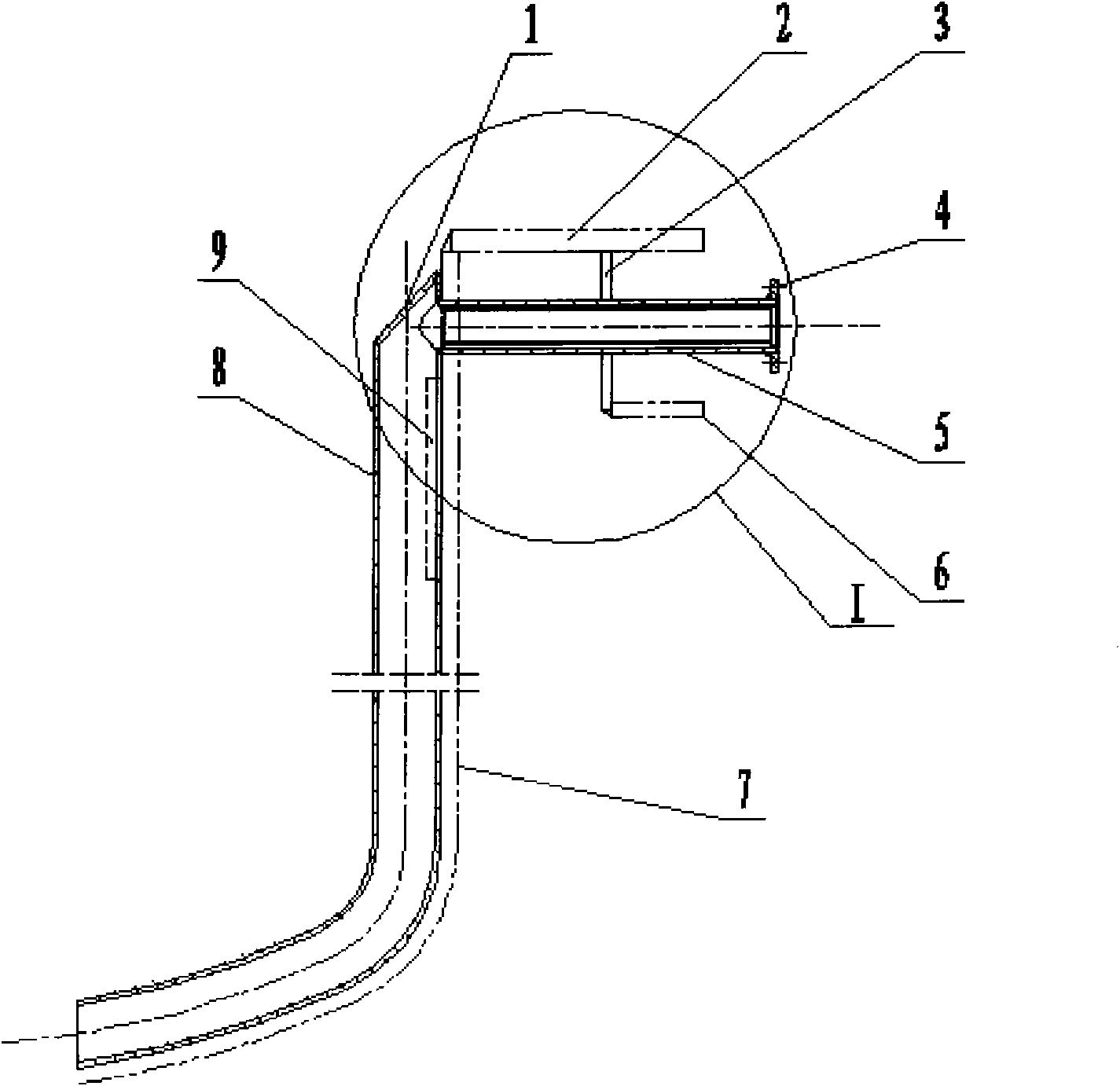

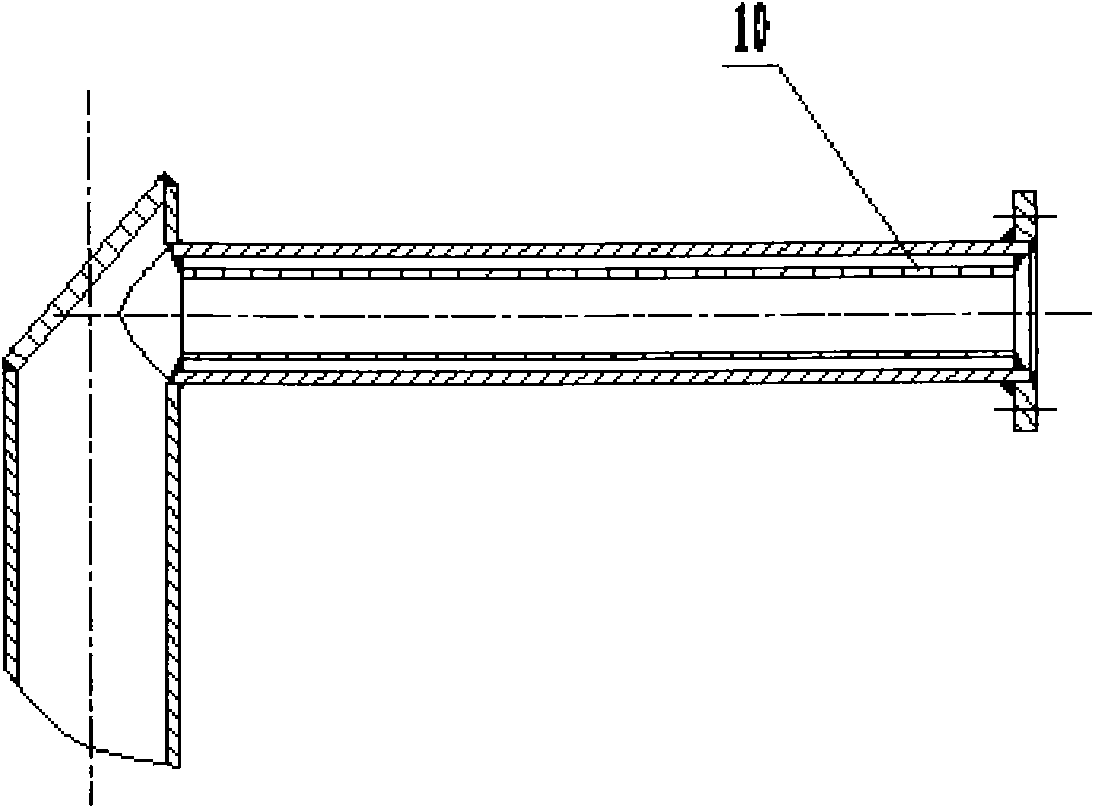

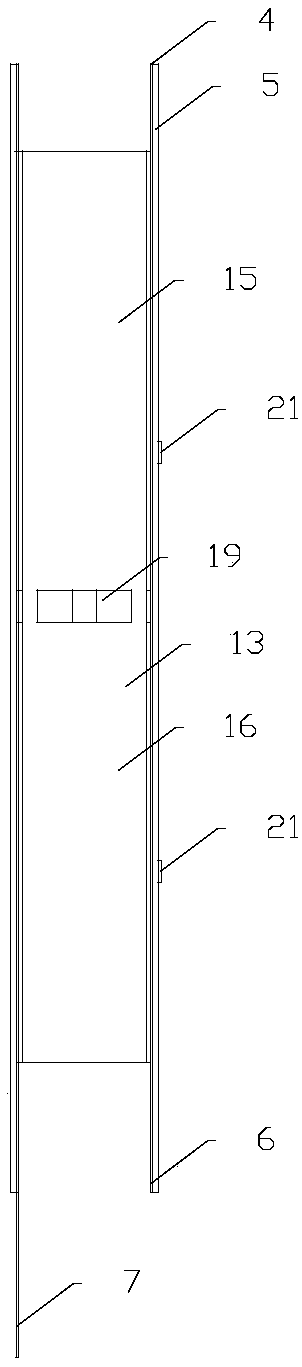

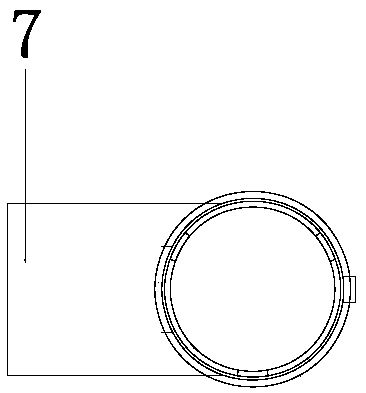

Manufacturing method of magnesium chloride discharge pipe of reactor for producing sponge titanium

The invention introduces a manufacturing method of a magnesium chloride discharge pipe for producing sponge titanium, the magnesium chloride discharge pipe consists of a blocking plate (1), a horizontal pipe flange (4), a horizontal pipe (5), a vertical pipe (8) and a sleeve (10) in the horizontal pipe, wherein a rib plate (9) is used for connecting the vertical pipe (8) with a cylinder body (7) of a reactor together; the horizontal pipe (5) is continuously welded with the cylinder body (7) of the reactor, the vertical pipe (8) and upper and lower flange short cylinder bodies (3); the blocking plate (1) is welded with the vertical pipe (8); the horizontal pipe (5), the sleeve (10) in the horizontal pipe and the horizontal pipe flange (4) constitute a magnesium chloride discharge output pipe; and a certain gap is retained between the horizontal pipe (5) and the sleeve (10) in the horizontal pipe. The manufacturing method can avoid weld cracking of the horizontal pipe of the magnesium chloride discharge pipe, lead the sleeve at the inner layer to expand and contract freely and prolong the service life; when the horizontal pipe of the magnesium chloride discharge pipe is blocked, the horizontal pipe can be cut open for taking out the inner sleeve; and the manufacturing method can reduce the blocking probability of the magnesium chloride discharge pipe.

Owner:洛阳双瑞万基钛业有限公司

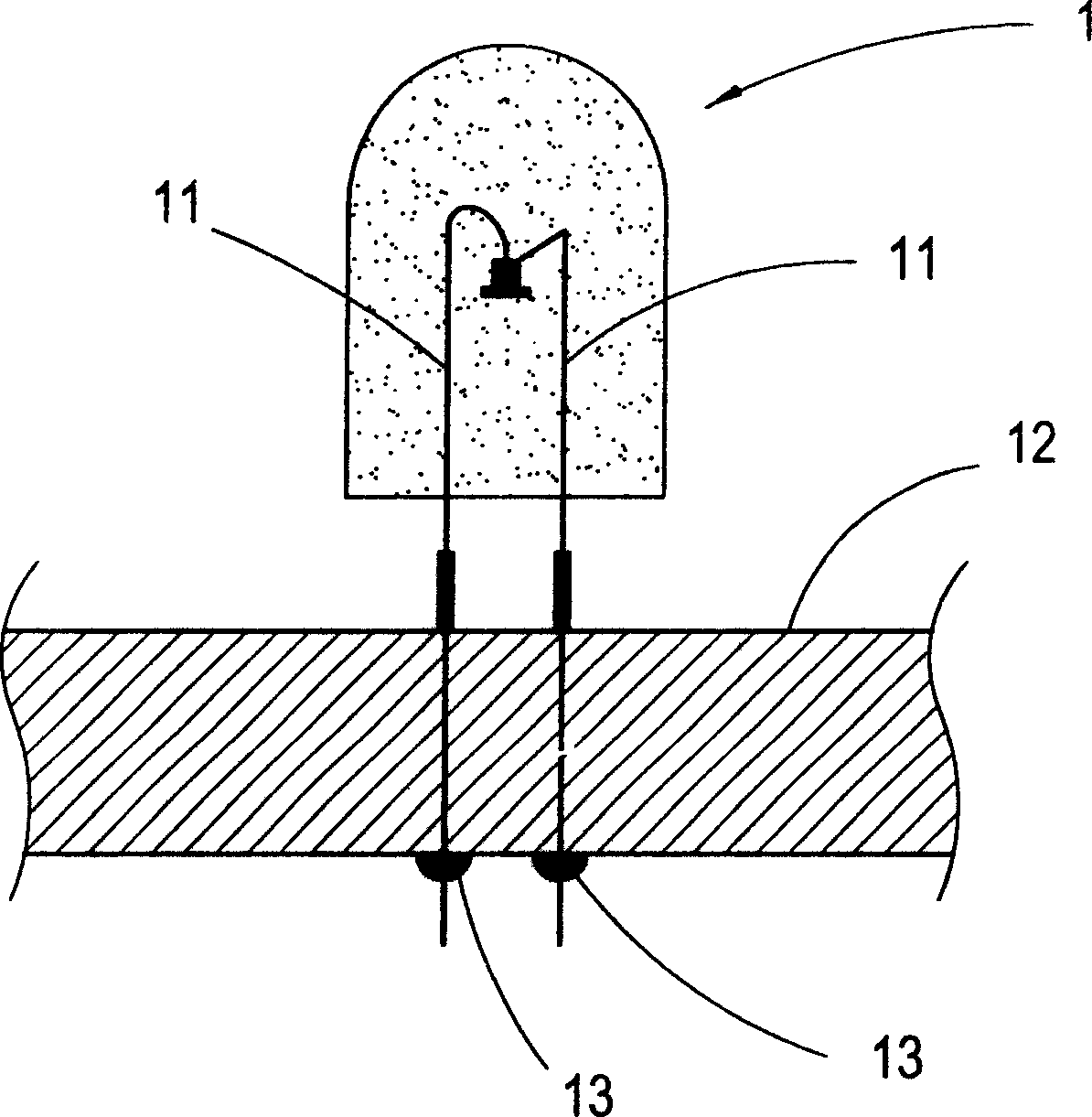

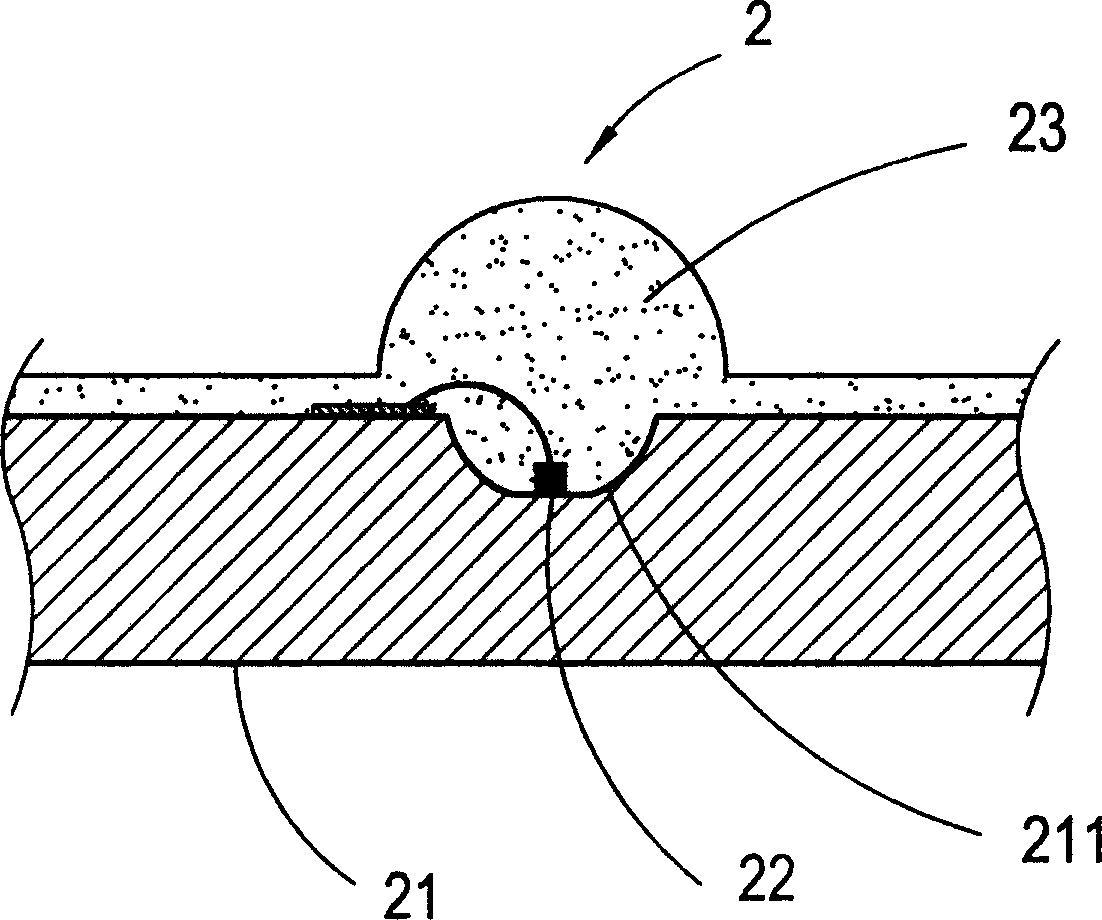

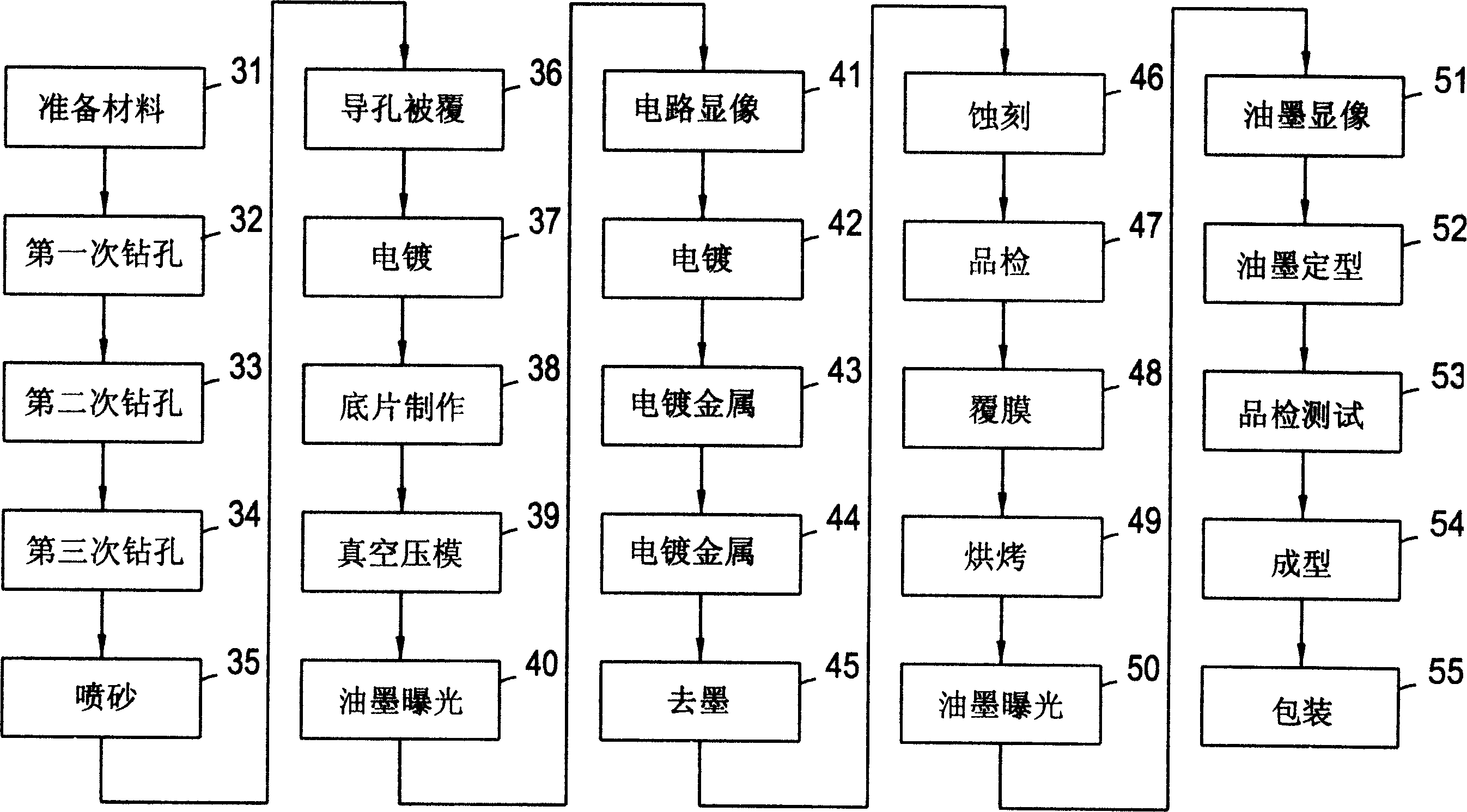

Circular arc flat-bottom cupped light emitting diode manufacturing method

InactiveCN1173416CGood flatnessGood heat dissipationSolid-state devicesSemiconductor devicesIonPrinted circuit board

A method for manufacturing a light emitting diode in the shape of cup with a curved surface and planar bottom comprises two stages: in first stage, to produce a printed circuit board in the shape of cup, a printed circuit board is placed in a drill and is drilled to a cup shape with a curved surface and planar bottom using a particular mill at 12000-25000 rpm, after the drilling of other circuit hole is completed, the interior of the cup is fully polished using a sandblast device, and then is plated with copper ion, then is plated nickel and gold; in second stage, to produce an LED in the form of cup, the printed circuit board produced thus is applied glue, then a chip is fixed on the printed circuit board, and then baking, bonding, testing, injecting glue and baking are performed successively, thereby forming an LED with the shape of cup. The LED manufactured according to the present invention shows good performances, commerciality and many uses.

Owner:詹宗文

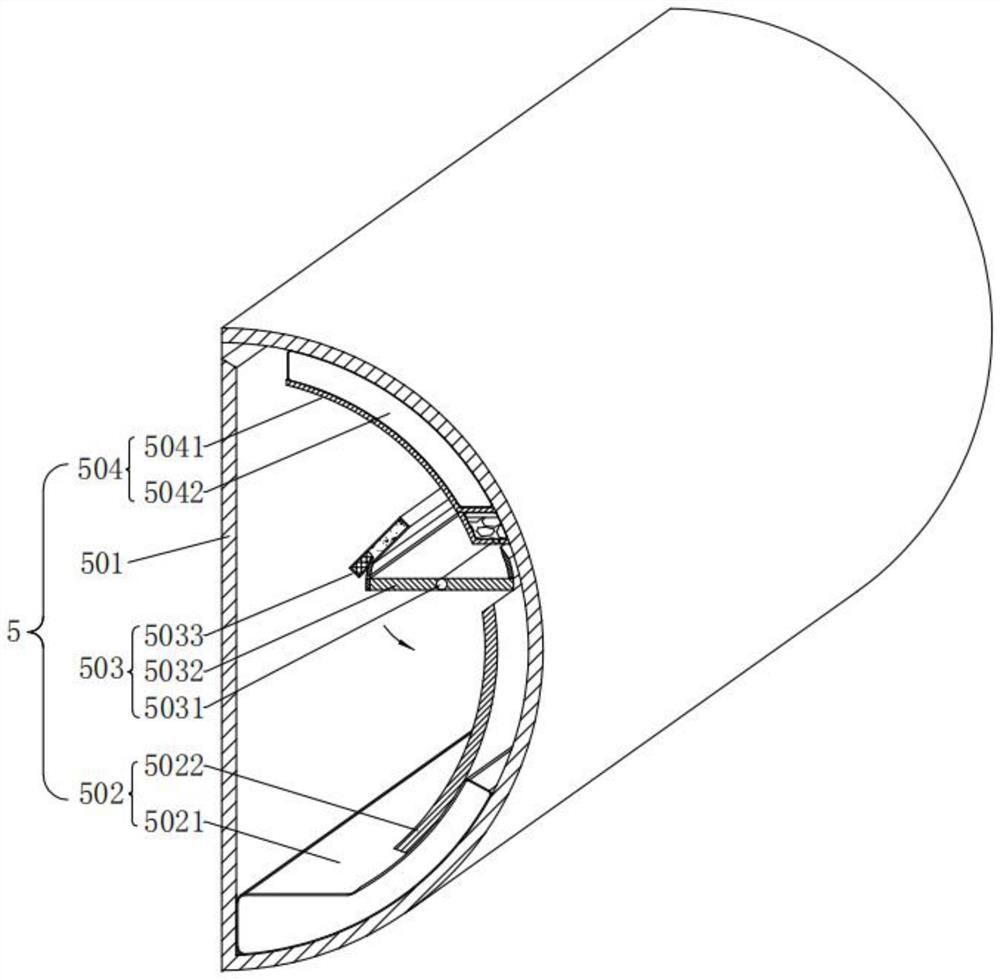

Low-temperature non-combustion fLue-cured tobacco heating device, system and method

PendingCN108851239AAvoid wastingAvoid wasteful situationsTobacco devicesElectrical resistance and conductanceHeat-shrinkable sleeve

The invention discLoses a Low-temperature non-combustion fLue-cured tobacco heating device, a system and a method. The device comprises, from top to bottom, a smoking port, a smoking port connector, aheating pipe, an air inLet connector, an air inLet, a PCBA connected to a heat pipe circuit, a MCU disposed on the PCBA and a thermistor connected to the MCU; wherein the heating pipe comprises a metaL pipe, a heating fiLm and a heat shrinkabLe sLeeve from the inside to the outside. The heating fiLm is provided with a heating eLement, and the heat shrinkabLe sLeeve is used for fixing the heatingfiLm. The heating fiLm is divided into two or more parts, and the two or more parts of heating fiLms are connected with the MCU respectiveLy. The muLti-stage heating of the device can make the smoke bomb more uniform, and has the advantages of fast smoke-exiting speed and tobacco saving.

Owner:深圳市安迪能电子科技有限公司

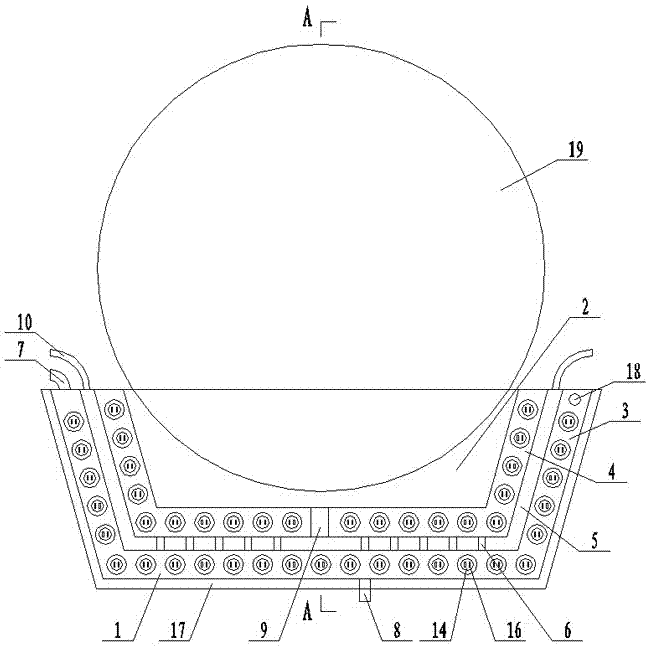

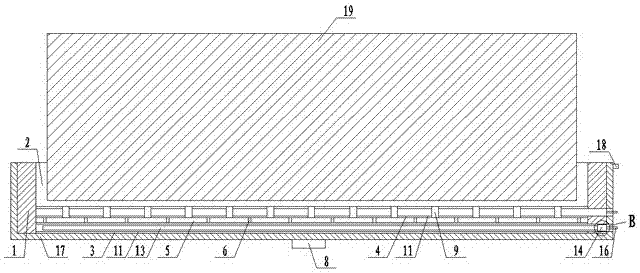

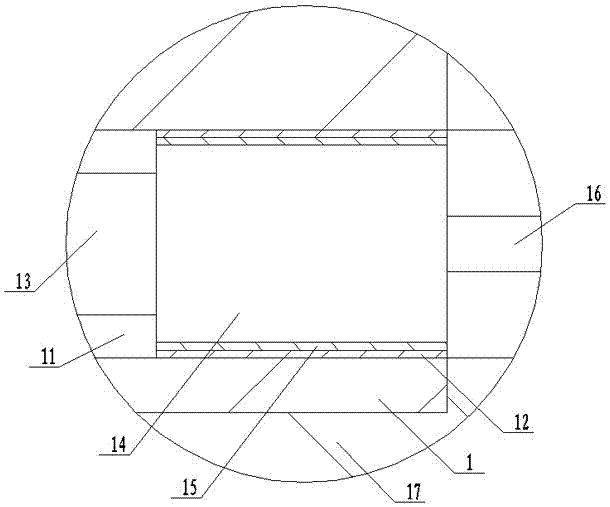

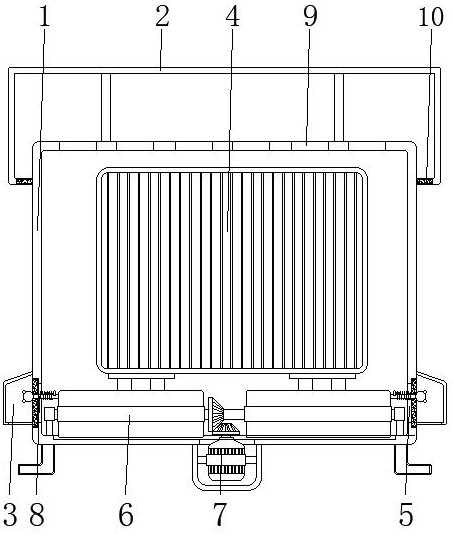

Compound machine glue tank heat preservation device

InactiveCN107008626AImprove cooling effectImprove insulation effectLiquid surface applicatorsCoatingsPetroleum engineering

The invention discloses a compound machine glue tank heat preservation device. The device comprises a base and a U-shaped glue tank arranged in the base. The base is internally provided with an outer U-shaped heat conduction oil cavity and an inner U-shaped heat conduction oil cavity. A U-shaped glue preheating cavity is arranged in the base and located between the outer U-shaped heat conduction oil cavity and the inner U-shaped heat conduction oil cavity. The middle of the lower end of the outer U-shaped heat conduction oil cavity and the middle of the lower end of the inner U-shaped heat conduction oil cavity communicate through a plurality of heat conduction oil connecting pipes arranged intelligent the U-shaped glue preheating cavity. A heat conduction oil inlet communicating with the outer U-shaped heat conduction oil cavity is arranged on the base and located on one side of the upper end of the outer U-shaped heat conduction oil cavity. An oil outlet communicating with the outer U-shaped heat conduction oil cavity is arranged on the base and located at the lower end of the outer U-shaped heat conduction oil cavity. The middle of the lower end of the U-shaped glue preheating cavity communicates with the U-shaped glue tank through a plurality of glue connecting pipes arranged in the inner U-shaped heat conduction oil cavity.

Owner:JIANGSU HONGHUA SPECIAL EQUIP CO LTD

Pear insect-pest prevention method

The present invention relates to a method for preventing insect pest of pear, mainly comprising covering bag. The present invention is characterized by covering the young fruits with the bags in the manner of packaging when the pear is young fruit. The method can control the insect pest effectively, and provide a foundation for producing the pear containing no toxic or harmful elements for human health.

Owner:胡美兰

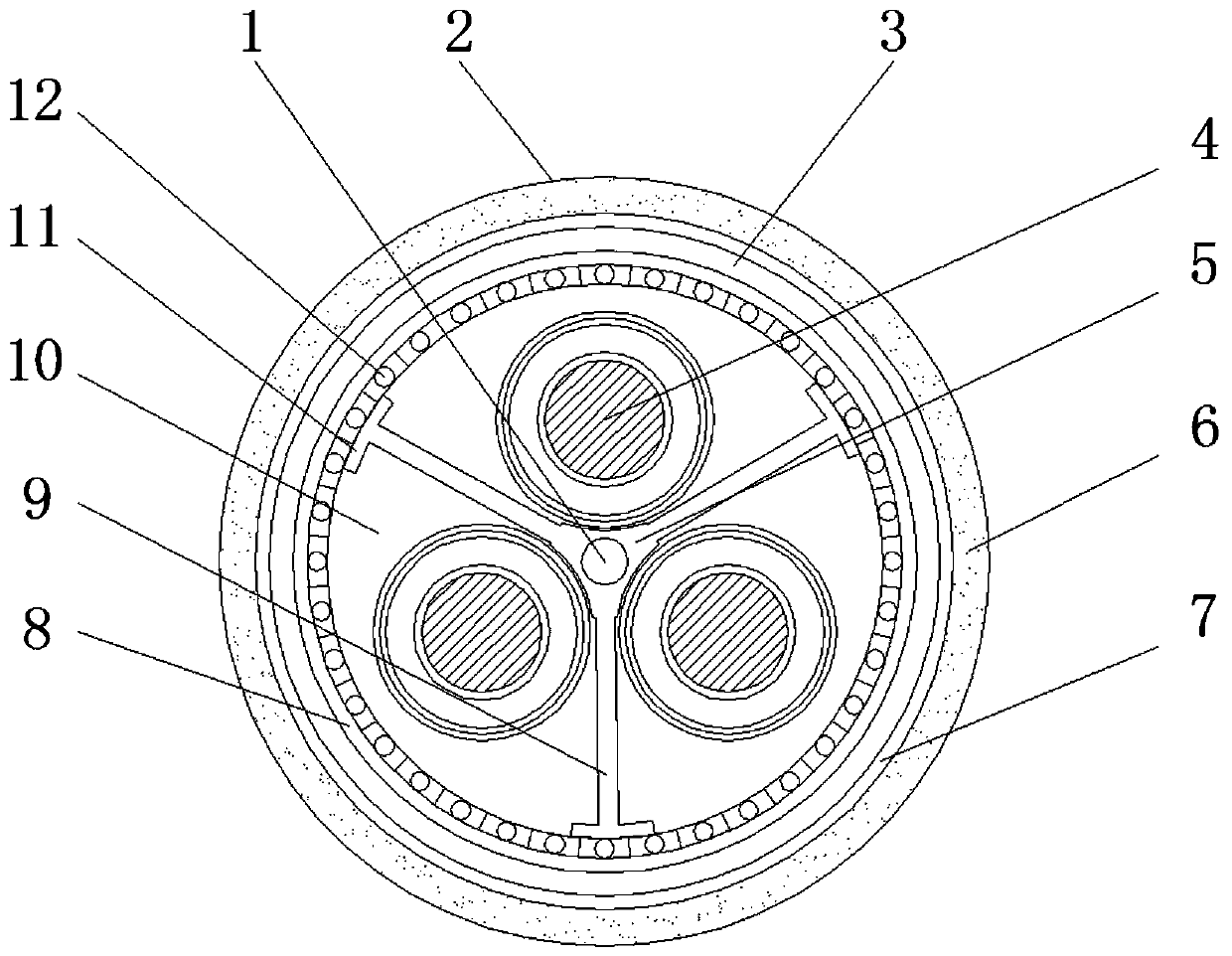

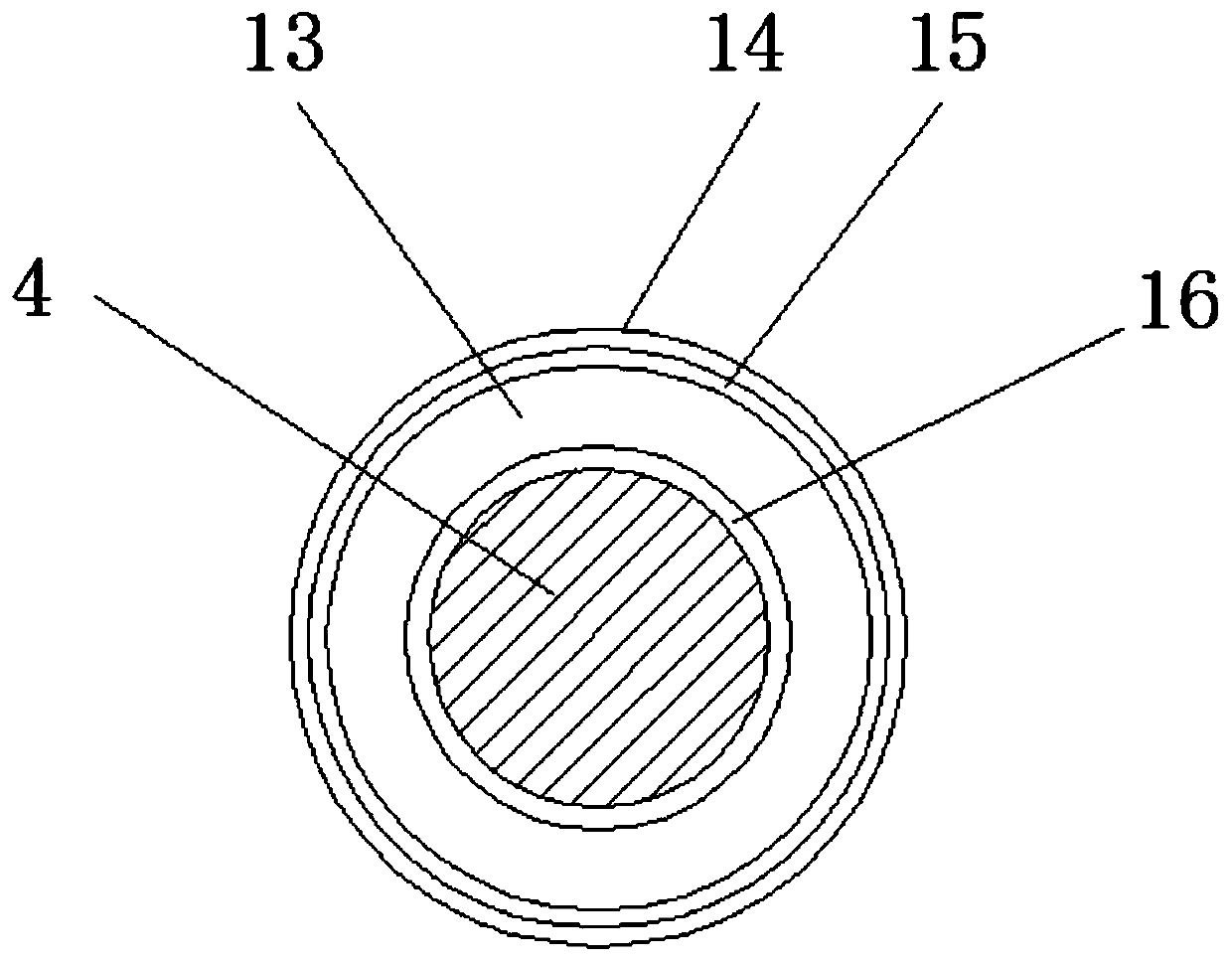

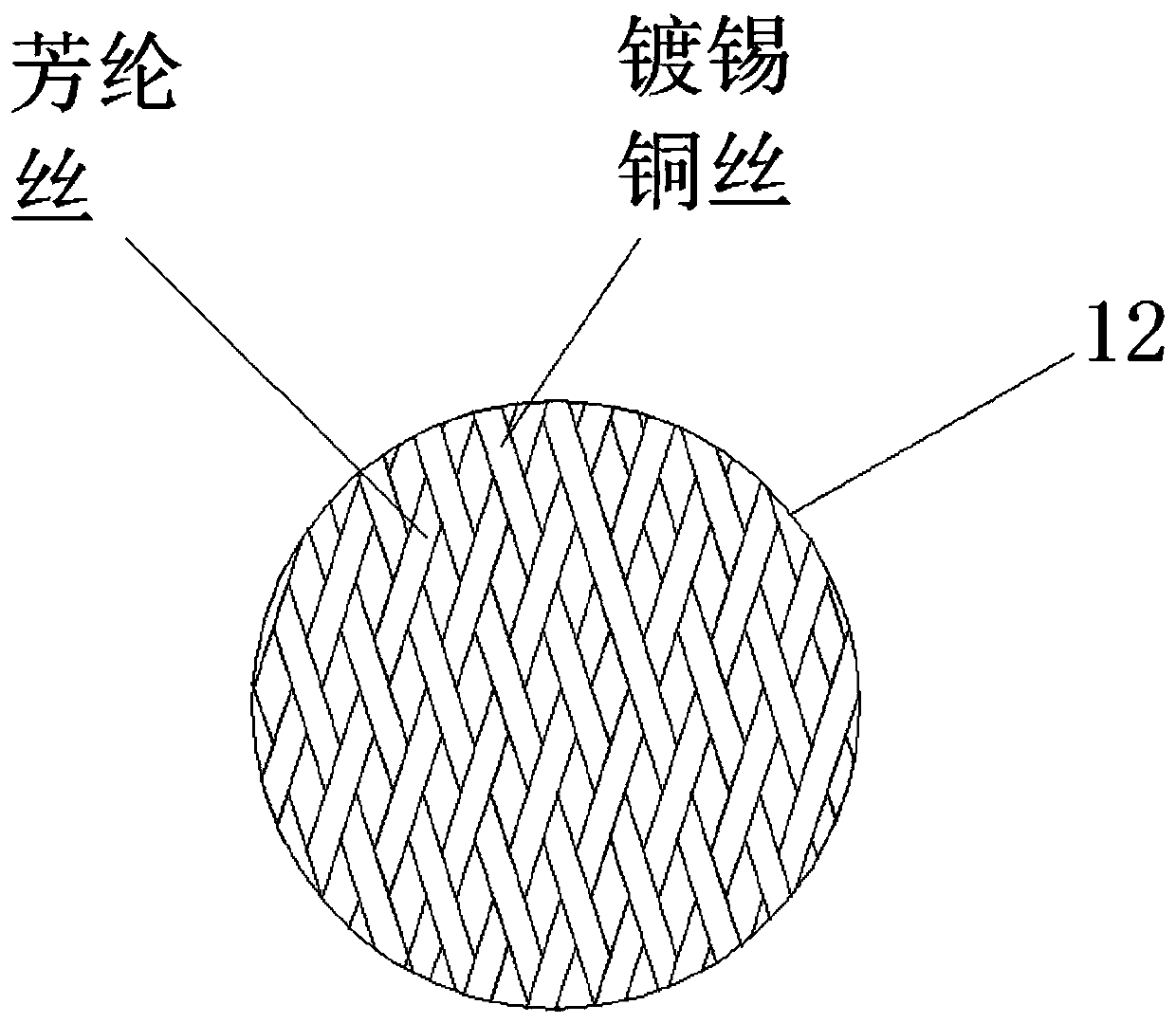

Ultraviolet-proof and corrosion-resistant medium-pressure rubber flexible cable for ships

InactiveCN110060813AImprove water resistanceImprove heat resistanceRubber insulatorsNon-insulated conductorsCorrosion resistantEngineering

The invention discloses an ultraviolet-proof and corrosion-resistant medium-pressure rubber flexible cable for ships; the cable comprises a cable body, cable cores, a connecting seat and an outer sheath layer, wherein metal connecting blocks are uniformly arranged at the middle position of the inner part of the cable body at equal intervals. The metal connecting blocks are uniformly arranged in the cable bodies on the inner sides of the three cable cores at equal intervals, the metal connecting blocks are connected through a connecting ball, and a supporting rod is arranged on the metal connecting blocks; the interior of the cable cores can also generate heat during use, and the cable cores are not easy to dissipate heat; one sides, close to each other, of the cable cores are connected byusing the connecting blocks, so that the heat conduction of the metal connecting blocks is utilized, the heat is conveniently transferred, and the inside of the cable is uniformly heated, the flexibility of the cable cannot be influenced by the hinged connecting blocks; in addition, the bearing capacity of the cable is improved by the supporting rod, and damage caused by extrusion deformation of the cable is avoided; and moreover, the two adjacent cable cores also can be blocked, so that leakage between the cable cores caused by mutual abrasion is avoided, and the service life of the cable isprolonged.

Owner:ANHUI LINGYU CABLE TECH

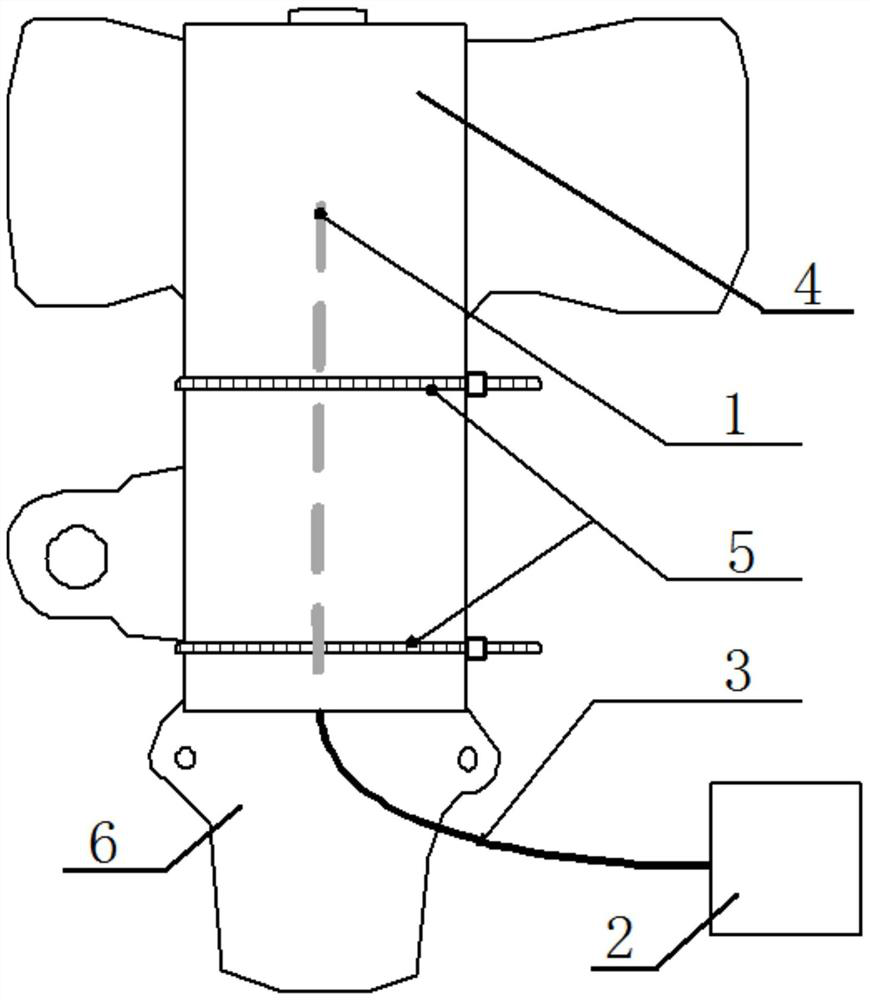

Device for monitoring cable head fault online and monitoring method thereof

PendingCN113125035AGive full play to high voltageImmune to electromagnetic interferenceElectric connection testingThermometers using physical/chemical changesAdhesive beltStrapping

The invention relates to the technical field of cable monitoring, in particular to a device for monitoring a cable head fault online and monitoring method thereof. The device comprises an optical fiber temperature measurement probe, an instrument, an optical fiber patch cord, a sheath and a high-temperature strapping tape, wherein he optical fiber temperature measurement probe is fixed on the surface of a cable head corresponding to a hot spot through using a high-temperature adhesive tape, the optical fiber temperature measurement probe is connected with an instrument through the optical fiber patch cord, and the sheath wraps the outer sides of the optical fiber temperature measurement probe and the cable and is fastened and fixed by the high-temperature strapping tape.

Owner:FUJIAN CHUANZHENG COMM COLLEGE

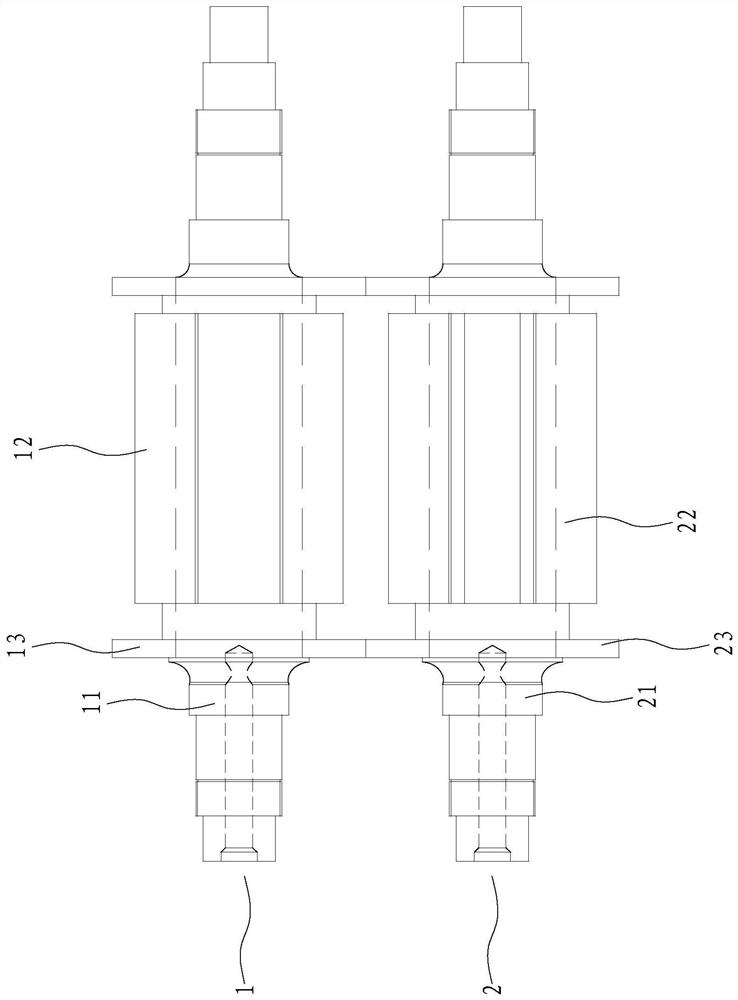

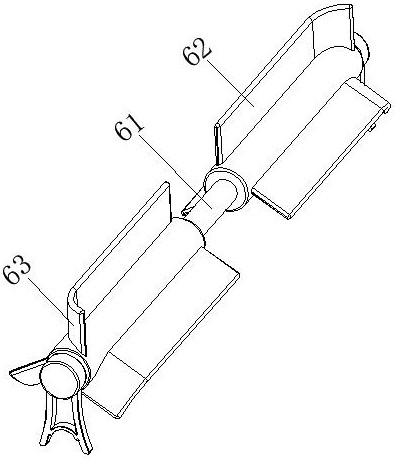

Pull-ups hot welding knife roll mechanism

The invention relates to the field of disposable hygienic product equipment, and particularly relates to a pull-ups hot welding knife roll mechanism. The pull-ups hot welding knife roll mechanism comprises a machine frame, a hot knife roll rotationally arranged on the machine frame and a hot smooth roll rotationally arranged on the machine frame; the hot knife roll comprises a knife roll shaft, aknife roll body arranged on the knife roll shaft in a sleeving mode and knife roll protection rings arranged on the two sides of the knife roll body, three knife roll convex parts are arranged on theknife roll body in an outward protruding mode, the hot smooth roll comprises a smooth roll shaft, a smooth roll body arranged on the smooth roll shaft in a sleeving mode and smooth roll protection rings arranged on the two sides of the smooth roll body, two smooth roll convex parts are arranged on the smooth roll body in an outward protruding mode, and the width of the smooth roll convex parts islarger than that of the knife roll convex parts, the outer diameter of the knife roll convex parts is smaller than that of the knife roll protection rings, the difference value ranges from 0.05 mm to0.2 mm, the outer diameter of the smooth roll convex parts is smaller than that of the smooth roll protection rings, and the difference value ranges from 0.05 mm to 0.2 mm. According to the pull-ups hot welding knife roll mechanism, and the technical problem that in the prior art, the pull-ups hot welding mechanism is not firm in hot-press sewing or perforations are generated in the hot-press sewing is solved.

Owner:QUANZHOU HANWEI MACHINERY MFG

Overload protection device for electricity meter

InactiveCN113702678AAvoid accumulationEasy to prevent dustTime integral measurementEngineeringStructural engineering

The invention provides an overload protection device for electricity meter, the overload protection device comprises a shell, a sealing cover, a straight shaft, a shifting rod, a permanent magnet, a first electrode plate, a second electrode plate, a conductive coil, a sliding groove and dustproof assemblies, and a plurality of dustproof assemblies capable of preventing dust accumulation are embedded in the inner wall of the longitudinal side of the shell in the up-down vertical direction in an equally adjacent mode, each dustproof assembly comprises a dust collection shell, a deformation assembly capable of deforming after dust enters to promote dust prevention, a movable assembly capable of moving after dust enters to promote dust prevention and an anti-overflow assembly capable of preventing the collected dust from overflowing. According to the overload protection device for the electricity meter, the dustproof performance of the shell can be enhanced, even if external dust is brought into the shell through the movable opening in the moving process of the straight shaft, the dust can be collected and cleaned in time, the situation that the dust is accumulated in the shell and is not prone to heat dissipation is prevented, and the normal protection effect of the device on the electricity meter is guaranteed.

Owner:珠海市华能智造实业有限公司

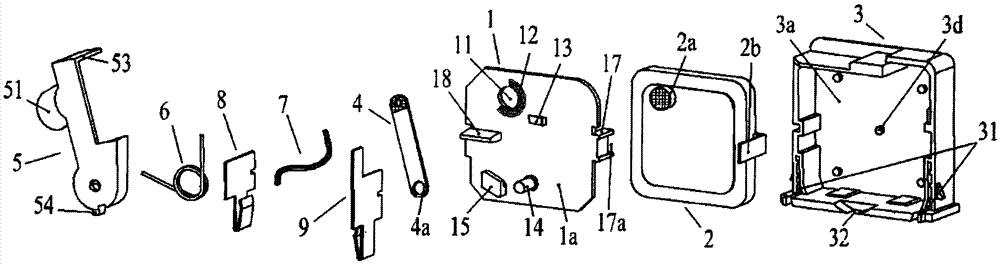

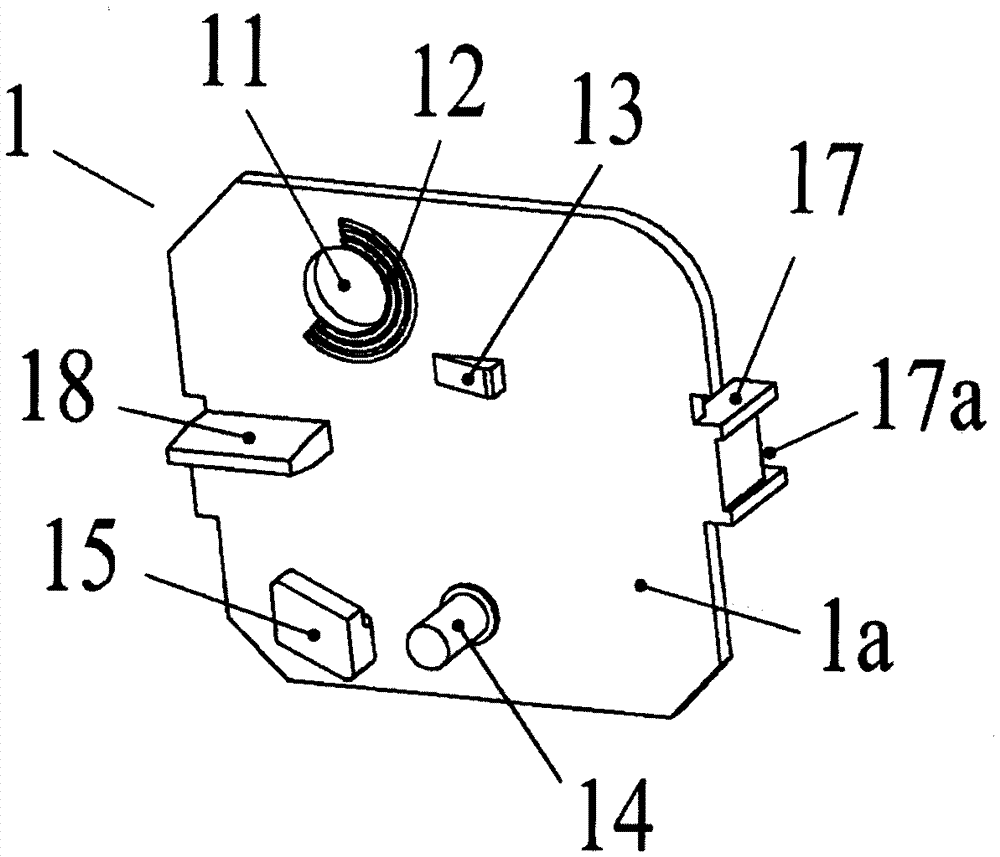

Shielding and insulating surge protection device

InactiveCN107039960AAvoid the hidden danger of secondary conductionThe hidden danger of secondary conductionEmergency protective arrangements for limiting excess voltage/currentEngineeringSurge protector

The invention discloses a shielding insulation type surge protection device for surge protection, which includes an arc shielding mechanism composed of a retainer, a tripping swing arm and an elastic member, a thermal response switch assembly, a voltage sensitive assembly and a support Functional base. When the surge protection device operates quickly due to factors such as surges on the line, it can reliably block the short-circuit arc caused by the action of the thermal response switch and ensure that the protection device is completely separated from the line.

Owner:GUANGXI NANNING BAILANSI SCI & TECH DEV

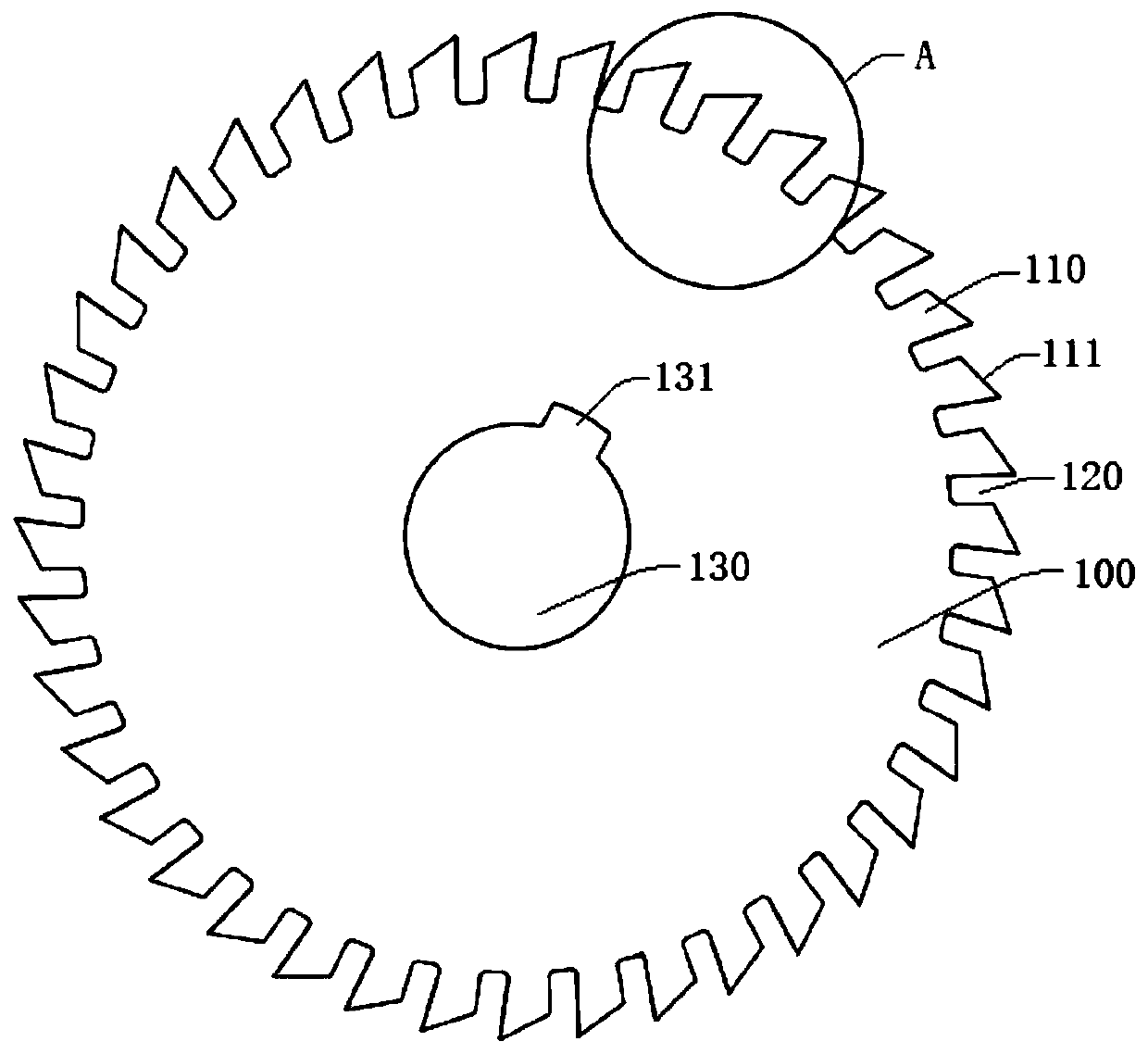

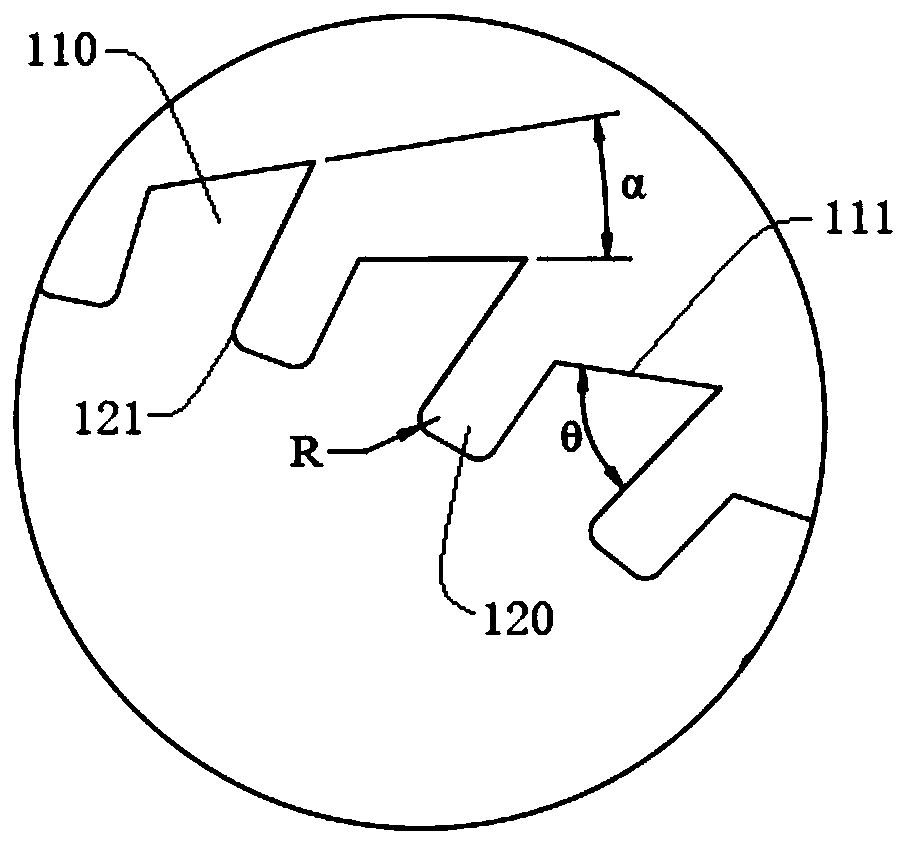

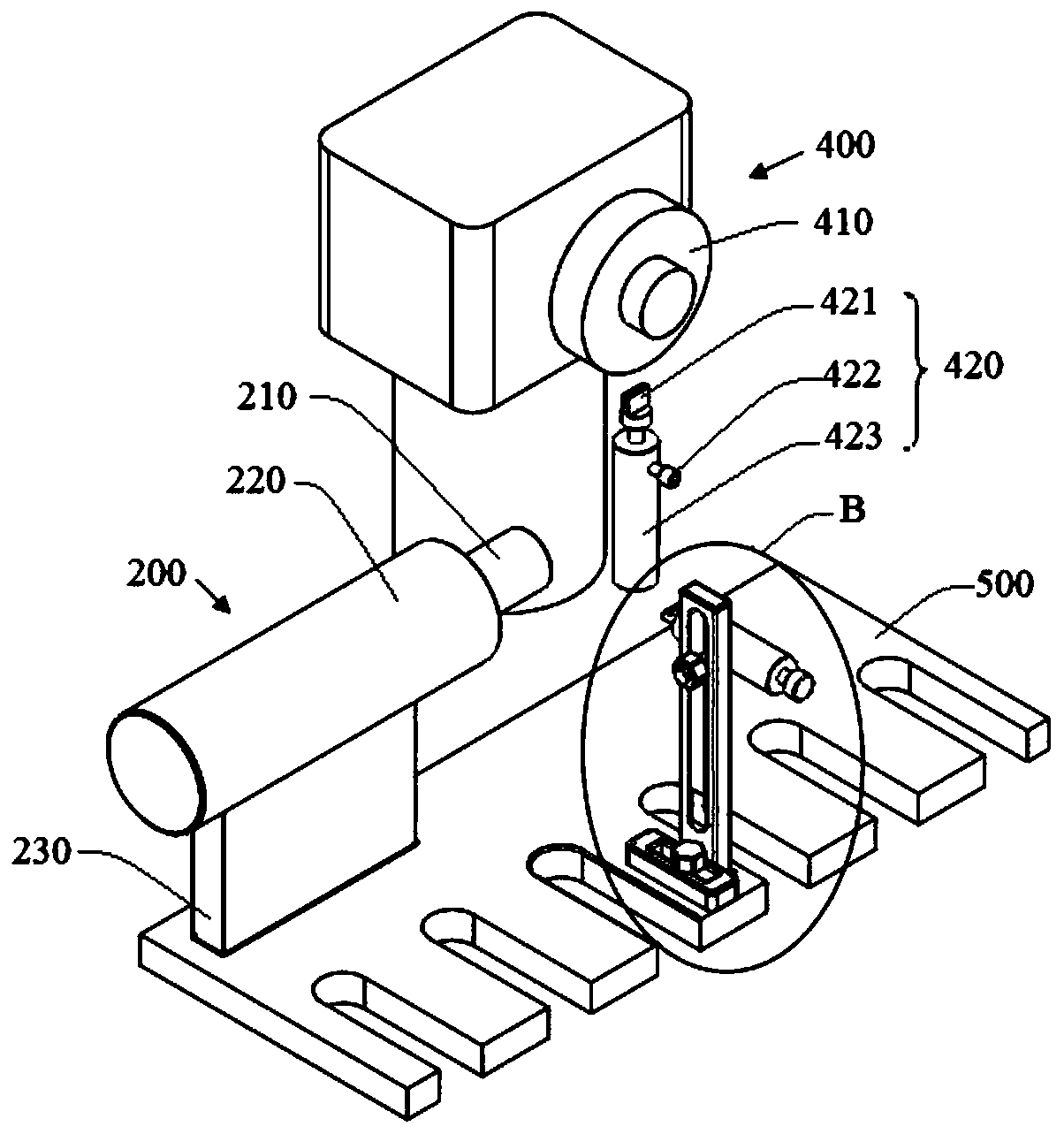

Circular tooth knife for plastic pulverizer and grinding tool and processing technology thereof

ActiveCN110238716AReduce damage rateAffect speedOther manufacturing equipments/toolsGrain treatmentsMechanical engineeringPulverizer

The invention discloses a circular tooth knife for a plastic pulverizer and a grinding tool and a processing technology thereof, and belongs to the technical field of mechanical cutters. The circular tooth knife comprises a cylindrical knife body, n knife teeth are uniformly distributed in the length direction of the periphery of the knife body, n is larger than or equal to 30 and smaller than or equal to 50, a tooth groove is formed between every two adjacent knife teeth, and arc faces are arranged at the edges in the length directions of the groove bottoms of the tooth grooves. The grinding tool comprises a mounting unit, a positioning unit and a grinding unit, the mounting unit is used for supporting the knife body to be processed, the positioning unit is used for limiting rotation of the knife body on the mounting unit, and the grinding unit is used for polishing cutting edge faces of the knife teeth; and the mounting unit is located between the positioning unit and the grinding unit. The processing technology of a round blade is that after linear cutting is carried out, the grinding tool is used for grinding and machining the cutting edge faces. By means of the circular tooth knife, the sharpness of the circular tooth knife can be ensured, the service life can be prolonged, and the cutting edge faces of the knife can be conveniently and accurately ground.

Owner:ANHUI FENGLIRUI BLADE MFG CO LTD

Polyethylene composition for greenhouse film and preparation method of polyethylene composition

InactiveCN108003452AFully dispersedImprove melt strengthCultivating equipmentsGreenhouseThermal insulation

The invention relates to a polyethylene composition for a greenhouse film. The polyethylene composition is prepared from the following raw materials in parts by weight: 100 parts of mLLDPE resin, 0.03to 0.05 parts of peroxide, 6 to 14 parts of maleic anhydride master batch, 0.1 to 0.5 part of antioxidant, 0.04 to 0.07 part of rheological agent, 1 to 1.5 parts of heat preserving additives, and 0.05 to 0.10 part of lubricating agents. The composition has higher melt viscosity, and the prepared greenhouse film has thermal insulation properties.

Owner:淄博赢信达知识产权咨询服务有限公司

Active noise reduction binaural automatic debugging and matching TWS Bluetooth earphone

InactiveCN112243178AEasy to assemble and disassembleSave human effortMicrophonesLoudspeakersHeadphonesNoise reduction

The invention discloses an active noise reduction binaural automatic debugging TWS Bluetooth earphone, and the earphone comprises a TWS Bluetooth earphone charging box; a TWS Bluetooth earphone charging box cover is hinged to the top of the TWS Bluetooth earphone charging box, and the TWS Bluetooth earphone charging box cover and the TWS Bluetooth earphone charging box are clamped together. Opposite TWS Bluetooth earphone charging jacks are formed in the top of the TWS Bluetooth earphone charging box, and the TWS Bluetooth earphone charging box cover is hinged to the top of the TWS Bluetooth earphone charging box, so the top of the TWS Bluetooth earphone charging box is sealed conveniently, and the TWS Bluetooth earphone can be protected, so the TWS Bluetooth earphone is not prone to damage; A TWS Bluetooth earphone charging jack is formed in the top of the TWS Bluetooth earphone charging box, so the TWS Bluetooth earphone can be conveniently inserted into the TWS Bluetooth earphone charging jack, and the TWS Bluetooth earphone can be stored and charged.

Owner:DONGGUAN UIISII ELECTRONICS CO LTD

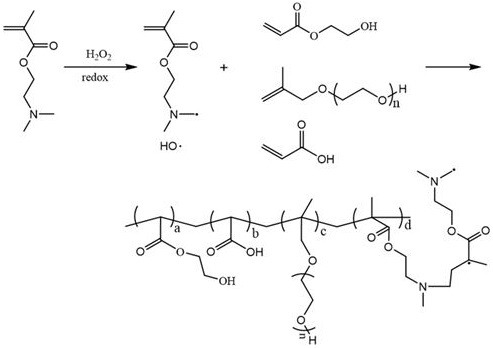

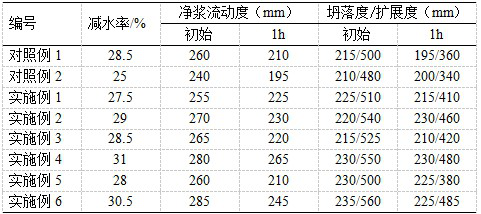

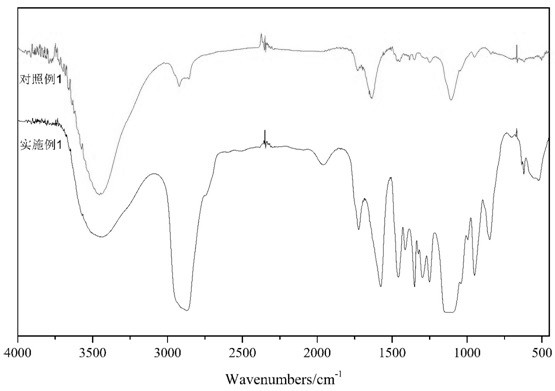

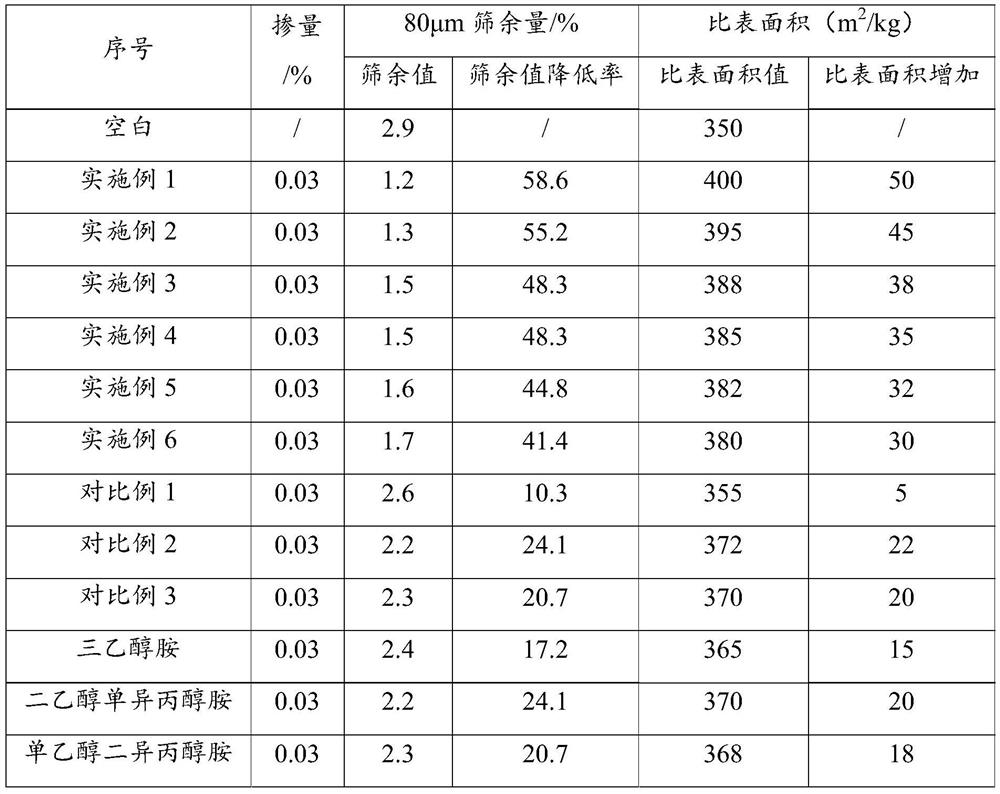

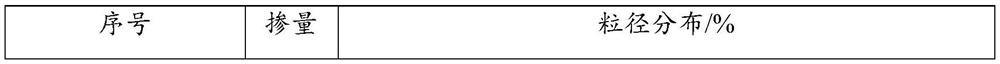

Hyperbranched solid polycarboxylate superplasticizer and preparation method thereof

Owner:JINAN URBAN CONSTR GRP

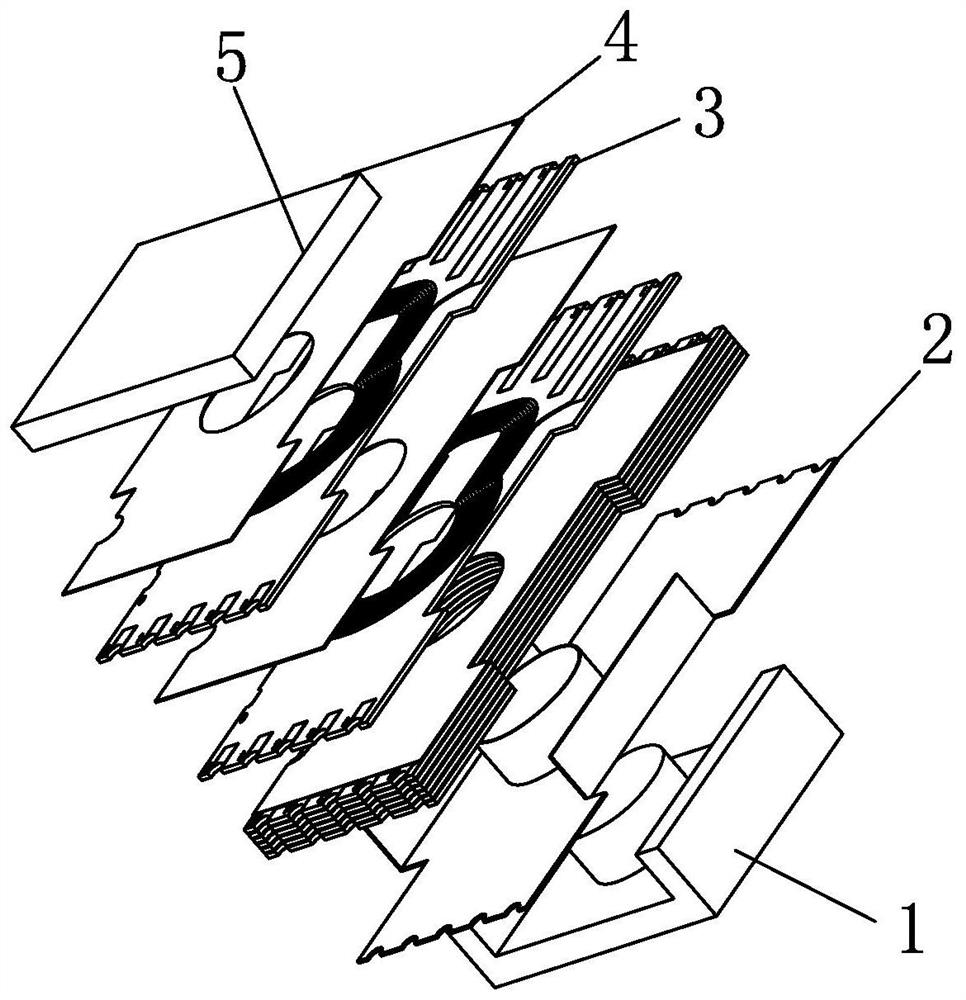

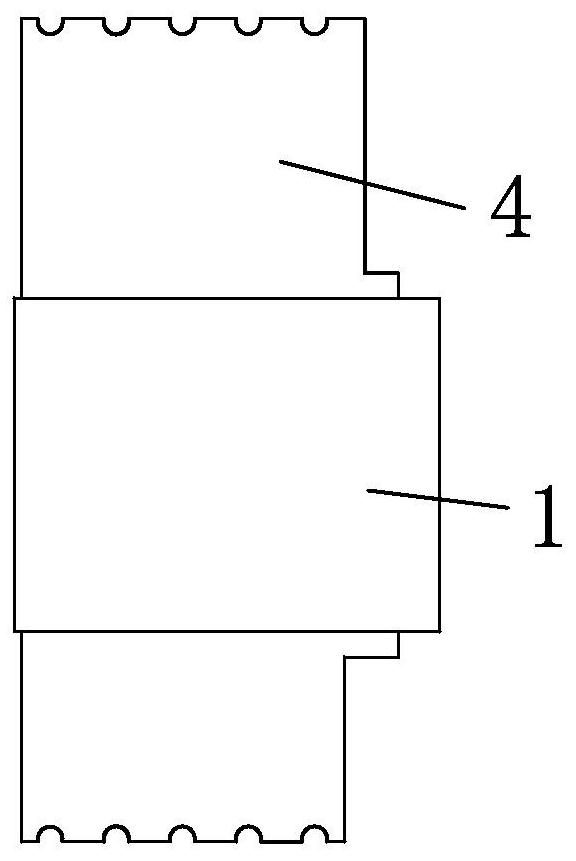

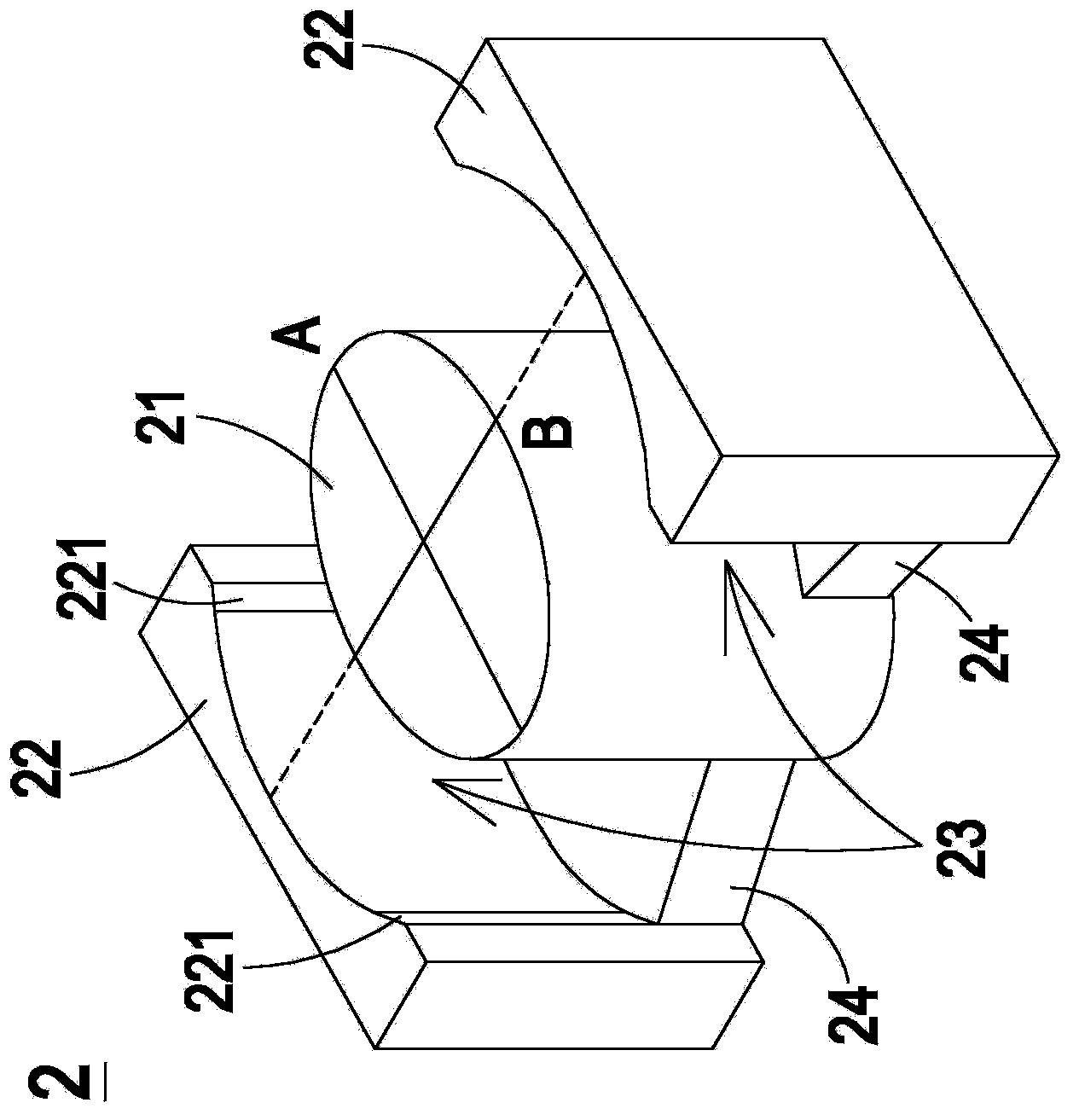

Layered stacking type high-performance electronic transformer and implementation method thereof

PendingCN112786290AIncrease flexibilityIncrease cooling areaTransformers/inductances coolingTransformers/inductances coils/windings/connectionsThermodynamicsTransformer

The invention relates to the technical field of electronic components, and discloses a layered stacking type high-performance electronic transformer and an implementation method thereof. The layered stacking type high-performance electronic transformer comprises a lower magnetic core, and a framework is installed at the top of the lower magnetic core; a PCB is installed at the top of the framework, an insulating sheet is installed at the top of the PCB, an upper magnetic core is installed at the top of the insulating sheet, and the upper magnetic core and a lower magnetic core are fixed in a contact mode; each layer of coil is stacked in a parallel mode, so that the number of stacked layers can be adjusted and matched according to needs of users, flexibility is high, meanwhile, reserved gaps exist between the coils, heat is not concentrated, layered heat dissipation is achieved, the heat dissipation area and heat dissipation channels are large, and temperature rise is reduced; after the novel parallel groove rack is adopted, the creepage distance and the insulating and voltage-resisting effects are good, heat accumulation is avoided, heat dissipation is not easy, the problem of poor performance consistency caused by irregular forms is solved, and the heat dissipation performance, the flexibility and the performance consistency of the device are improved.

Owner:深圳市柔性磁电技术有限公司

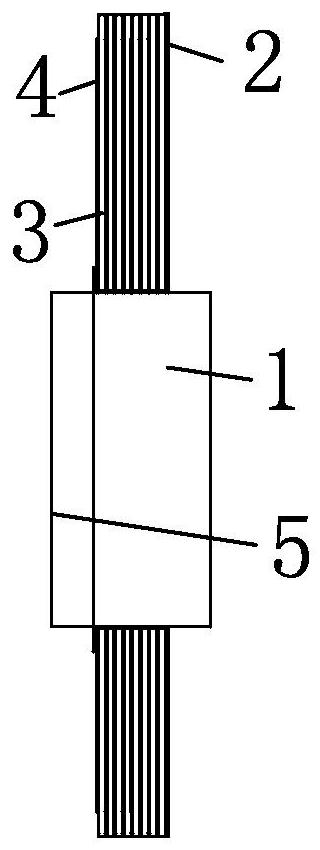

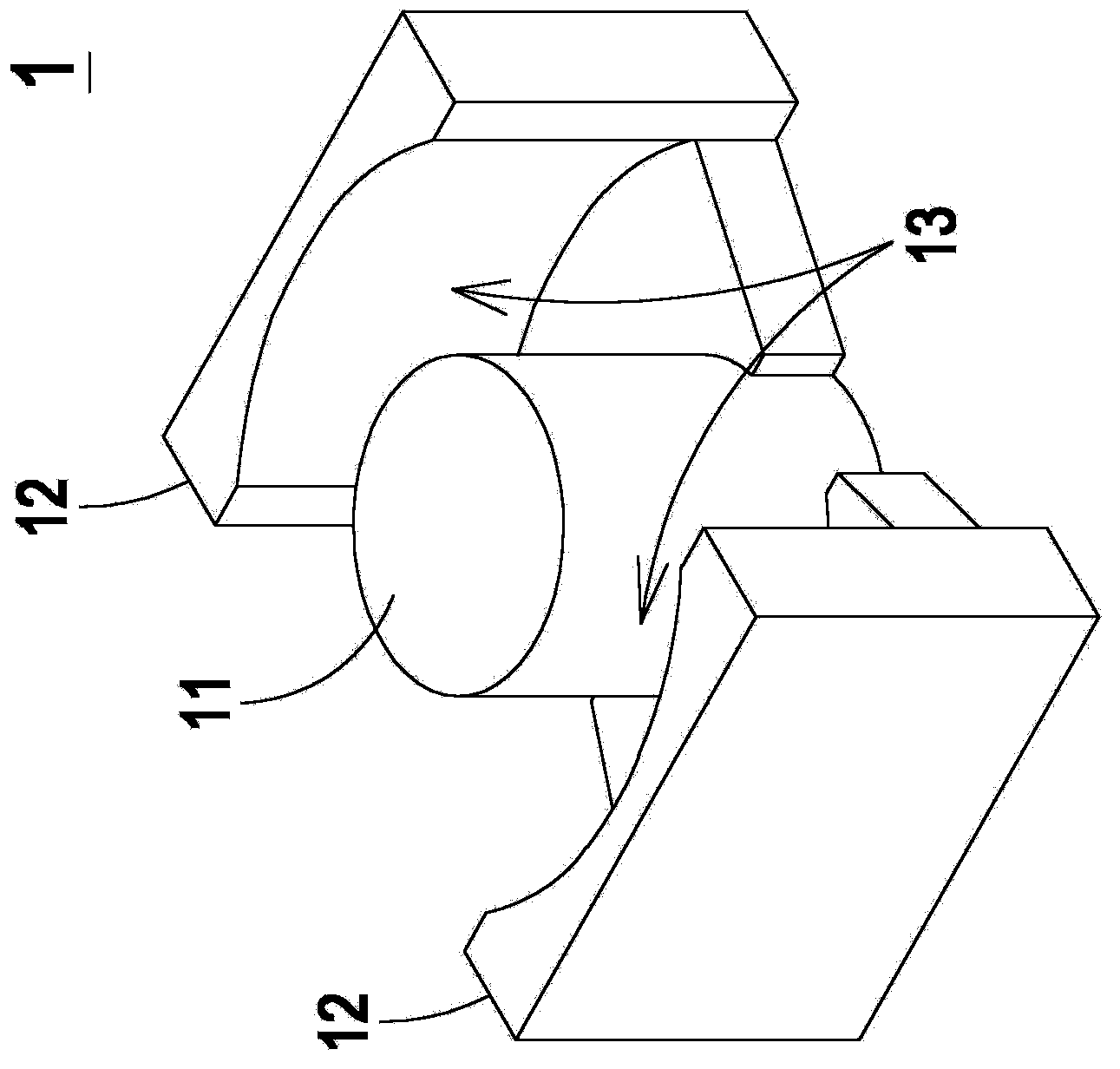

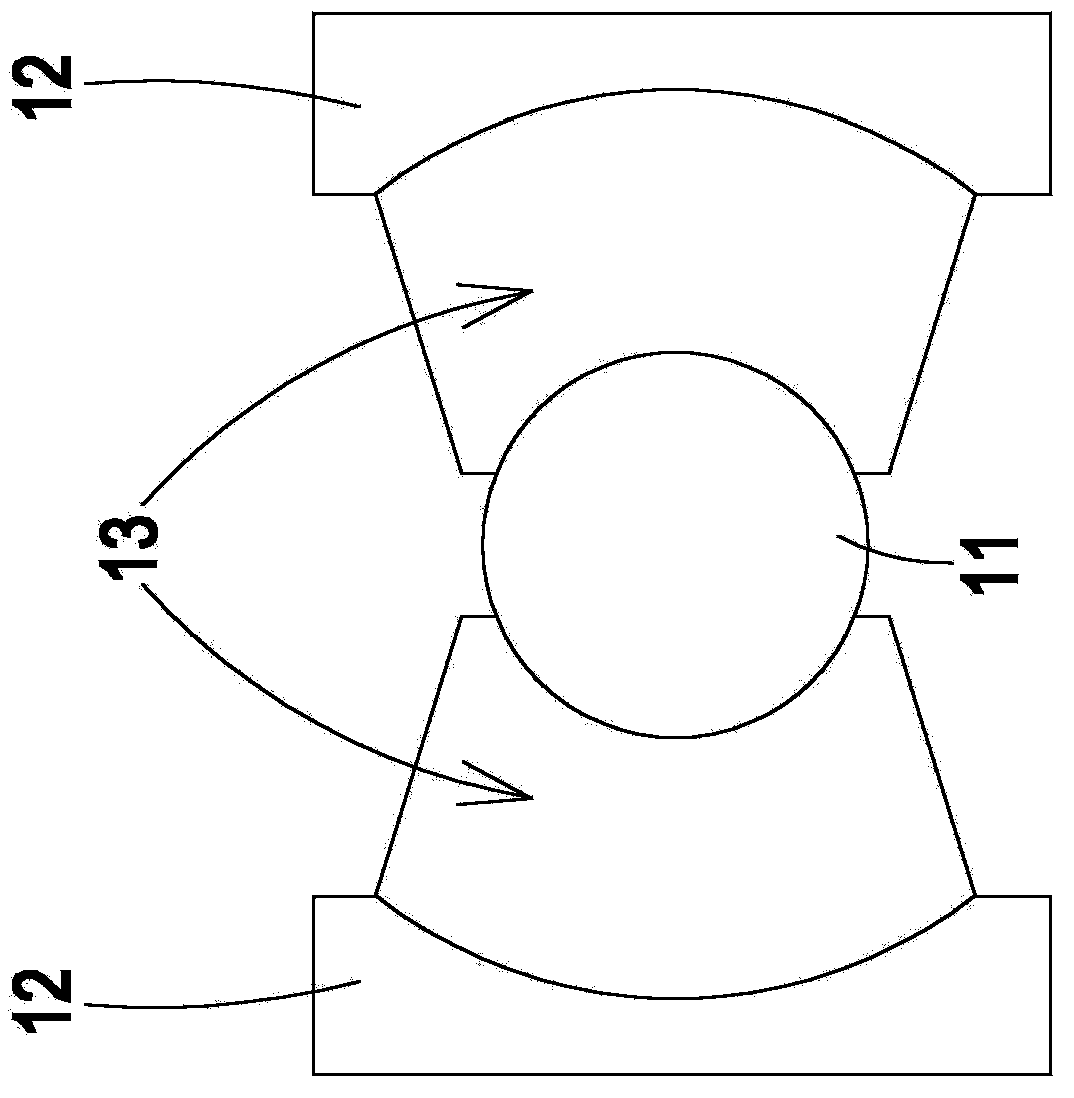

Magnetic core and applicable magnetic element of magnetic core

InactiveCN104252951ASmall diameterSave space for windingTransformers/inductances magnetic coresInductance with magnetic coreLong axisSafety specification

The invention discloses a magnetic core and an applicable magnetic element of the magnetic core. The magnetic core at least comprises an oval center post and two side posts, wherein the oval center post is provided with a long shaft and a short shaft; the length of the long shaft is greater than that of the short shaft; the two side posts are oppositely arranged at two sides of the oval center post, are connected with the oval center post, and define at least one winding space together with the oval center post. Through the arrangement of the oval center post, the magnetic core has the advantages that the winding space is enlarged, the diameter of a wining coil is increased, the temperature of a winding solenoid is lowered, the winding solenoid is prevented from being oversize, and the safety distance between the winding solenoid and a reel is increased to accord with the safety specification.

Owner:DELTA ELECTRONICS INC

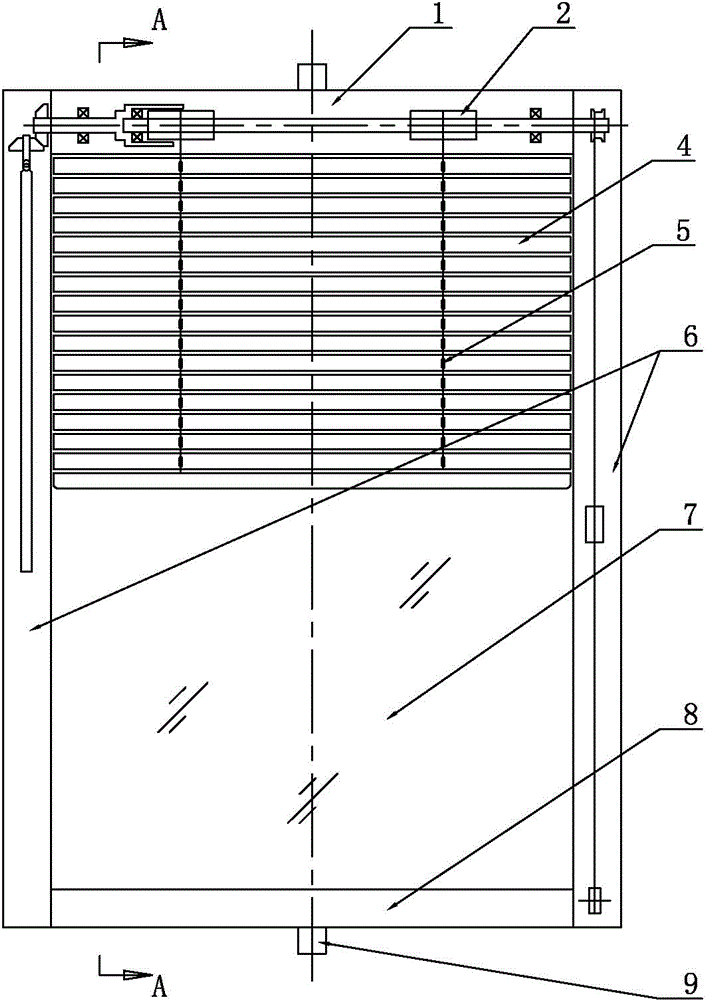

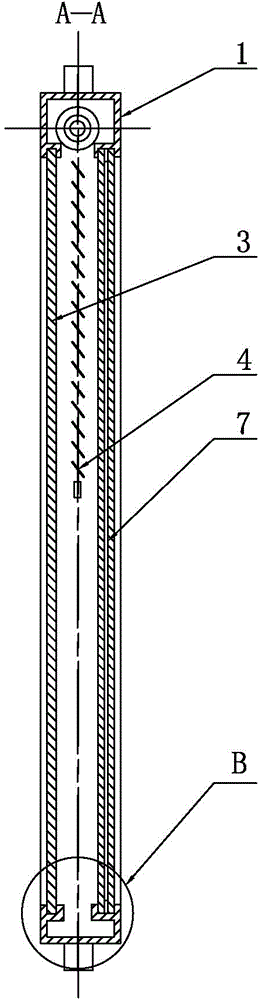

Composite vacuum glass with built-in shutters, and use method of composite vacuum glass

ActiveCN102839903BDifficult to penetrate through vacuum glassPenetration will notDoor/window protective devicesWindow shutterEngineering

The invention discloses a composite vacuum glass with built-in shutters in the technical field of windows and a use method of the composite vacuum glass with built-in shutters. The device comprises a window frame which is surrounded by an upper frame, a bottom frame and two side frames; two glasses are arranged in the window frame in parallel; shutters are arranged between the two glasses; the upper frame is internally provided with a winding mechanism; one of the two glasses is a vacuum glass which comprises an outer-layer glass and an inner-layer glass; a vacuum cavity is arranged between the outer-layer glass and the inner-layer glass and is internally provided with a plurality of supporting columns between the outer-layer glass and the inner-layer glass; and the peripheries of the outer-layer glass and the inner-layer glass are sealed by edge-sealing solders. The device uses a vacuum glass structure to combine with shutters, uses good sound insulation and heat insulation performances of the vacuum glass and matches with the light-shielding performance of the shutters, so that the device has good heat insulation effect. The device is good in sound insulation, capable of shielding sunlight and regulating light by opening and closing the shutters and can be used by differentiating seasons and areas.

Owner:YANGZHOU UNIV

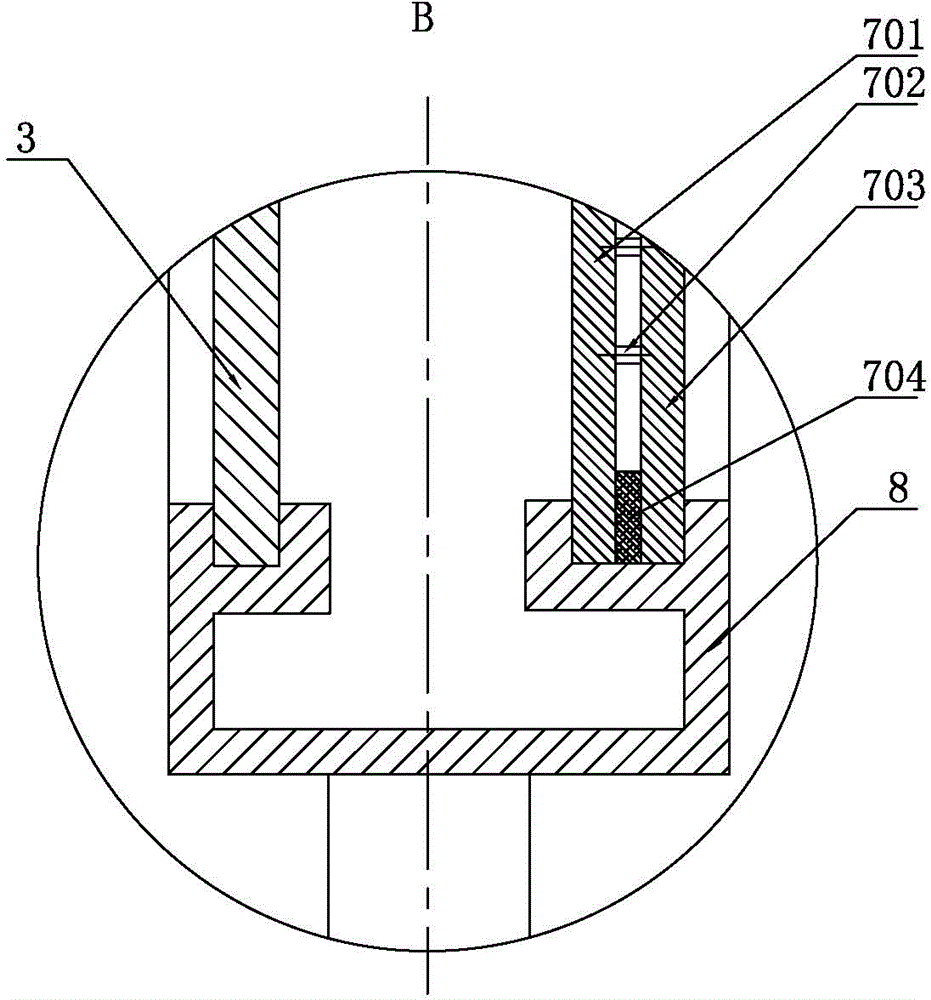

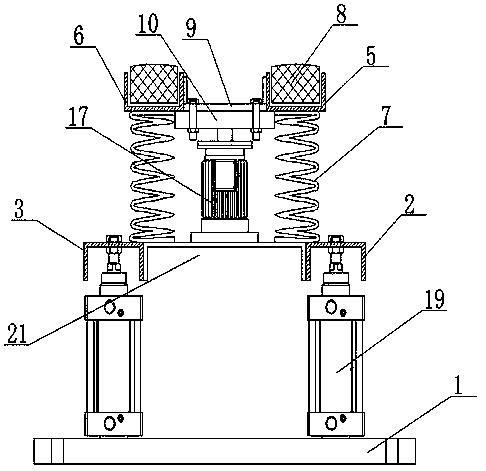

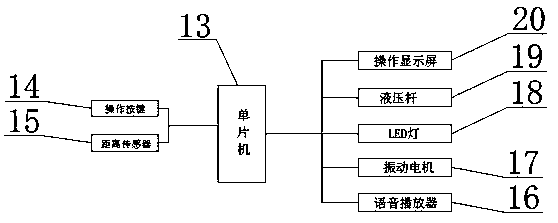

Vibrating device for cake production line

PendingCN109349289ANot easy to shrinkDoes not affect processingBaked articles handlingProduction lineElectric control

The invention provides a vibrating device for a cake production line. The vibrating device comprises a base, first supporting channel steel, second supporting channel steel, an electric control box and an intelligent processing system; a supporting plate is welded between the first supporting channel steel and the second supporting channel steel, a mounting groove is formed in the bottom of the supporting plate, damping springs are welded to the bottoms of the two ends of first vibrating channel steel and the bottoms of the two ends of second vibrating channel steel, the other ends of the damping springs are welded to the top of the supporting plate, rubber buffering pads are mounted in the first vibrating channel steel and the second vibrating channel steel, a connecting frame is welded between the first vibrating channel steel and the second vibrating channel steel, a fixing plate is fixedly welded to the bottoms of the first vibrating channel steel, the second vibrating channel steel and the connecting frame, a power line is connected to the rear side of the electric control box, and the electric control box is fixedly mounted at the top of the base. The vibrating device for thecake production line is reasonable in design and high in adaptability, and can effectively improve the cake processing quality and processing efficiency.

Owner:蔡井辉

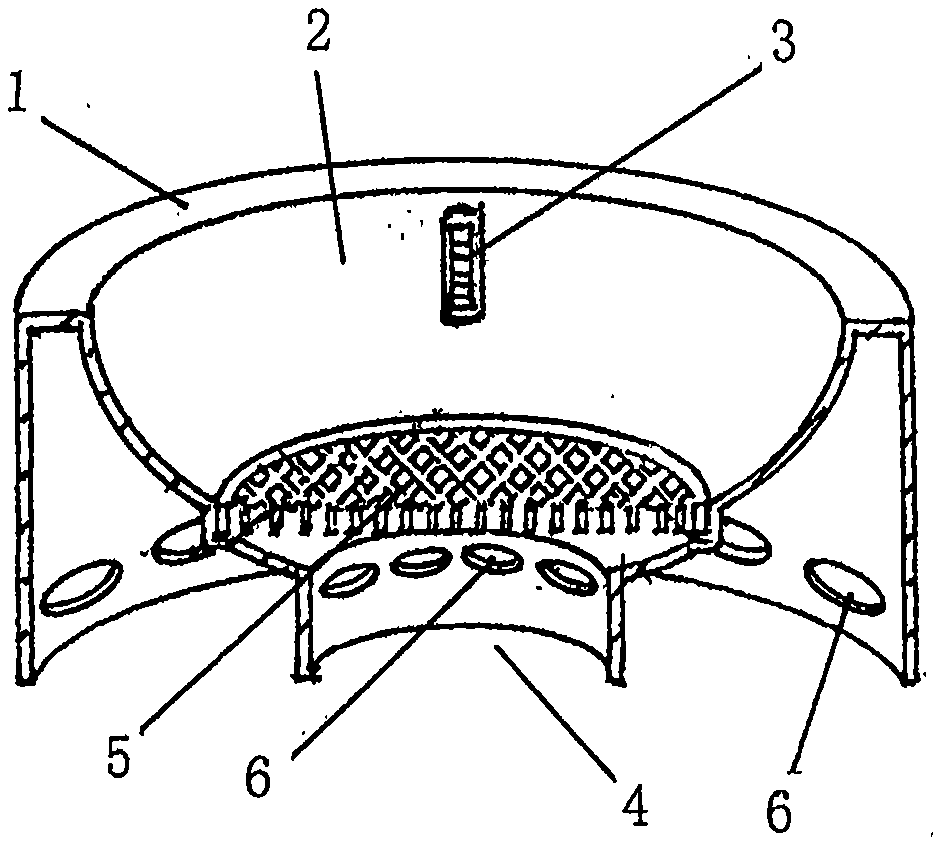

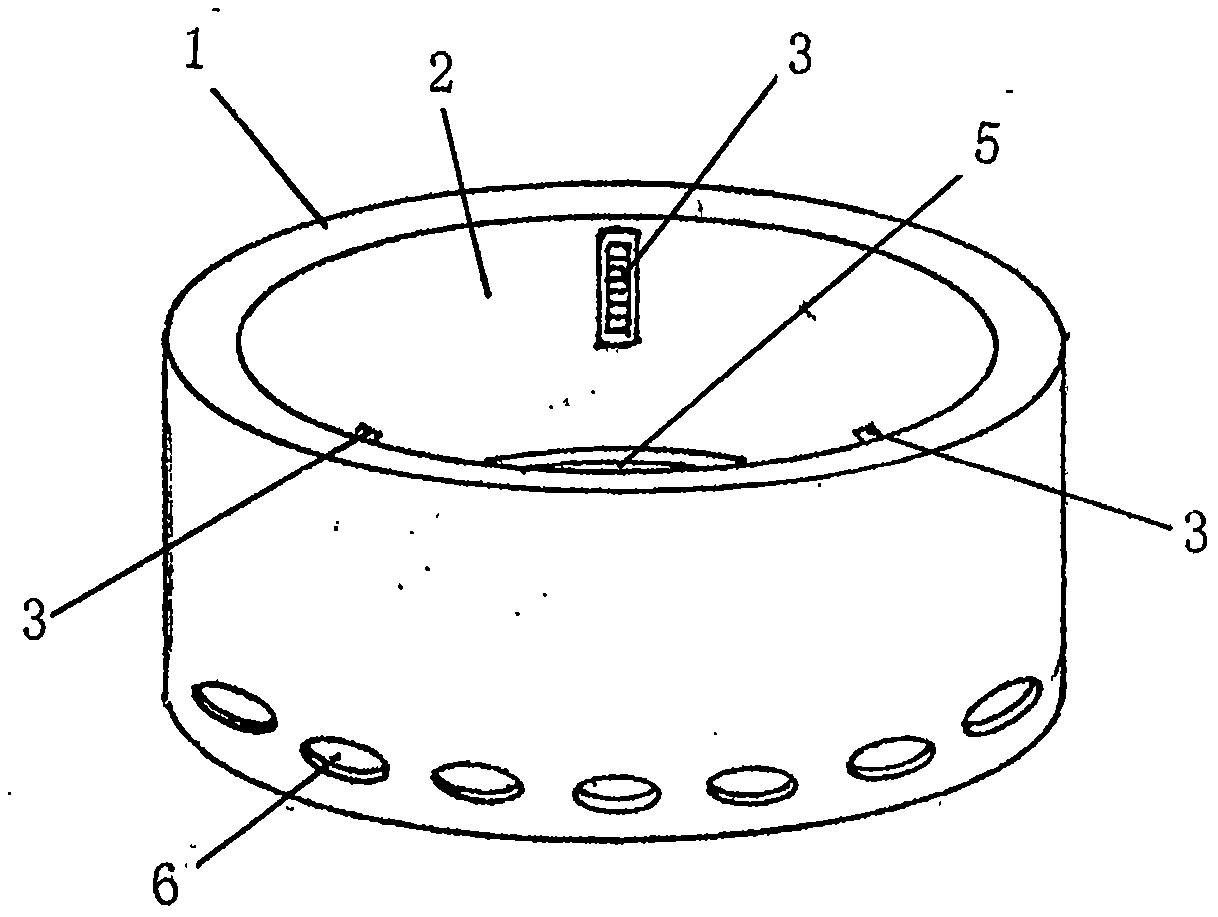

Gas range burner energy saving cover

PendingCN107796022ASolve the problem of energy savingSolve the problem of waste caused by heat energy dissipating aroundDomestic stoves or rangesLighting and heating apparatusThermodynamicsHoneycomb

The invention provides a gas range burner energy saving cover which is characterized in that in the gas range burner energy saving cover which can sleeve a gas range burner for use, a sunken circulargroove which is fitted with and corresponds to a pan bottom is formed in the middle of a cover body; a plurality of reversed-T-shaped blocks jacking the pan bottom are arranged at the periphery of thecover body; a burner ferrule is arranged in a space below the middle of the circular groove; an enlarged honeycomb secondary burning disc is arranged in a space above the middle of the circular groove; and a plurality of secondary air inlets are formed in the peripheries of the lower parts of the cover body and the circular groove. Thus, when the gas range burner energy saving cover sleeves the gas range burner for use, flames can be gathered at the pan bottom and the pan bottom can absorb heat, and with the adoption of the secondary burning disc additionally, when smoke generated due to primary burning of the gas range burner rises, reburing is carried out through oxygen supplementation by secondary air, and sufficient burning the improvement of the heat energy efficiency are facilitated.

Owner:潘明珠

Polycarboxylic acid polymer, preparation method and application thereof

The invention belongs to the technical field of building material preparation, and particularly relates to a polycarboxylic acid polymer, a preparation method and application thereof. The method comprises the following steps: (1) adding a polymerization inhibitor and part of unsaturated carboxylic acid into molten unsaturated polyether to form a mixed solution A; (2) preparing a mixed solution B from an esterification monomer and the residual unsaturated carboxylic acid; and (3) adding the mixed solution B into the mixed solution A, and performing bulk polymerization under the action of an initiator to obtain a polycarboxylic acid polymer, wherein in the step (3), inert gas is introduced in the early stage of the reaction, oxygen is introduced in the middle stage of the reaction, and inert gas is introduced in the later stage of the reaction. According to the invention, when the method is used for preparing the polycarboxylic acid polymer, the viscosity of a reaction system can be well controlled, the reaction rate is improved, the whole reaction process is stable, the molecular weight of the obtained polymer is narrow, and the effective content is increased; and the polycarboxylic acid polymer is used as a cement grinding aid, so that the grinding aid has good grinding aiding effect, water-reducing rate and early strength performance, and a solvent does not need to be added in the use process.

Owner:JIAHUA CHEM TECH DEV SHANGHAI CO LTD

Cooling type transformer

ActiveCN114093602ARemove and clean up in timeDifficult to remove and cleanTransformers/inductances coolingDispersed particle filtrationCatkinTransformer

The invention discloses a cooling type transformer which comprises a shell, a ceiling and a cover shell, a transformer body is arranged in the center of the interior of the shell, an air inlet is formed in the bottom of the surface of the shell and located in the position of the cover shell, and a heat dissipation device is arranged at the bottom of the inner wall of the shell. A driving mechanism is arranged in the center of the bottom of the inner wall of the shell and connected with the heat dissipation device in a matched mode, a impurity filtering device is arranged at the bottom of the surface of the shell and located at the air inlet, an air outlet is formed in the top of the shell, and a filter screen is arranged between the two corresponding sides of the inner wall of the ceiling and the top of the surface of the shell. The invention relates to the technical field of power electrical equipment. According to the cooling type transformer, the effects of impurity removal and heat dissipation are achieved, insects, catkins and other impurities can be removed and cleaned in time, the insects, the catkins and other impurities are not prone to entering equipment, then impurity accumulation is effectively prevented, heat dissipation is conducted on the equipment in time, the high temperature situation is not prone to occurring, the service life of the equipment is prolonged, safety and reliability are achieved, and the use performance is improved.

Owner:江苏天瑞变压器有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com