Gas range burner energy saving cover

An energy-saving hood and gas stove technology, which is applied to household stoves, heating fuels, household stoves/stoves, etc., can solve problems such as waste, and achieve the effect of solving waste and designing scientifically.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

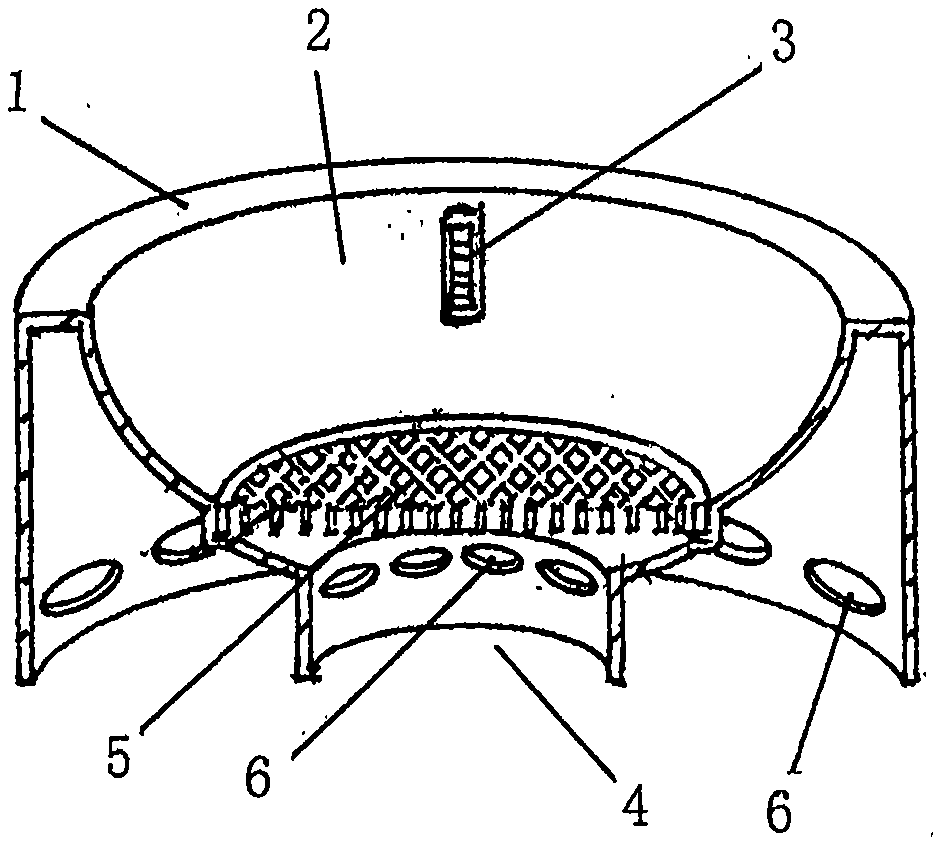

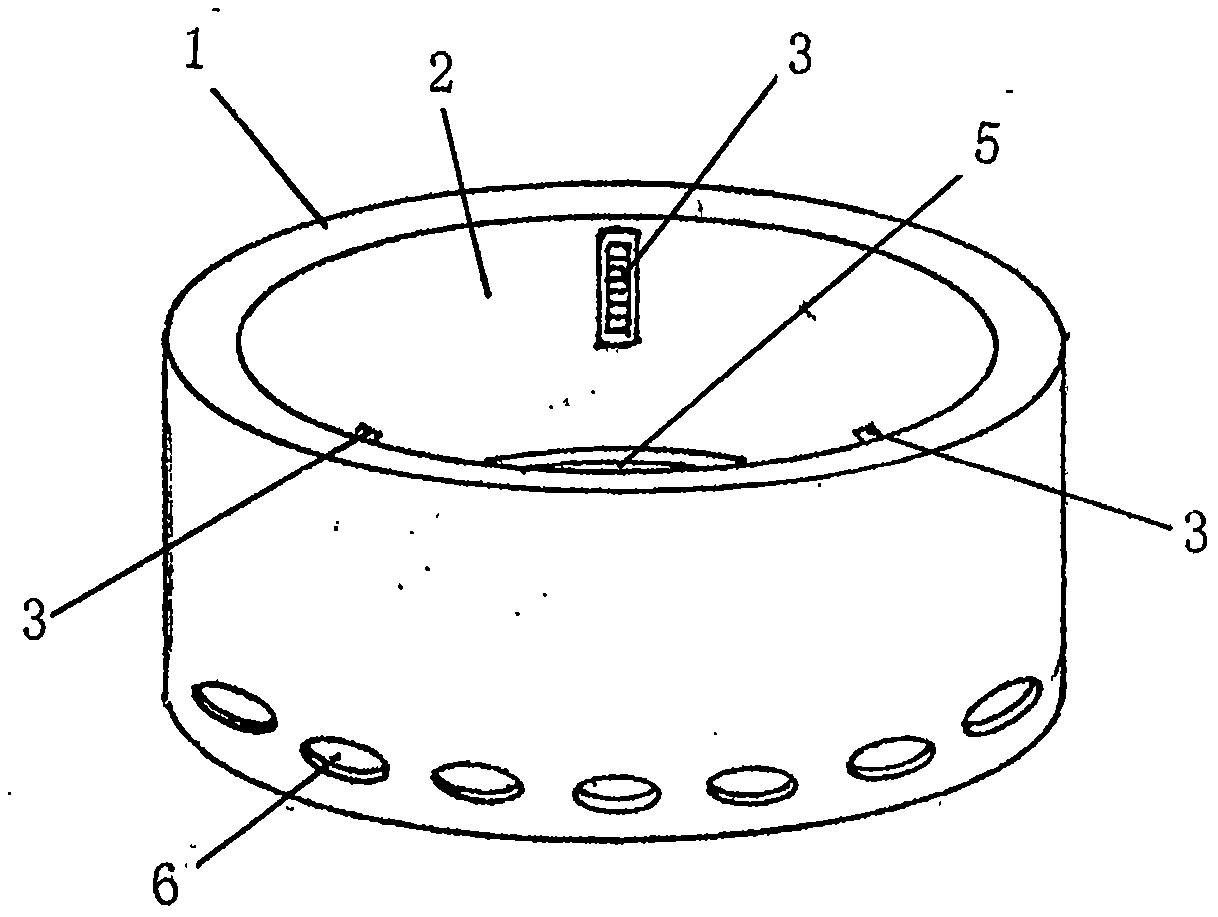

[0009] figure 1 , 2 As shown: the energy-saving cover that can be used on the stove mouth of the gas stove. In the middle of the cover body 1, there is a concave circular groove 2 corresponding to the bottom of the pot, and several protrusions 3 are distributed around it to lift the bottom of the pot; Below the middle of the circular groove 2, there is a furnace mouth ring 4, above which there is an enlarged honeycomb secondary combustion plate 5, and a plurality of secondary air inlets 6 are distributed around the cover body 1 and the lower part of the circular groove 2.

[0010] During specific implementation, the circular groove 2 in the middle of the cover body 1 can be designed as a metal material with good luminosity, so that it can better reflect heat energy and be absorbed by the bottom of the pot through luminosity.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com