Manufacturing method of magnesium chloride discharge pipe of reactor for producing sponge titanium

A production method and magnesium chloride discharge technology, which is applied in the field of non-ferrous metal smelting equipment, can solve the problems of increased power consumption, magnesium chloride and magnesium clogging of magnesium chloride horizontal pipes, and long time occupation, so as to reduce the probability of clogging, ensure product quality, and prolong service life. The effect of longevity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

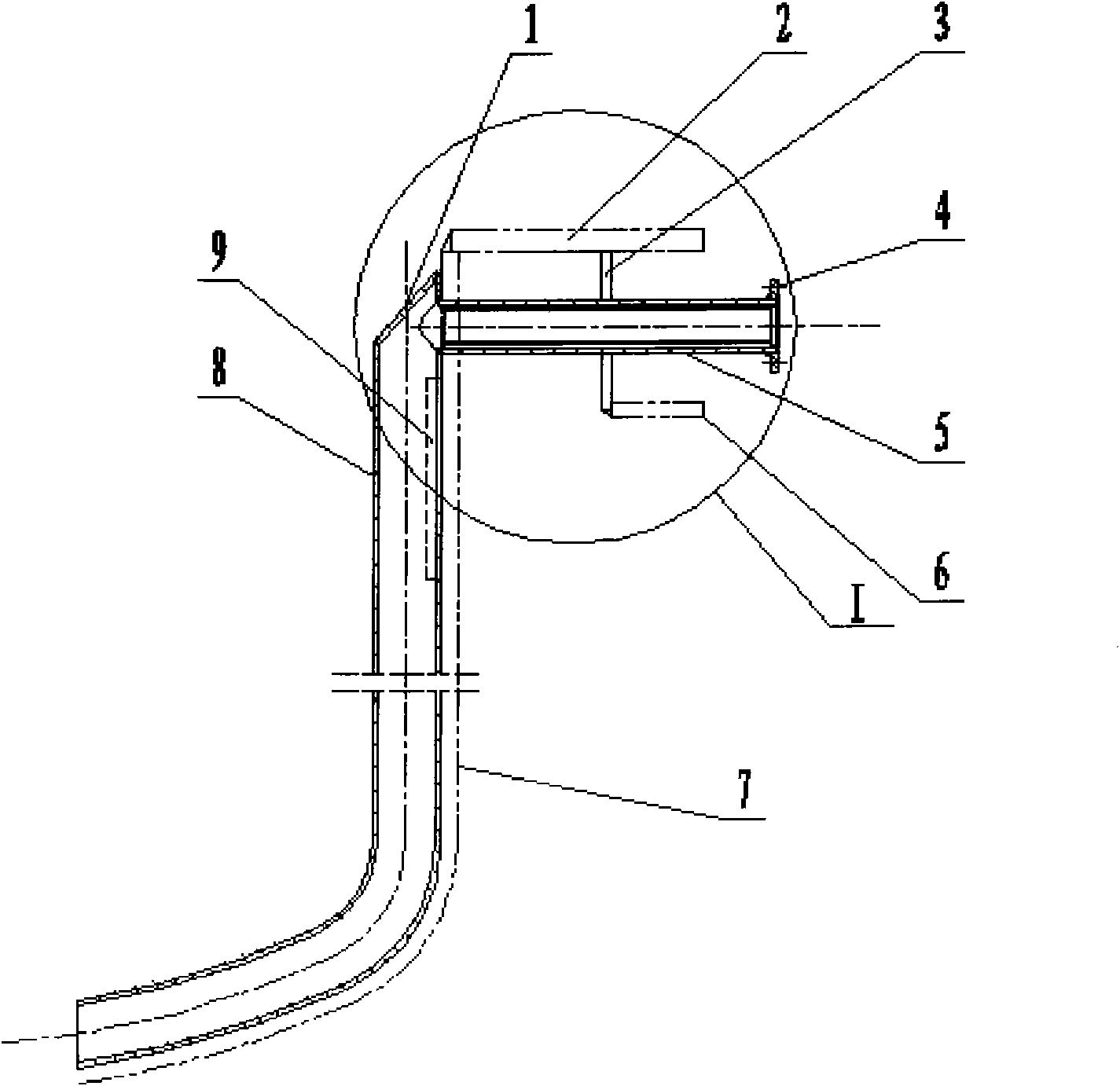

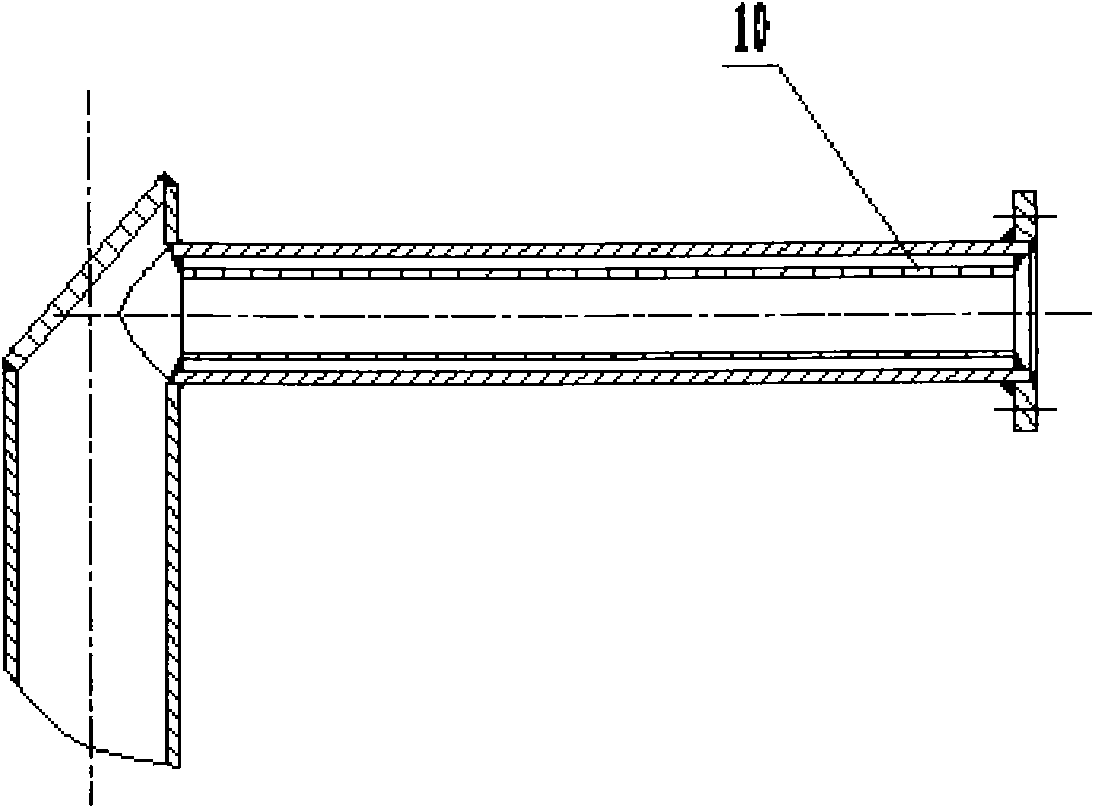

[0019] Such as figure 1 and figure 2 As shown, the row magnesium chloride tube of the present invention adopts the magnesium chloride row horizontal tube 5 with a diameter of 108mm and the inner sleeve pipe 10 of the row magnesium chloride horizontal tube 10 with a diameter of 76mm to ensure that there is a gap of 6mm between the two, and then one end is spot welded , one end is not to be soldered. After the welding is completed, the whole body and the row of magnesium chloride standpipe 8 are continuously welded and pressed figure 1 As shown, it is welded to the cylinder body 7 through the rib plate, the blocking plate 1 is covered, and the magnesium chloride row flange 4 is installed. It should be noted that it is necessary to ensure that the welds between the magnesium chloride row horizontal pipe 5 and the upper and lower flange short cylinders 3 and the reactor cylinder 7 are continuously welded to ensure airtightness. The magnesium chloride row pipe made by this meth...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com