Thermal insulation energy-saving type boat hull paint and preparation method thereof

An energy-saving, hull technology, applied in the field of coatings, can solve the problems of heat dissipation of the hull, unfavorable energy saving and environmental protection, poor thermal insulation and energy saving of coatings, etc., and achieve the effects of improving thermal insulation and energy saving, not easy to dissipate heat, and reducing speed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

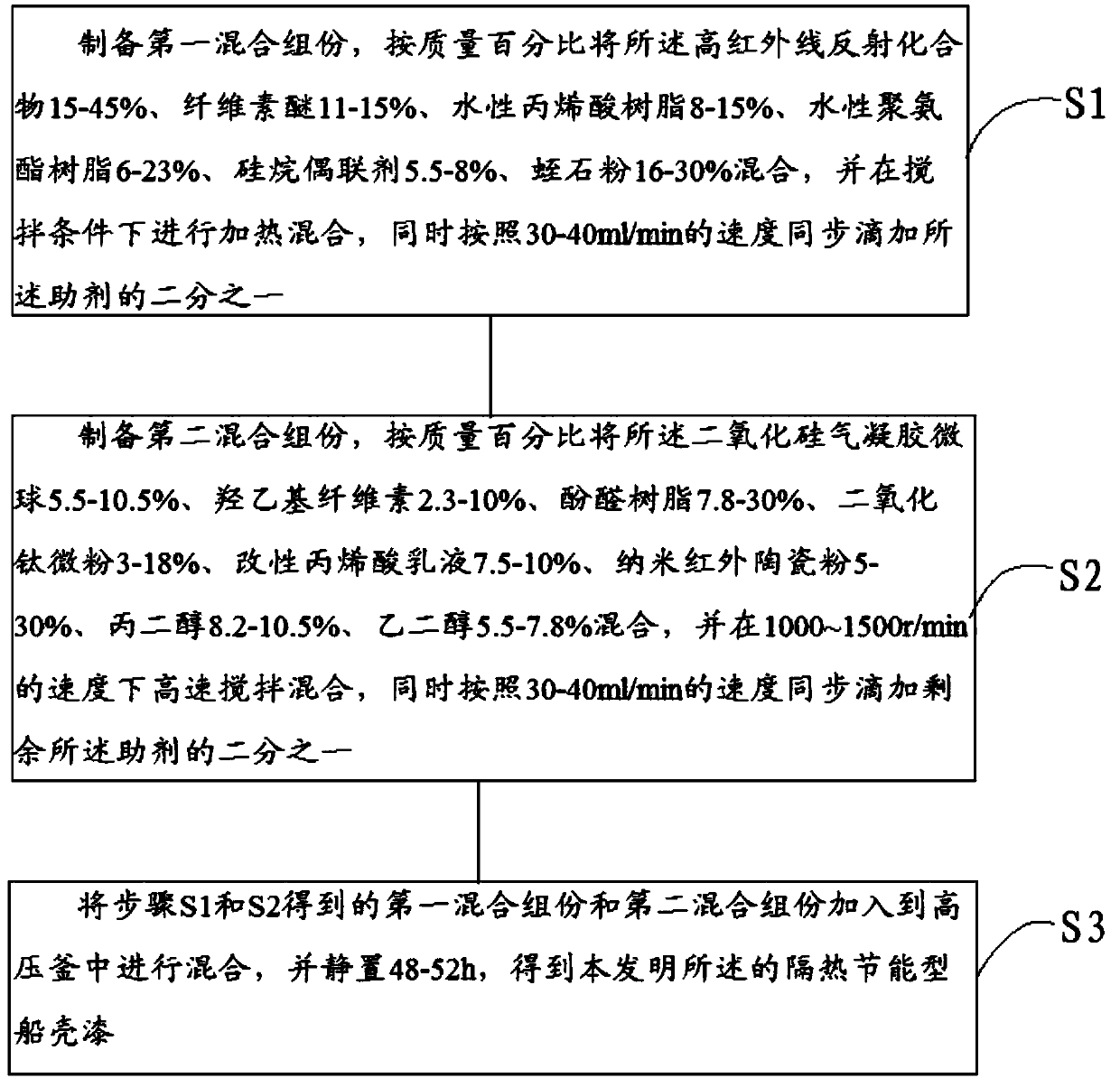

Method used

Image

Examples

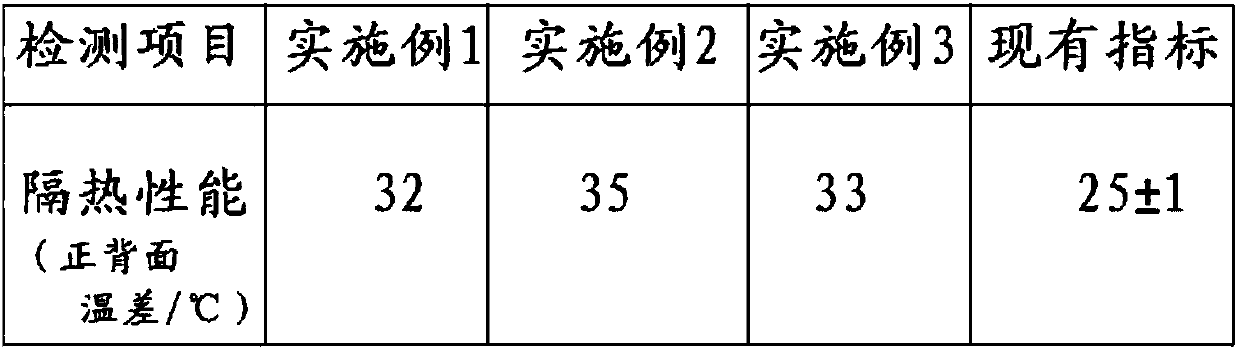

Embodiment 1

[0034]Prepare the first mixing component, mix 45% of the high infrared reflection compound, 15% of cellulose ether, 15% of water-based acrylic resin, 23% of water-based polyurethane resin, 8% of silane coupling agent, and 30% of vermiculite powder by mass percentage , and heat and mix under stirring conditions, and simultaneously drop half of the auxiliary agent synchronously at a speed of 40ml / min. Prepare the second mixing component, by mass percentage, 10.5% of the silica airgel microspheres, 10% of hydroxyethyl cellulose, 30% of phenolic resin, 18% of titanium dioxide micropowder, 10% of modified acrylic emulsion, nano 30% of infrared ceramic powder, 10.5% of propylene glycol, and 7.8% of ethylene glycol were mixed, and mixed at a high speed at a speed of 1500r / min, and at the same time, one-half of the remaining additives was synchronously added dropwise at a speed of 40ml / min. The obtained first mixed component and the second mixed component were put into an autoclave fo...

Embodiment 2

[0036] Prepare the first mixed component, and mix 45% of the high infrared reflection compound, 15% of cellulose ether, 15% of water-based acrylic resin, 2-4.8% of polyurethane resin, 1.5-4.5% of polyacrylic resin, and water-based polyurethane resin according to mass percentage 23%, 8% silane coupling agent, and 30% vermiculite powder were mixed, and heated and mixed under stirring conditions, and at the same time, 1 / 2 of the auxiliary agent was synchronously added dropwise at a speed of 40ml / min. Prepare the second mixing component, by mass percentage, 10.5% of the silica airgel microspheres, 10% of hydroxyethyl cellulose, 30% of phenolic resin, 18% of titanium dioxide micropowder, 10% of modified acrylic emulsion, nano 30% of infrared ceramic powder, 10.5% of propylene glycol, and 7.8% of ethylene glycol were mixed, and mixed at a high speed at a speed of 1500r / min, and at the same time, one-half of the remaining additives was synchronously added dropwise at a speed of 40ml / m...

Embodiment 3

[0038] Prepare the first mixed component, and mix 45% of the high infrared reflection compound, 15% of cellulose ether, 15% of water-based acrylic resin, 2-4.8% of polyurethane resin, 1.5-4.5% of polyacrylic resin, and water-based polyurethane resin according to mass percentage 23%, 8% silane coupling agent, and 30% vermiculite powder were mixed, and heated and mixed under stirring conditions, and at the same time, 1 / 2 of the auxiliary agent was synchronously added dropwise at a speed of 40ml / min. Prepare the second mixing component, by mass percentage, 10.5% of the silica airgel microspheres, 10% of hydroxyethyl cellulose, 30% of phenolic resin, 18% of titanium dioxide micropowder, 10% of modified acrylic emulsion, nano Infrared ceramic powder 30%, propylene glycol 10.5%, UV-resistant functional powder 8-12%, ethylene glycol 7.8%, mixed at a high speed of 1500r / min, and simultaneously added dropwise at a speed of 40ml / min One-half of the auxiliary agent. The obtained first m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com