Pull-ups hot welding knife roll mechanism

A technology of pull-up trousers and knife rollers, which is applied in the field of hot-welding knife-roller mechanisms for pull-up trousers, which can solve problems such as perforation and weak hot-press stitching, and achieve the effects of increasing heat dissipation area, difficult heat dissipation, and improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described in conjunction with the accompanying drawings and specific embodiments.

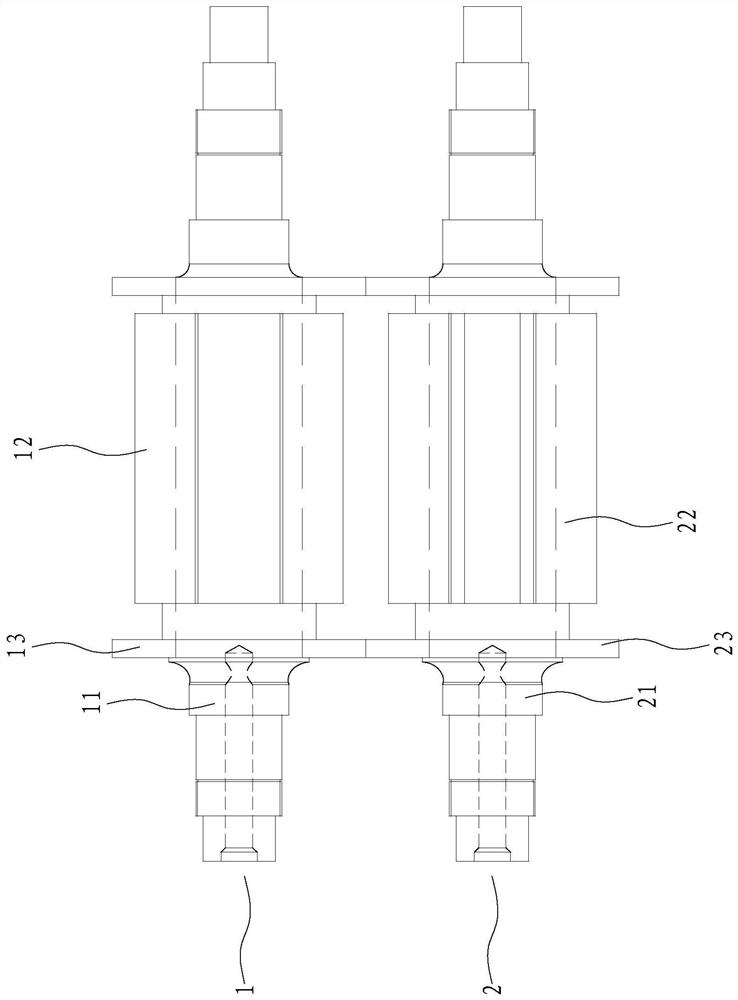

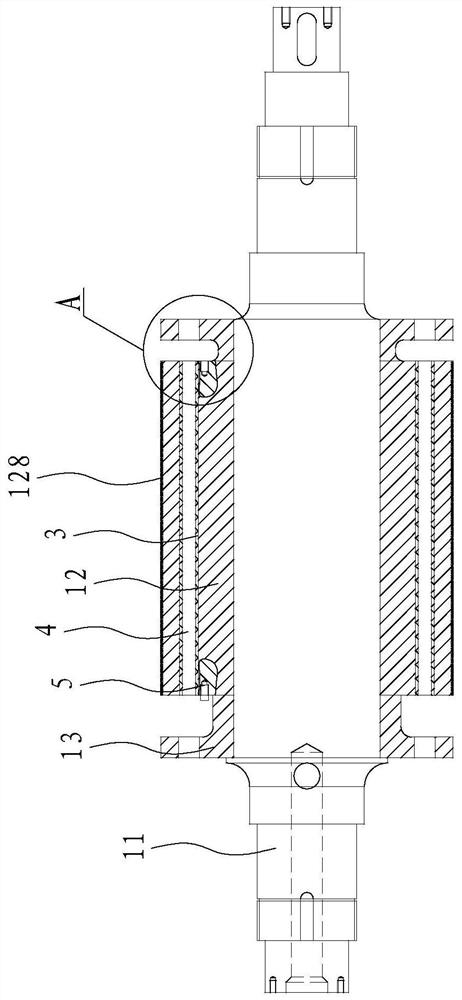

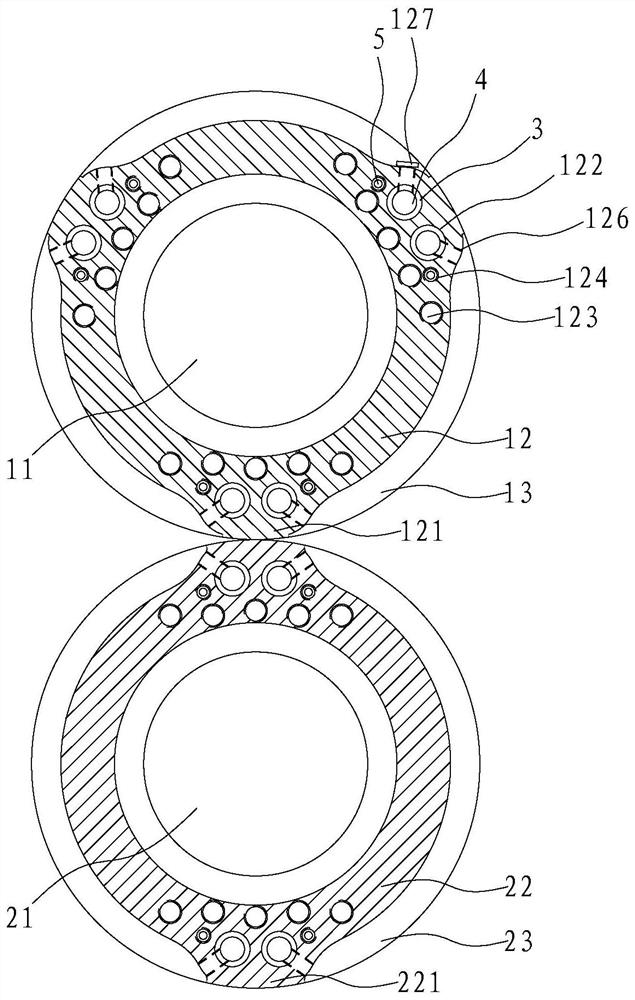

[0031] refer to Figure 1 to Figure 8, the present embodiment provides a pull-up trousers thermal welding knife roller mechanism, including a frame, a thermal knife roller 1 rotatably arranged on the frame, and a thermo-optical roller 2 rotatably arranged on the frame. The hot knife roll 1 comprises a knife roll shaft 11, a knife roll body 12 sleeved on the knife roll shaft 11, and knife roll protection rings 13 arranged on both sides of the knife roll body 12, and the knife roll body 12 protrudes outwards There are three knife roller convex parts 121, and the knife roller body 12 is located at the knife roller convex part 121. There are two knife roller electric heating pipe holes 122 along the axial direction, and the knife roller electric heating pipe holes 122 are sleeved with a knife roller Copper pipe 3, the cutter roller copper pipe 3 is prov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com