Quick clamp for milling thin-walled tube type workpiece

A thin-walled tube and workpiece technology is applied in the field of quick fixtures for milling thin-walled tubular workpieces, and can solve problems such as large deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

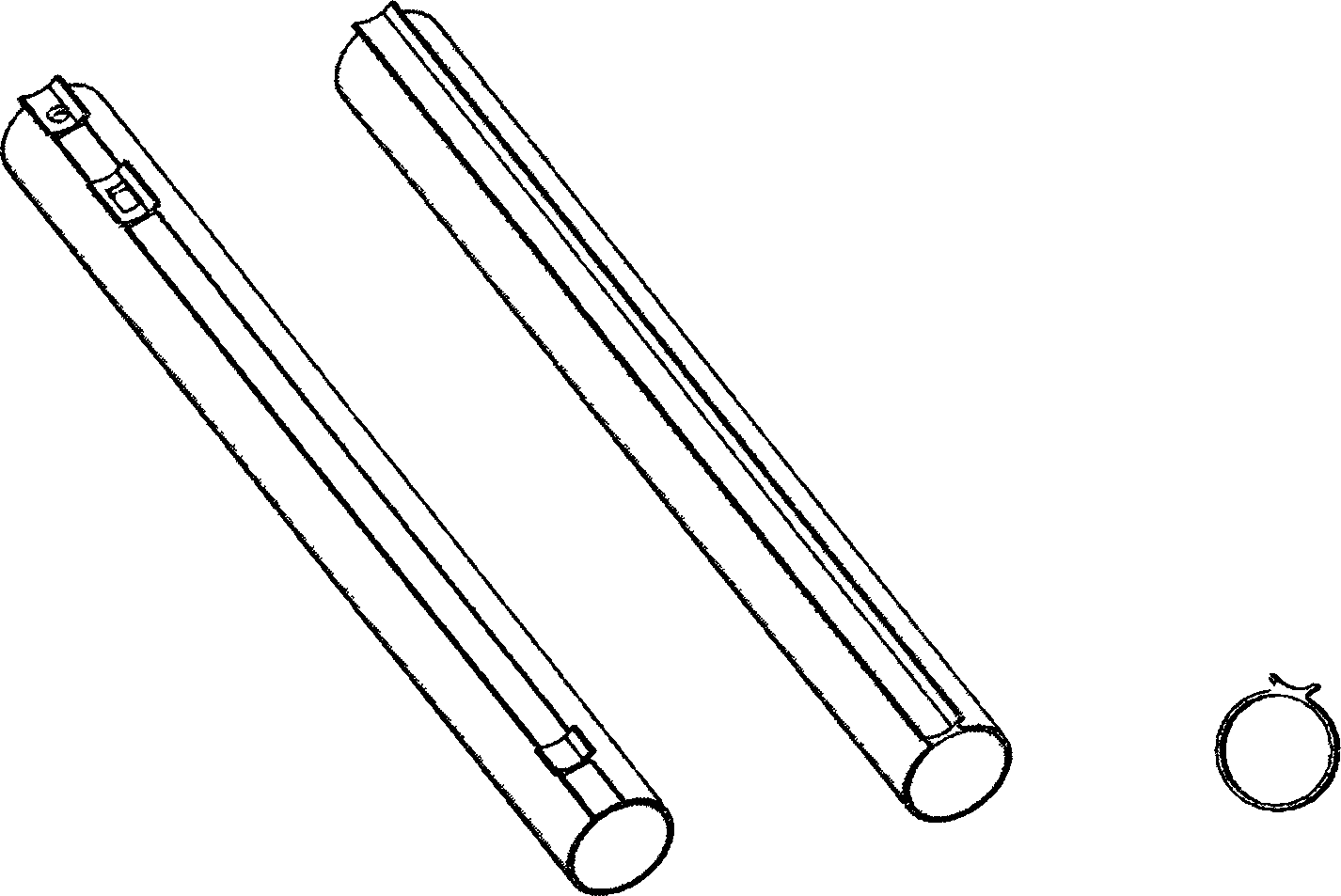

[0010] Such as figure 1 As shown, a is the thin-walled aluminum tube to be processed, b is the processed thin-walled aluminum tube, c is the end face of the thin-walled aluminum tube, and the wall thickness is very thin.

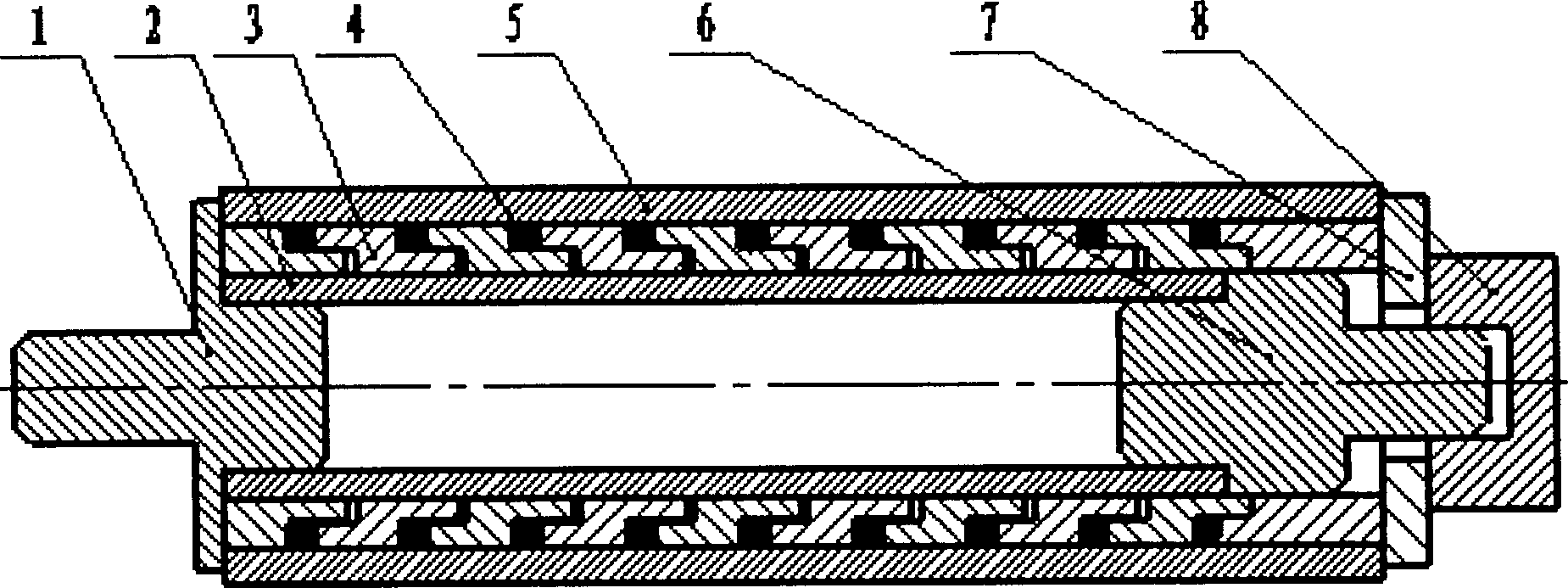

[0011] Such as figure 2 As shown, the left positioning mandrel (1) and the right positioning mandrel (6) are connected together with the support tube (2) in the form of interference fit. Piston rings (3) and O-shaped rubber sealing rings (4) are alternately set on the support tube (2).

[0012] During work, put the thin-walled aluminum tube (5) on the support tube (2), and insert the left positioning mandrel (1) together with the thin-walled aluminum tube (5) into the positioning hole of the positioning fixture. Then, load onto the pressing plate (7) on the right side, and the clamping jig (8) is pressed on the pressing plate (7) by the toggle clamp.

[0013] The pressure plate (7) moves to the left, pushing the piston ring (3) to move to the left in tur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com