Hyperbranched solid polycarboxylate superplasticizer and preparation method thereof

A technology of polycarboxylic acid and water reducing agent, applied in the field of hyperbranched solid polycarboxylic acid water reducing agent and its preparation, can solve the problems of high preparation cost, high energy consumption, environmental pollution and the like, and achieve good dispersibility and dispersibility. Retention ability, improvement of fluidity retention, effect of lowering reaction temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

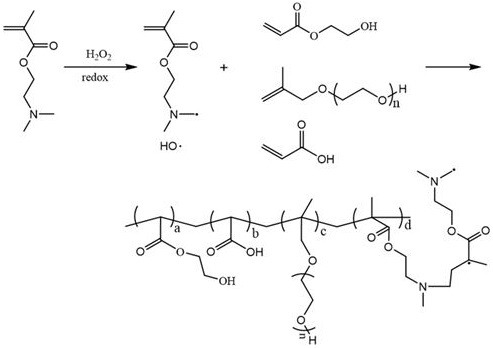

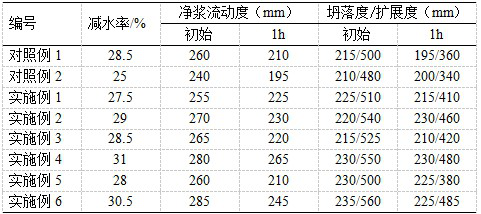

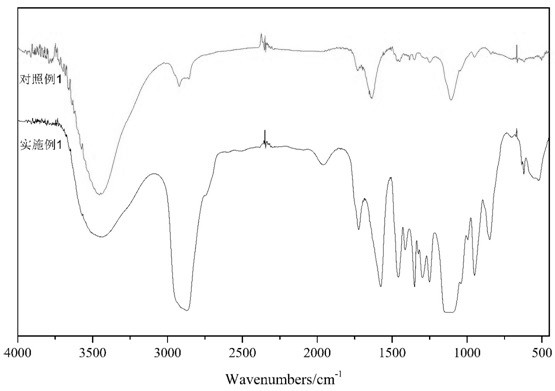

[0040]实施例1,如图1所示,

[0041]一种超支化固体聚羧酸减水剂的制备方法,其特征在于:所述超支化固体聚羧酸减水剂由以下组分制备而成:聚醚大单体、小单体溶液、链转移剂、带有双键的胺类还原剂、中和剂;总质量1000份,制备方法包括以下步骤:

[0042](1)将856份烯丙基聚氧乙烯醚加入三口烧瓶,升温至55℃,开启搅拌使大单体完全融化。

[0043](2)大单体完全融化后测定烧瓶内温度,控制温度在40℃,温度稳定后加入氧化剂8份过氧化氢。

[0044](3)待10分钟后开始滴加小单体溶液和带有双键的胺类还原剂,小单体溶液滴加时间为2.5h,小单体溶液由2.5份巯基乙酸、90份丙烯酸、30份丙烯酸羟乙酯组成;小单体滴加10分钟后,滴加8份甲基丙烯酸二甲氨乙酯,滴加时间为2.5h。

[0045](4)滴加过程中做好反应釜的保温工作,不需要加热。滴加结束后保温熟化1h,熟化结束后缓慢加入5份氢氧化钠进行中和,冷却切片后,即得超支化固体聚羧酸减水剂。

Example Embodiment

[0046]实施例2

[0047]一种超支化固体聚羧酸减水剂的制备方法,其特征在于:所述超支化固体聚羧酸减水剂由以下组分制备而成:聚醚大单体、小单体溶液、链转移剂、带有双键的胺类还原剂、中和剂;总质量1000份,制备方法包括以下步骤:

[0048](1)将828份甲基烯丙基聚氧乙烯醚加入三口烧瓶,升温至60℃,开启搅拌使大单体完全融化。

[0049](2)大单体完全融化后测定烧瓶内温度,控制温度在45℃,温度稳定后加入氧化剂22份过氧化苯甲酰。

[0050](3)待10分钟后开始滴加小单体溶液和带有双键的胺类还原剂,小单体溶液滴加时间为2h,小单体溶液由3份巯基丙酸、84份甲基丙烯酸、35份丙烯酸羟丙酯组成;小单体滴加10分钟后,滴加12份甲基丙烯酸对(N,N-二甲氨基)苄酯,滴加时间为2h。

[0051](4)滴加过程中做好反应釜的保温工作,不需要加热。滴加结束后保温熟化2h,熟化结束后缓慢加入10份三乙醇胺进行中和,冷却切片后,即得超支化固体聚羧酸减水剂。

Example Embodiment

[0052]实施例3

[0053]一种超支化固体聚羧酸减水剂的制备方法,其特征在于:所述超支化固体聚羧酸减水剂由以下组分制备而成:聚醚大单体、小单体溶液、链转移剂、带有双键的胺类还原剂、中和剂;总质量1000份,制备方法包括以下步骤:

[0054](1)将820份乙烯基丁基醚聚氧乙烯醚加入三口烧瓶,升温至40℃,开启搅拌使大单体完全融化。

[0055](2)大单体完全融化后测定烧瓶内温度,控制温度在35℃,温度稳定后加入氧化剂13份过氧化十二酰。

[0056](3)待10分钟后开始滴加小单体溶液和带有双键的胺类还原剂,小单体溶液滴加时间为1h,小单体溶液由7份乙烯基磺酸钠、40份丙烯酸、60份马来酸、25份丙烯酸甲酯组成;小单体滴加10分钟后,滴加15份4'-(二甲氨基)丙烯酰苯胺,滴加时间为1h。

[0057](4)滴加过程中做好反应釜的保温工作,不需要加热。滴加结束后保温熟化3h,熟化结束后缓慢加入8份二乙醇钠进行中和,冷却切片后,即得超支化固体聚羧酸减水剂。

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com