Low-temperature non-combustion fLue-cured tobacco heating device, system and method

A low-temperature non-combustible, heating device technology, applied in tobacco, smokers' supplies, applications, etc., can solve the problems of easy diffusion of heating pipes, uneven baking, and short smoking time, so as to avoid excessive temperature, scald the mouth, and discharge The smoke speed is fast and the effect of reducing the contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The present invention will be further described in detail with an embodiment below, but it should be noted that the protection scope of the present invention is not limited thereto.

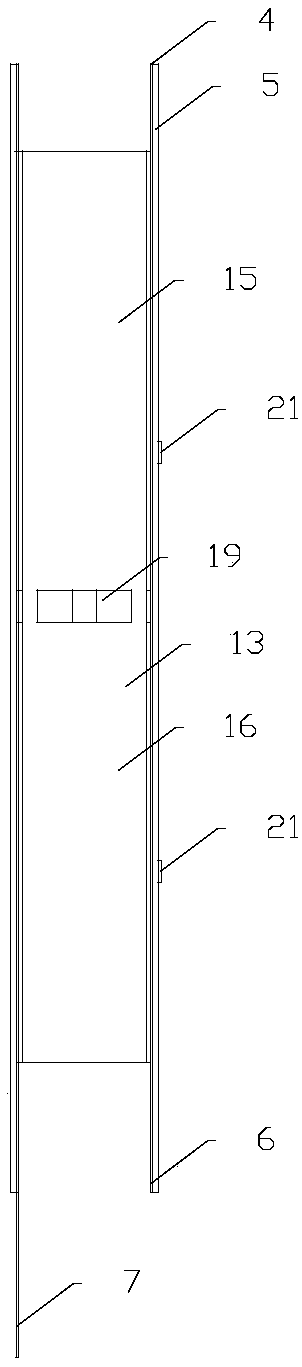

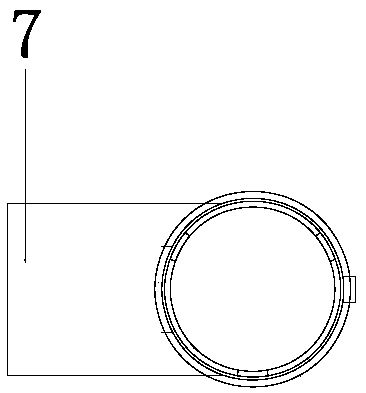

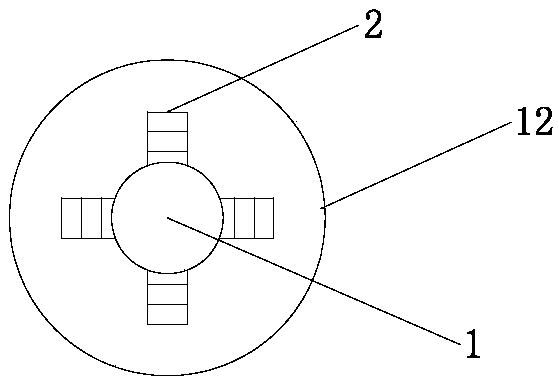

[0042] Such as Figure 1-8 As shown, a low-temperature non-combustion flue-cured tobacco heating device includes a smoking port 1, a smoking port connector 12, a heating pipe 13, an air inlet connecting member 14 and an air inlet 11 from top to bottom, and also includes a heating pipe 13 The circuit-connected PCBA, and the MCU located on the PCBA, and the thermistor 21 connected to the MCU; the heating pipe 13 includes a metal tube, a heating film 4 and a heat shrinkable sleeve 5 from the inside to the outside, and the heating film 4 is provided with a heating element 20, the heat-shrinkable sleeve 5 is used to fix the heating film 4, the heating film 4 is divided into a first heating film 17 and a second heating film 18, and the heating film 4 is heated by Membrane leads 7 are directly c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com