Collector plate of fuel cell as well as preparation method thereof

A fuel cell and collector plate technology, which is applied to fuel cell parts, fuel cells, circuits, etc., can solve the problems of large size, inconvenient processing, thick thickness, and increased weight of the stack, so as to facilitate rapid assembly and market prospects Broad, the effect of improving the performance of the stack

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

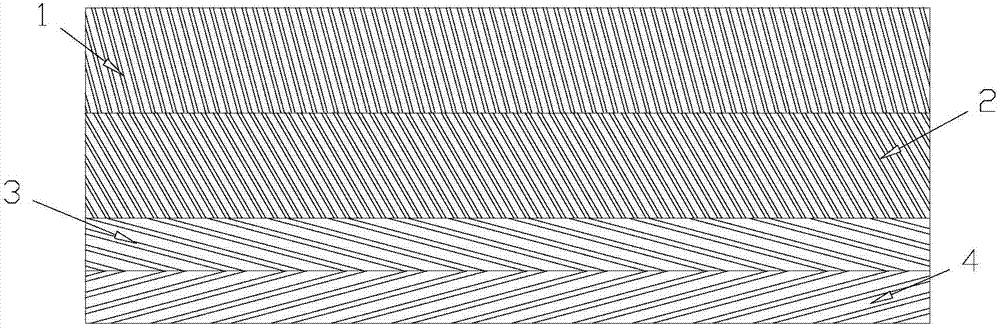

[0026] Such as figure 1 As shown, a collector plate of a fuel cell includes a base plate 2, a metal foil layer 3, a coating layer 1 and a gold-plated layer 4, the base plate 2 is a non-metal base plate, and one side of the base plate 2 Coated with a coating layer 1, the other side of the base plate 2 is provided with a metal foil layer 3, and the other side of the metal foil layer 3 is plated with a gold-plated layer 4.

[0027] Wherein, the connection method between the base plate 2 and the metal foil layer 3 is pasting, and the connection method between the metal foil layer 3 and the gold-plated layer 4 is electroplating.

[0028] The thickness of the substrate plate 2 is 1.5mm, and the material of the substrate plate 2 is polypropylene, which is light in weight and easy to form, and has strong heat resistance, which is beneficial to the heat dissipation of the fuel cell. The metal foil layer 3 is made of stainless steel foil, and the thickness of the stainless steel foil l...

Embodiment 2~5

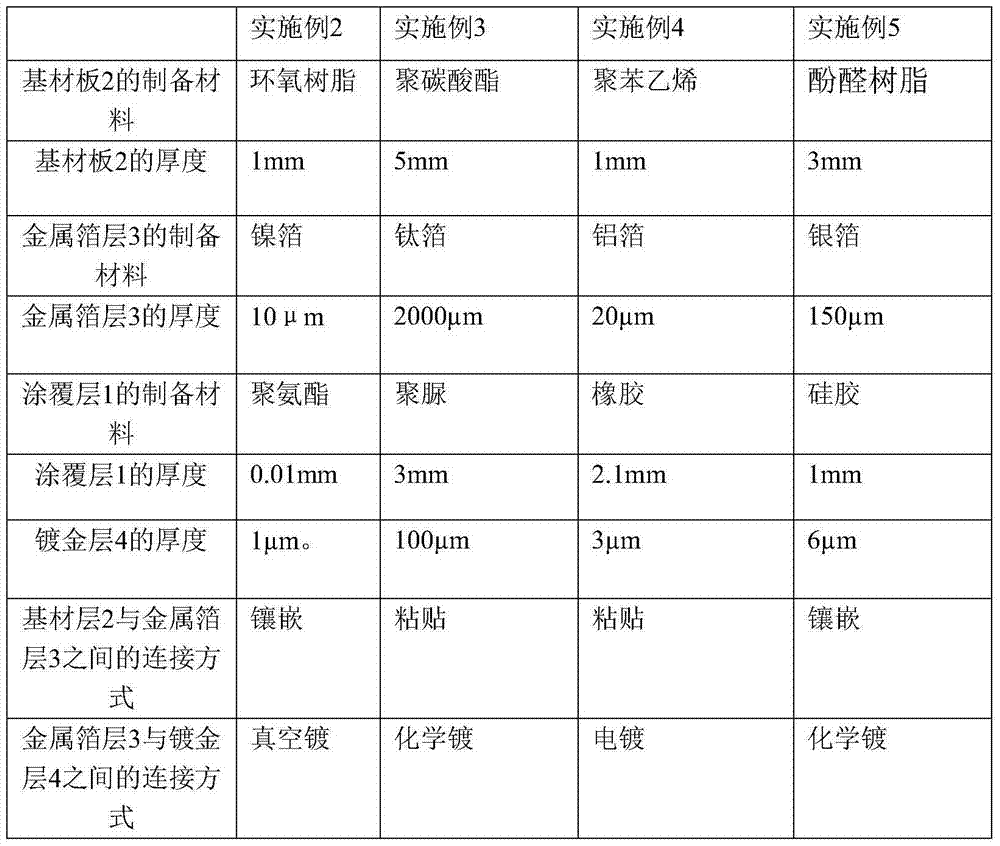

[0036] A collector plate for a fuel cell, the structure of which is the same as in Example 1, including a substrate plate 2, a metal foil layer 3, a coating layer and a gold-plated layer 4, the differences are shown in Table 1:

[0037]

[0038] The performance of the collector plate prepared in Example 2 is similar to that of the collector plate prepared in Example 1, but due to the different thickness of the substrate plate 2, the weight is lighter, the mechanical properties are slightly worse, and the heat dissipation performance is not as good as that of Example 1. , but the electrochemical stability is relatively good after using nickel foil

[0039] The performance of the collector plate prepared in Example 3 is similar to that of the collector plate prepared in Example 1, the electrical conductivity is almost the same, and the shock absorption performance, heat dissipation performance and sealing performance are not as good as those of Example 1. The base material of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com