Compound machine glue tank heat preservation device

A technology of heat preservation device and temperature measurement device, which is applied to devices and coatings that apply liquid to the surface, can solve the problems of easy heat dissipation, preheating, poor heat preservation effect, etc. good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

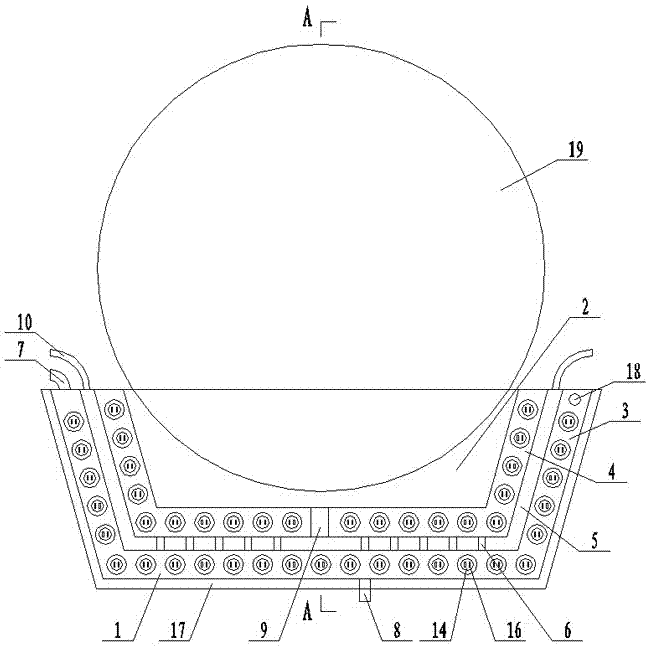

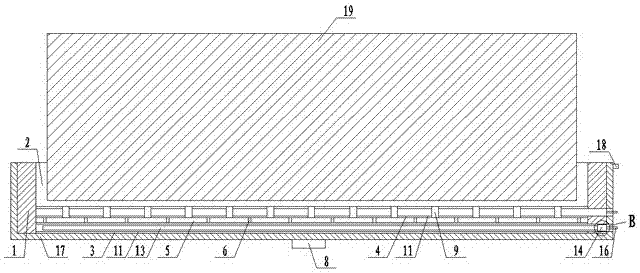

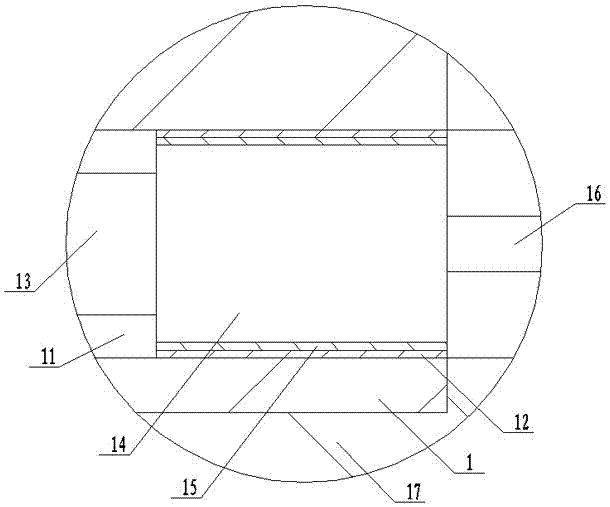

[0010] The specific content of the present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0011] Such as figure 1 , figure 2 , image 3 As shown, the thermal insulation device of the compound machine glue tank includes: a base 1 and a U-shaped glue tank 2 arranged in the base 1, and an outer U-shaped heat transfer oil chamber 3 and an inner U-shaped heat transfer oil chamber are respectively arranged inside the base 1 Cavity 4, a U-shaped colloid preheating chamber 5 is provided in the base 1 between the U-shaped heat-conducting oil chamber 3 and the inner U-shaped heat-conducting oil chamber 4, and the outer U-shaped heat-conducting oil chamber 3 and the inner U-shaped heat-conducting oil chamber The middle part of the lower end of the oil chamber 4 communicates with each other through a number of heat transfer oil connecting pipes 6 arranged in the U-shaped colloid preheating chamber 5 , and the base 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com