Full-automatic crop straw powder preparation system

A technology for crop straw and preparation system is applied in the field of crop straw crushing device, which can solve the problems of large volume and small proportion of straw powder, and achieve the effects of low energy consumption, improved classification accuracy, and reduced internal circulation load.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

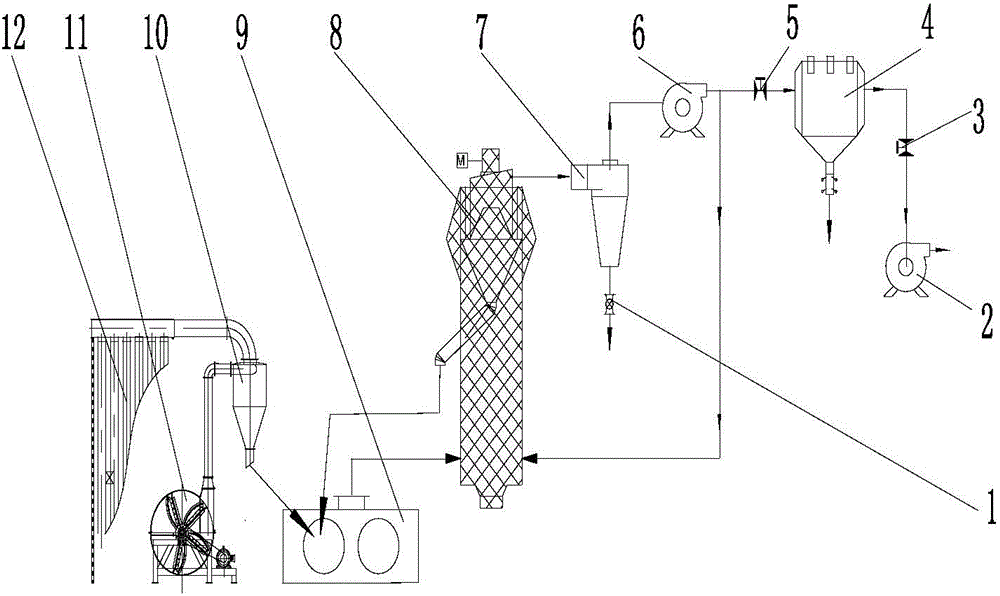

[0010] One embodiment of the present invention is as shown in the accompanying drawings of the description. The system consists of a cutting dust collector 12 connected in sequence, a cutting machine 11, a storage bin 10, a cutting mill 9, a powder separator 8, and a cyclone with an unloader 1. The collector 7, the circulation fan 6 with the circulation air valve 5, the dust collector 4 with the dust collector fan valve 3 and the dust removal fan 2 are composed, and the automatic preparation process of plant fiber powder is realized in this system. During the implementation of the system, the cutting machine 11 realizes the cutting of crop straws, the mill 9 realizes the crushing of plant fiber straws, the powder separator 8 realizes the sorting of plant fiber powders, the cyclone collector 7 realizes the collection of plant fiber powders, and the circulation fan 6 is used for Control the circulating air volume of the system, and blow the ground plant fiber powder from the bott...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com